Sheet metal hexagonal nut

A hexagonal nut and sheet metal technology, applied in the field of sheet metal hexagonal nuts, can solve the problems of high manufacturing difficulty, high manufacturing requirements and high cost of cylindrical external threads and hexagonal nuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

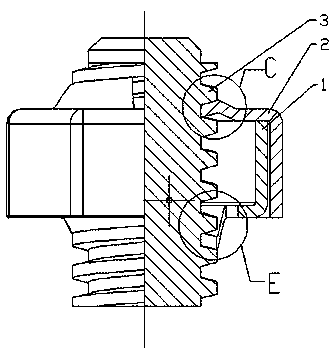

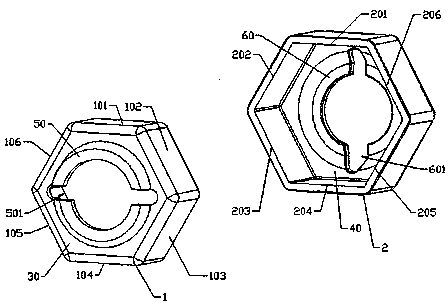

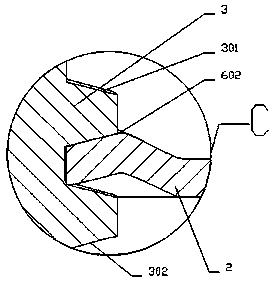

[0025] Such as Figure 1-7 The illustrated sheet metal hexagon nut includes an inner hexagon nut 1 and an outer hexagon nut 2, the inner hexagon nut 1 is embedded in the outer hexagon nut 2, and one side of the inner hexagon nut 1 is provided with an inner sheet metal substrate 30, so One side of the inner sheet metal substrate 30 is provided with an inner sheet metal thread 50, and the middle part of the inner sheet metal thread 50 is provided with a first opening 501, and one side of the outer hex nut 2 is provided with an outer sheet metal substrate 40, and the outer hexagon nut 2 is provided with an outer sheet metal substrate 40. An outer sheet metal thread 60 is provided on one side of the sheet metal substrate 40 , and a second opening 601 is provided in the middle of the outer sheet metal thread 60 .

[0026] In this embodiment, by setting the cylindrical external thread 3, the inner hexagon nut 1 and the outer hexagon nut 2, a sensor and a self-locking device can be i...

Embodiment 2

[0028] Such as Figure 1-7 As shown, the inner hexagon nut 1 is provided with a first outer surface 101 of the inner hexagon nut, and one side of the first outer surface 101 of the inner hexagon nut is provided with a second outer surface 102 of the inner hexagon nut, and the second outer surface of the inner hexagon nut One side of 102 is provided with the third outer surface 103 of the inner hexagon nut, the third outer surface 103 of the inner hexagon nut is provided with the fourth outer surface 104 of the inner hexagon nut, and one side of the fourth outer surface 104 of the inner hexagon nut is arranged There is a fifth outer surface 105 of an inner hexagon nut, one side of the fifth outer surface 105 of the inner hexagon nut is provided with a sixth outer surface 106 of an inner hexagon nut, the first outer surface 101 of the inner hexagon nut, the second outer surface of the inner hexagon nut Surface 102, the third outer surface 103 of the inner hexagon nut, the fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com