Glass fiber reinforced plastics type acid and alkali resistant fan

A technology of acid and alkali resistance and glass fiber reinforced plastics, applied in mechanical equipment, friction generators, machines/engines, etc., can solve problems such as poor use effect, inability to absorb particulate matter, and inability to eliminate bacteria, so as to protect health and improve sterilization effect. , the effect of improving air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

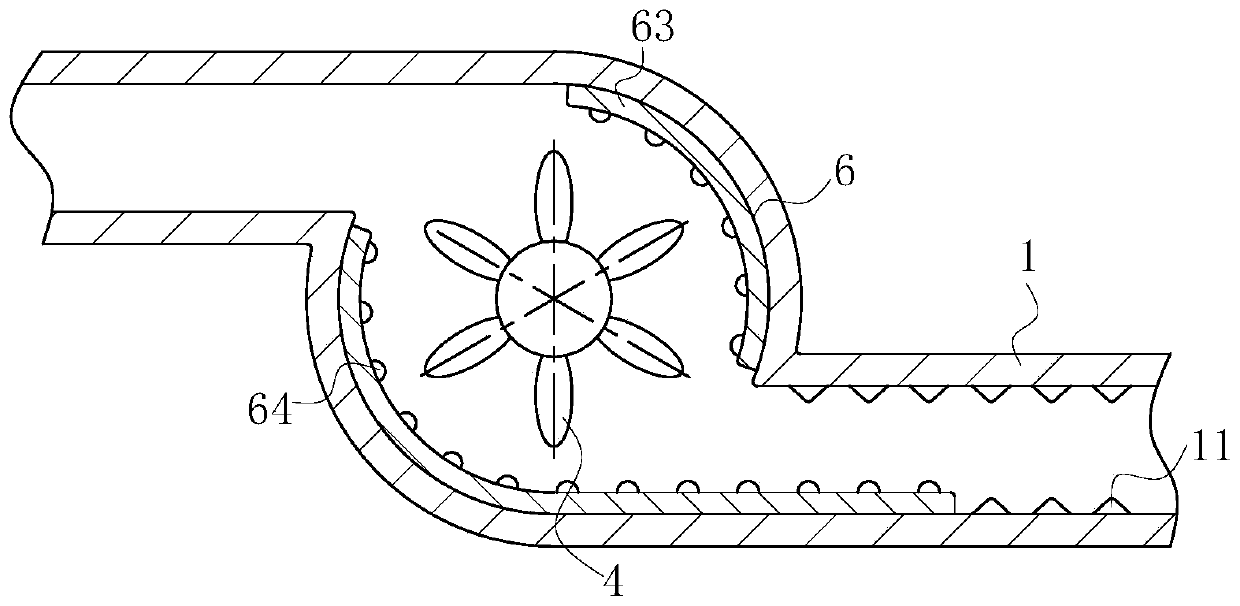

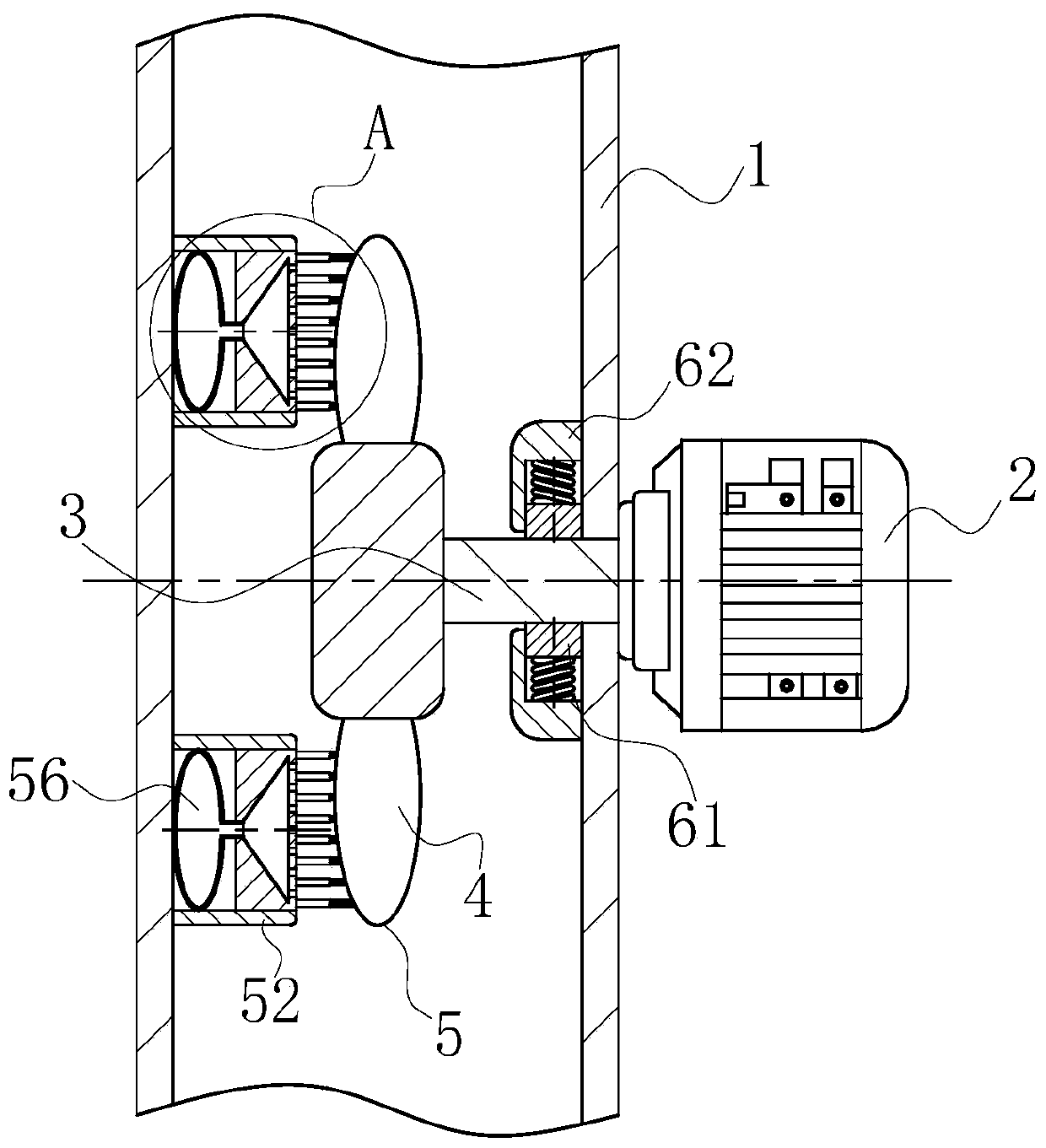

[0020] use Figure 1-Figure 5 A fiberglass acid and alkali resistant fan according to an embodiment of the present invention is described as follows.

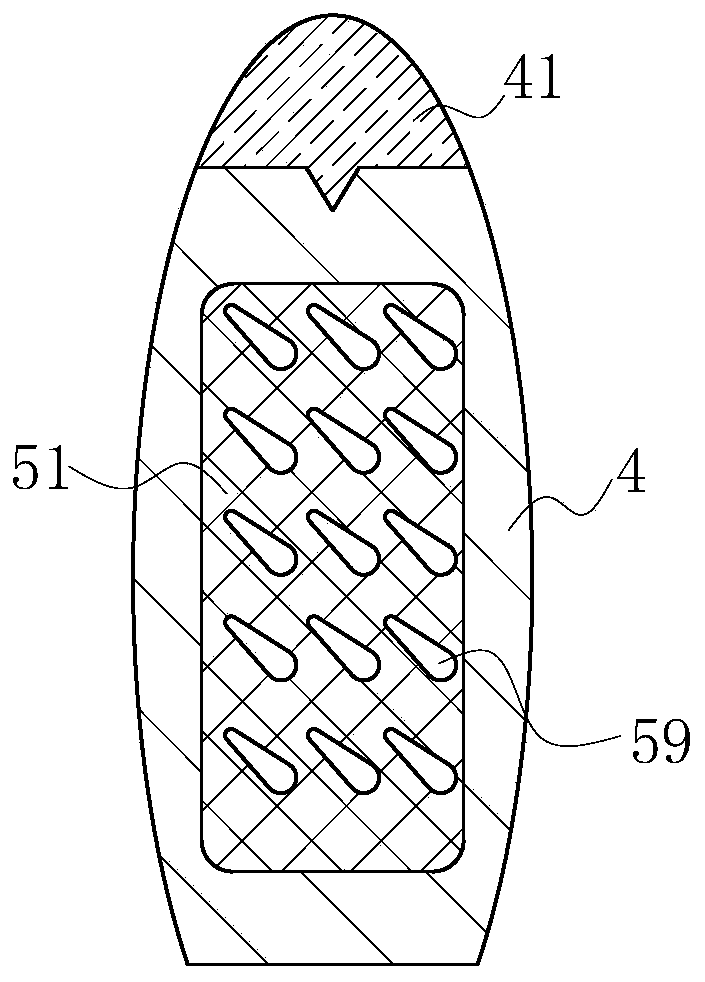

[0021] Such as Figure 1-Figure 5 As shown, a fiberglass acid and alkali-resistant fan according to the present invention includes a housing 1, a motor 2, a rotating rod 3, fan blades 4, a dust suction mechanism 5 and a sterilizing mechanism 6; the inner end of the housing 1 is A motor 2 is fixedly installed on the surface; the front end of the motor 2 is rotatably connected to a rotating rod 3; the rotating rod 3 is arranged in the housing 1, and the front end of the rotating rod 3 is fixedly installed with a fan blade 4; the fan blade 4 is made of stainless steel The front end of the fan blade 4 is provided with a dust suction mechanism 5; the dust suction mechanism 5 includes a rubber plate 51, a mounting frame 52, a mounting block 53, a mounting rod 54 and fur 55; the rubber plate 51 is inlaid and connected to the fan blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com