Full automatic pre-attaching device for conducive film on mobile phone screen

A conductive adhesive film and mobile phone screen technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of ACF and LCD attachment deviation, ACF is prone to offset, etc., to improve attachment accuracy, ensure accuracy, Avoid the effect of stationarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

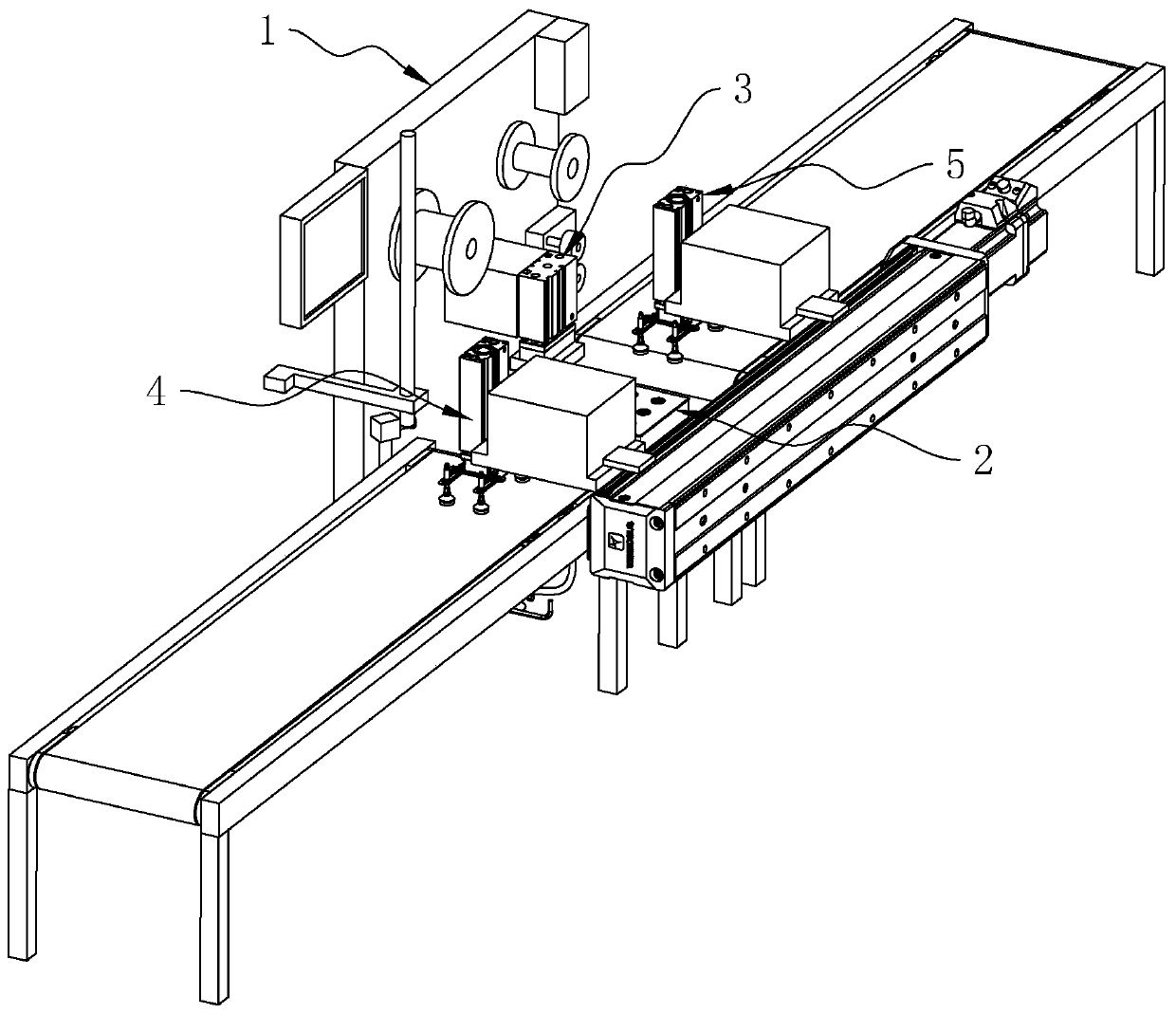

[0036] A fully automatic pre-attachment device for conductive adhesive film for mobile phone screens, such as figure 1 As shown, it includes a frame 1, on which is installed a carrying platform 2 for carrying the LCD, an attachment mechanism 3 for attaching the ACF to the LCD on the carrying platform 2, and for absorbing the LCD to be processed The loading suction cup mechanism 4 to the carrier table 2 and the unloading suction cup mechanism 5 for transferring the LCD after attaching the ACF to the next process. Wherein, the feeding suction cup mechanism 4 and the unloading suction cup mechanism 5 are consistent with the suction cup installation structure disclosed in the application number "CN201720818455.3", and will not be repeated here.

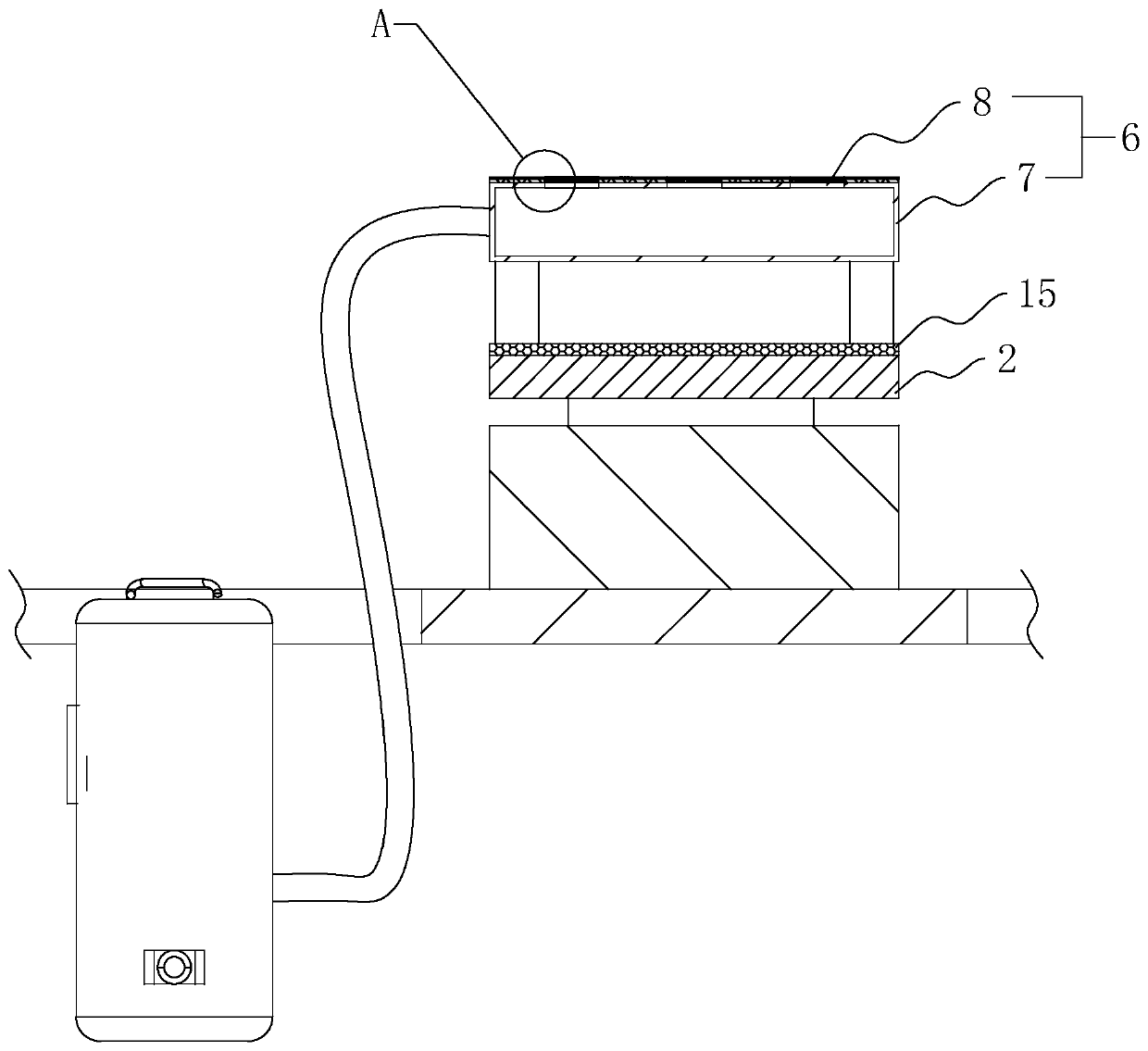

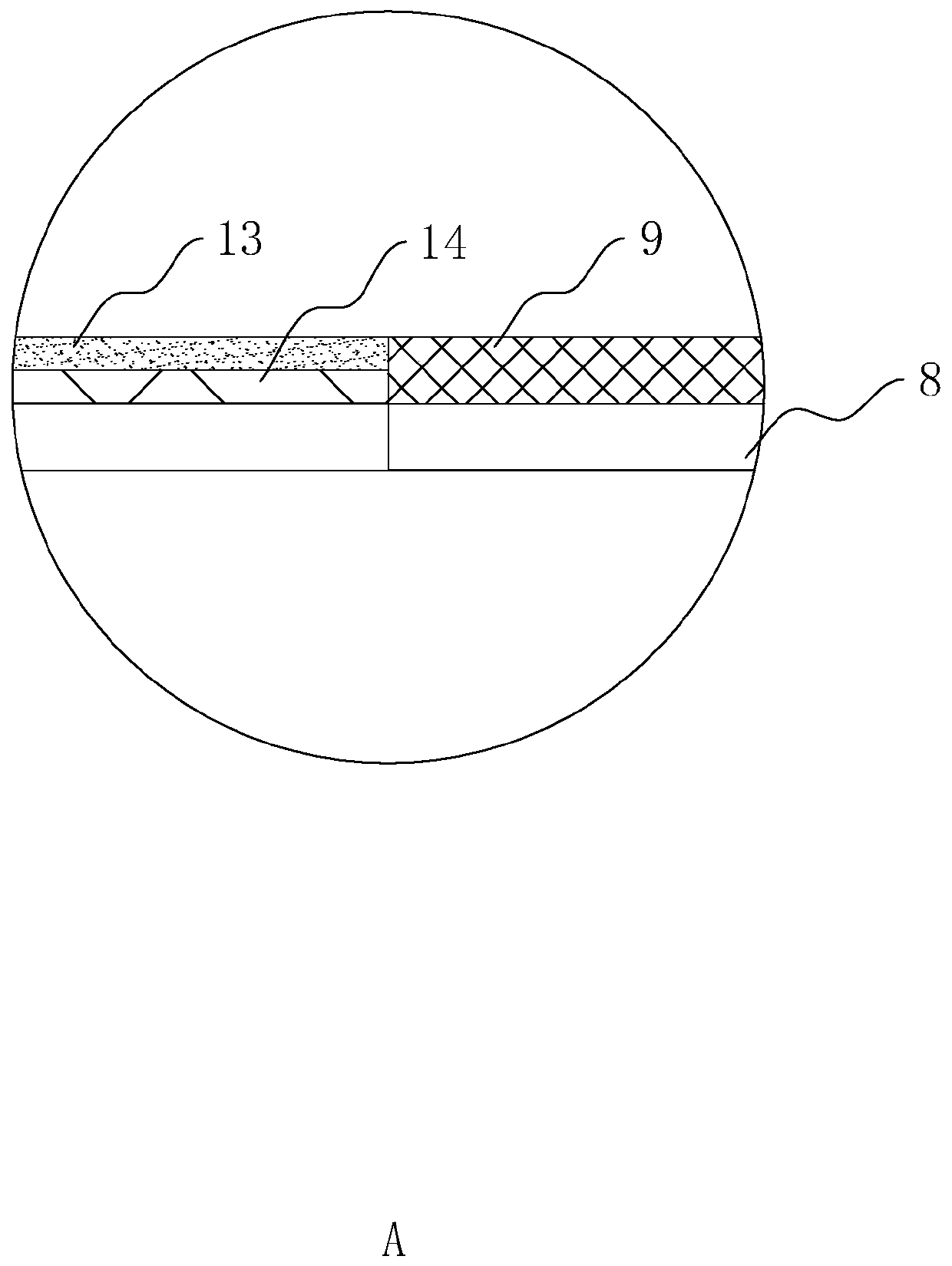

[0037] like figure 2 As shown, the mounting table 2 is provided with an attachment jig 6 for positioning the LCD. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com