Vibration damping support structure, compressor and air conditioner

A vibration damping support and compressor technology, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of reduced stiffness, thinner rubber feet, increased noise, etc., and achieves increased radial Or tangential stiffness, increase the contact area, increase the effect of vibration isolation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

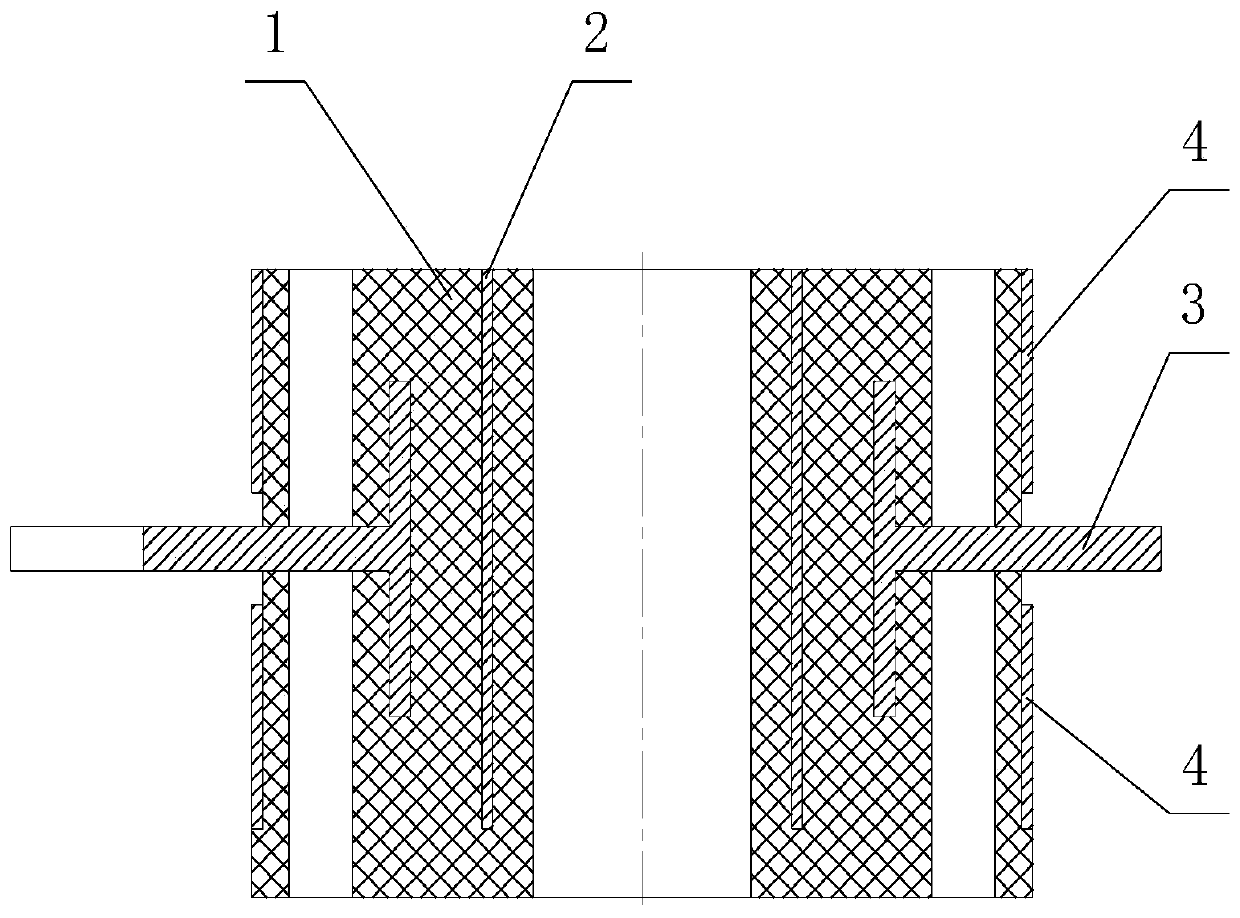

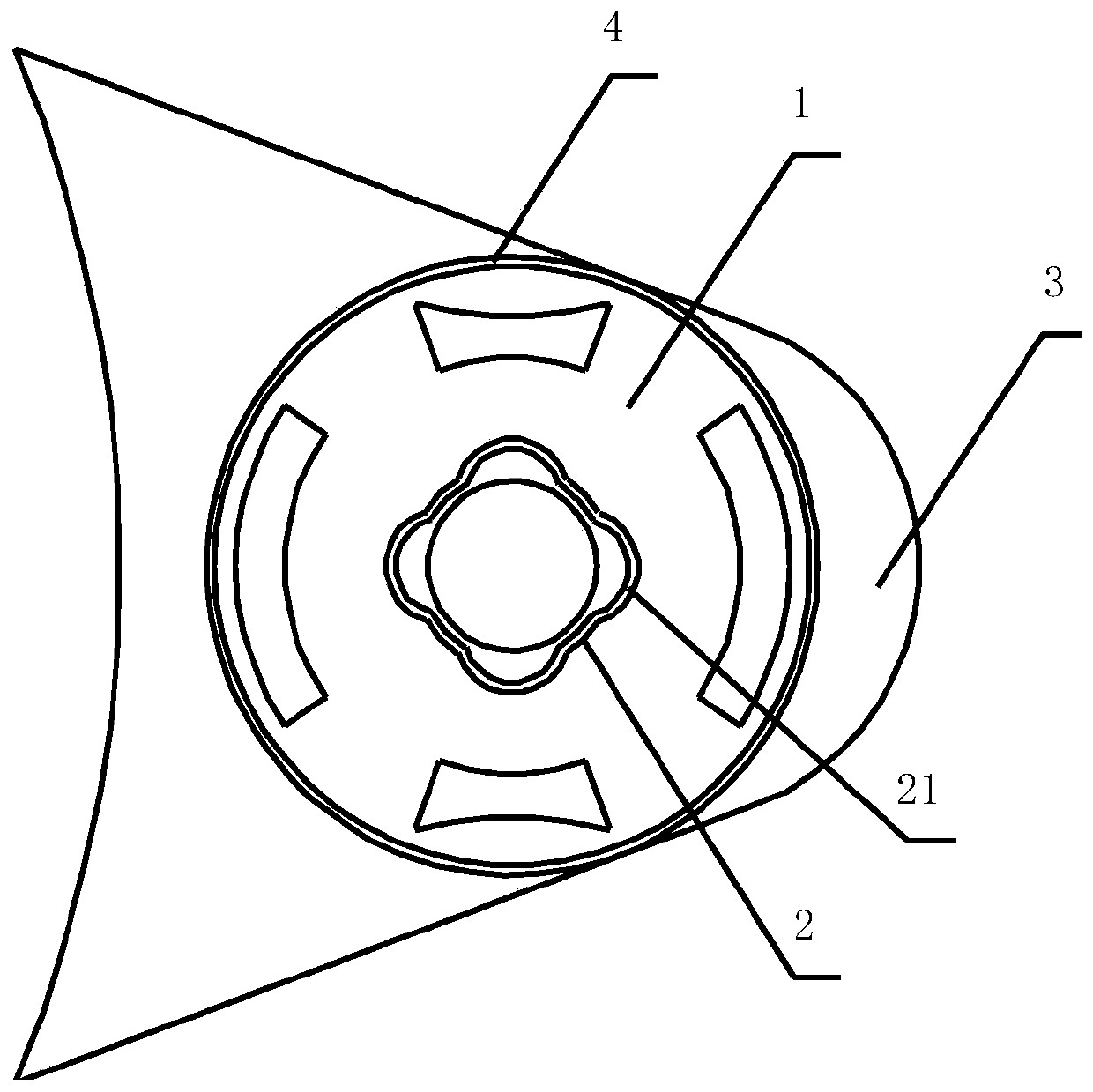

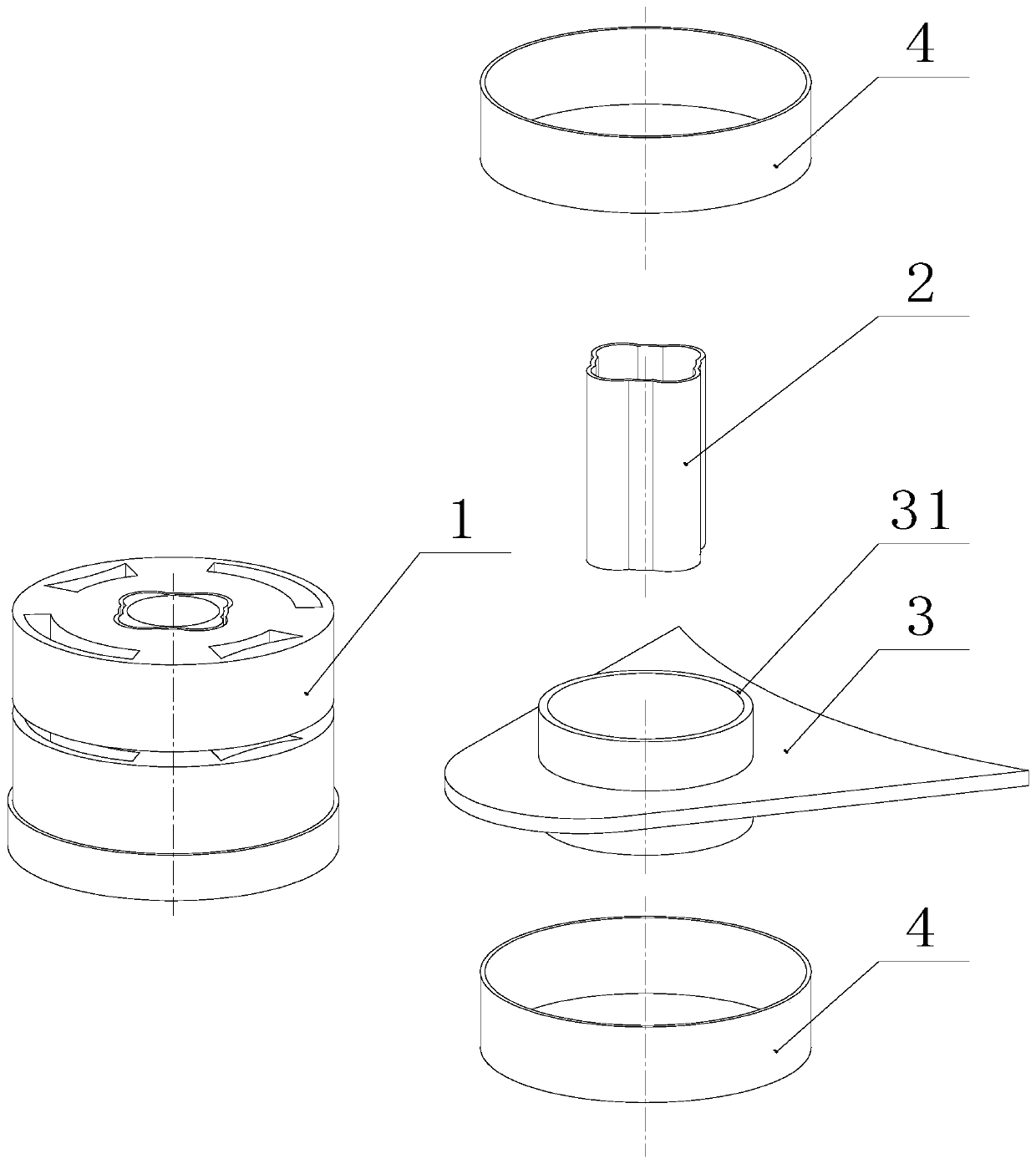

[0027] see in conjunction Figure 1 to Figure 5 As shown, according to an embodiment of the present invention, a vibration-damping support structure includes a support foot 3 and a vibration-damping pad 1. The support foot 3 includes a flat plate with holes and a reinforcing tube 31, and the reinforcing tube 31 is passed through the In the hole; the reinforcing tube 31 is arranged in the shock absorbing pad 1 .

[0028] The supporting foot 3 is made of a flat plate and a reinforcing tube 31, wherein the reinforcing tube 31 passes through the hole on the plate; The contact area of the vibrating pad 1 increases the radial and tangential stiffness, so it can withstand greater force and meet the requirement of large stiffness required by low-frequency vibration.

[0029] The reinforcing tube 31 is fixedly connected to the flat plate, and the inner and outer walls of the reinforcing tube 31 are bonded and fixed with the vibration-damping pad 1 to further increase the rigidity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com