Air supply device

An air supply device and fan technology, which is applied to pump devices, components of pumping devices for elastic fluids, non-variable volume pumps, etc., can solve the problems of low air output, not easy to carry, noise, etc. The effect of uniformity, increasing air volume and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

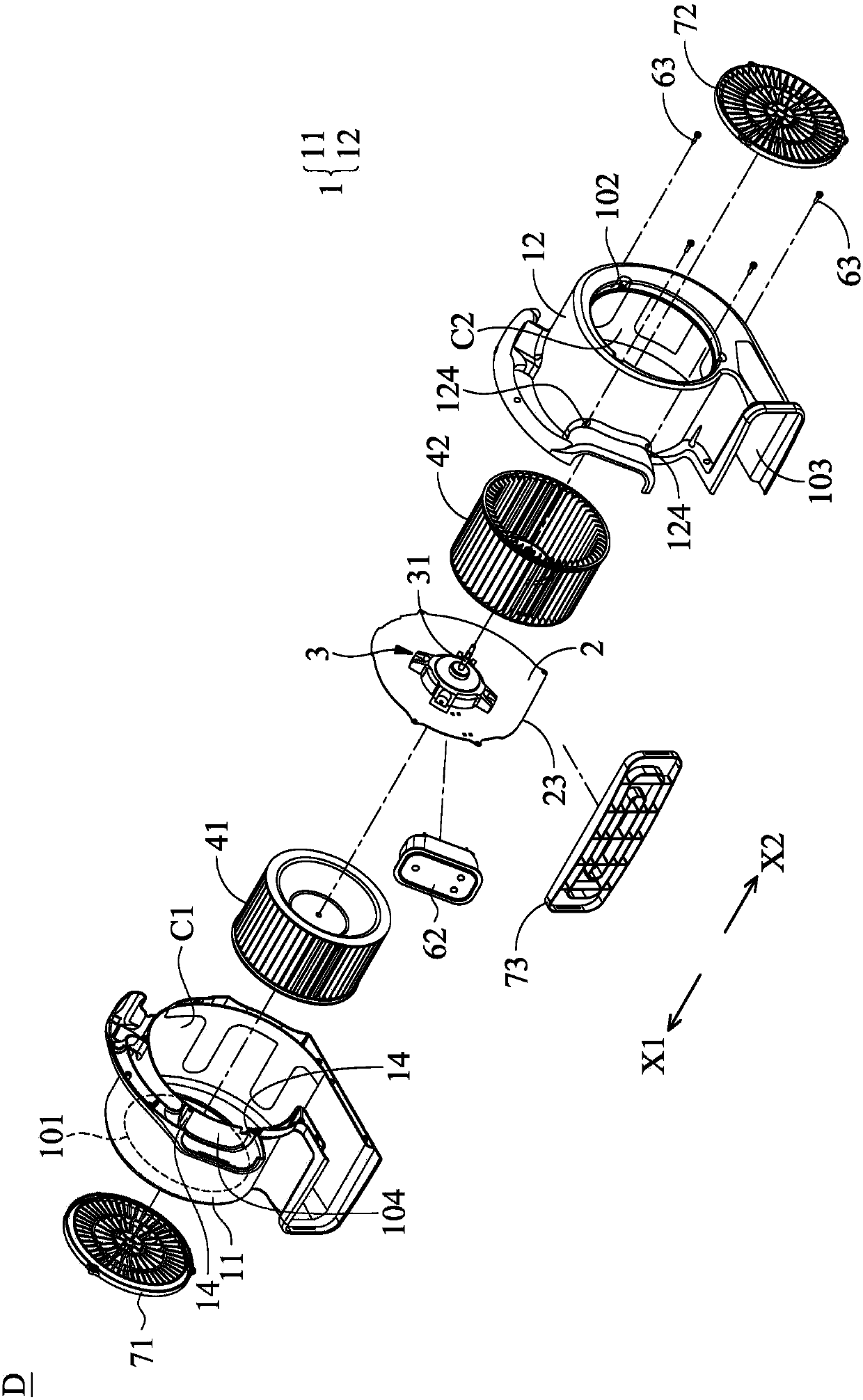

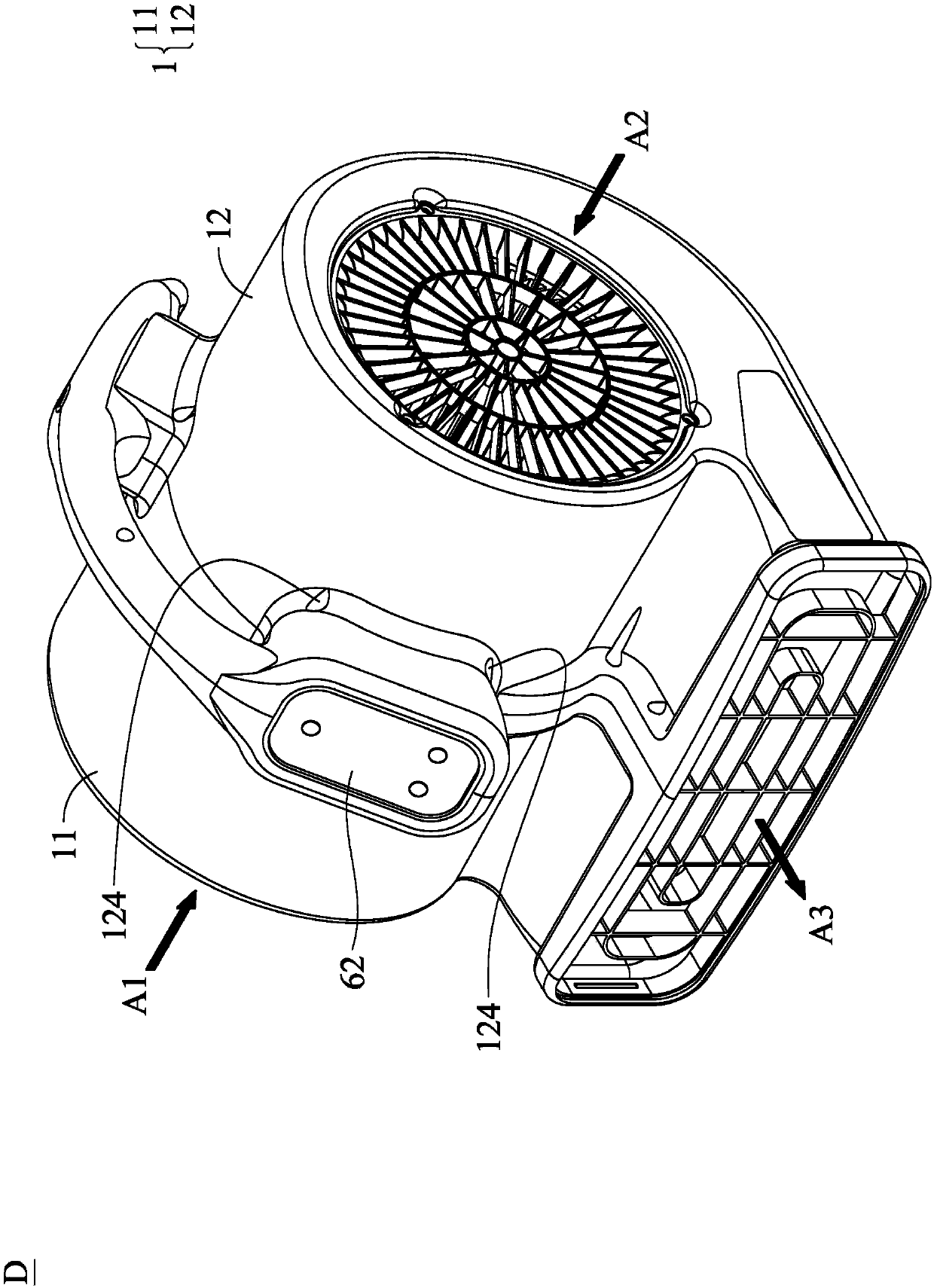

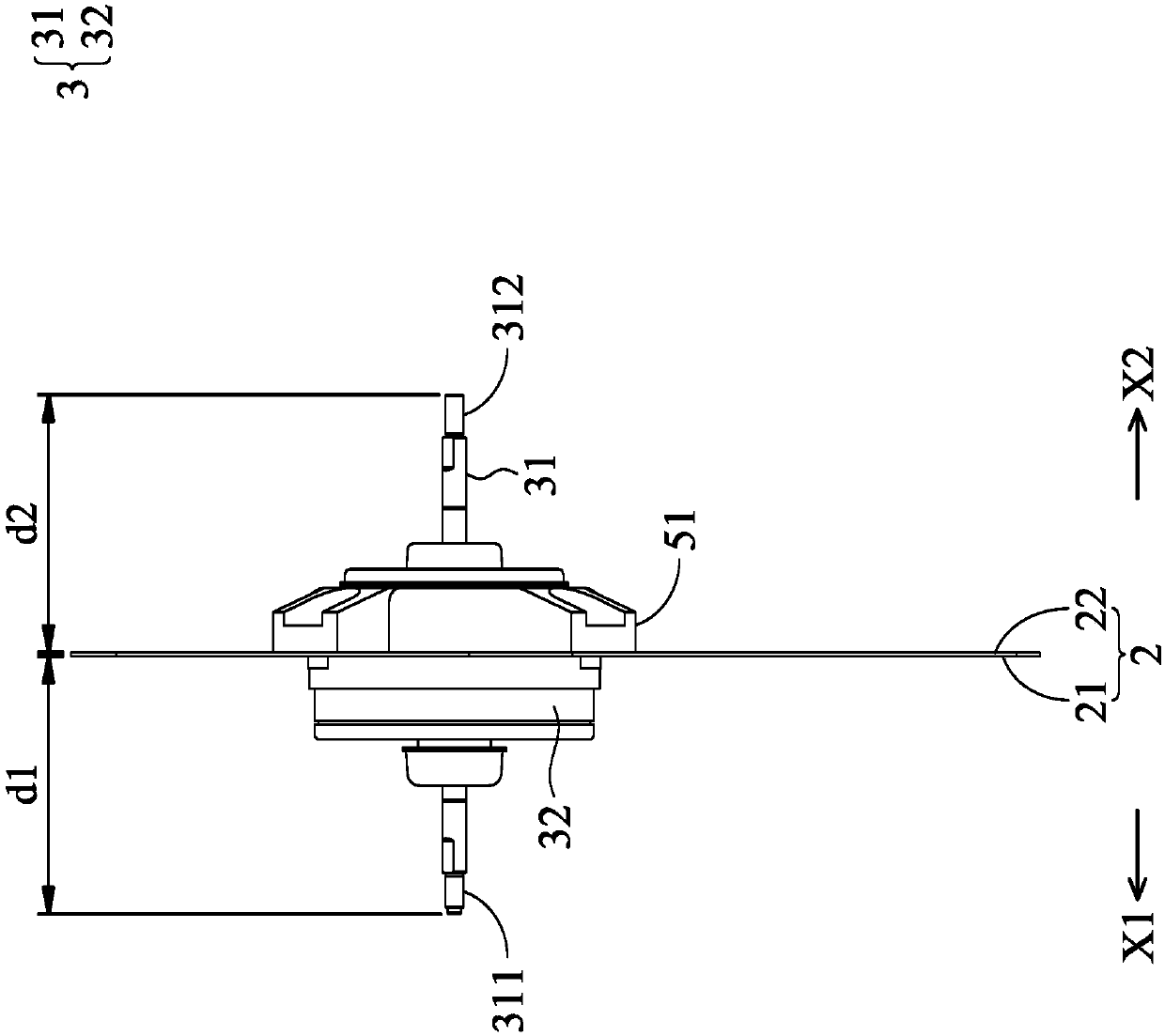

[0074] Figure 1A is an exploded perspective view showing an air blower according to an embodiment of the present invention. Figure 1B It is an assembled view showing an air blower according to an embodiment of the present invention. Referring to FIGS. 1A and 1B , an air blower D according to an embodiment of the present invention includes a housing 1 , a partition 2 , a coaxial motor 3 , a first fan 41 and a second fan 42 . The housing 1 has a first air inlet 101, a second air inlet 102 and an air outlet channel 103, the housing 1 includes a first housing part 11 and a second housing part 12, the first air inlet 101 forms In the first casing part 11 , the second air inlet 102 is formed in the second casing part 12 . The partition 2 is disposed between the first housing part 11 and the second housing part 12 . In an embodiment of the present invention, the first fan and the second fan have the same radius or the same chord length; the size of the first air inlet is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com