Environment temperature control system of battery cell test, and control method

An ambient temperature and control system technology, applied in the direction of temperature control, electric temperature control, control/regulation system, etc., can solve the problem of low utilization rate per unit area, increased cost, and reduced temperature control accuracy of battery cycle life test, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

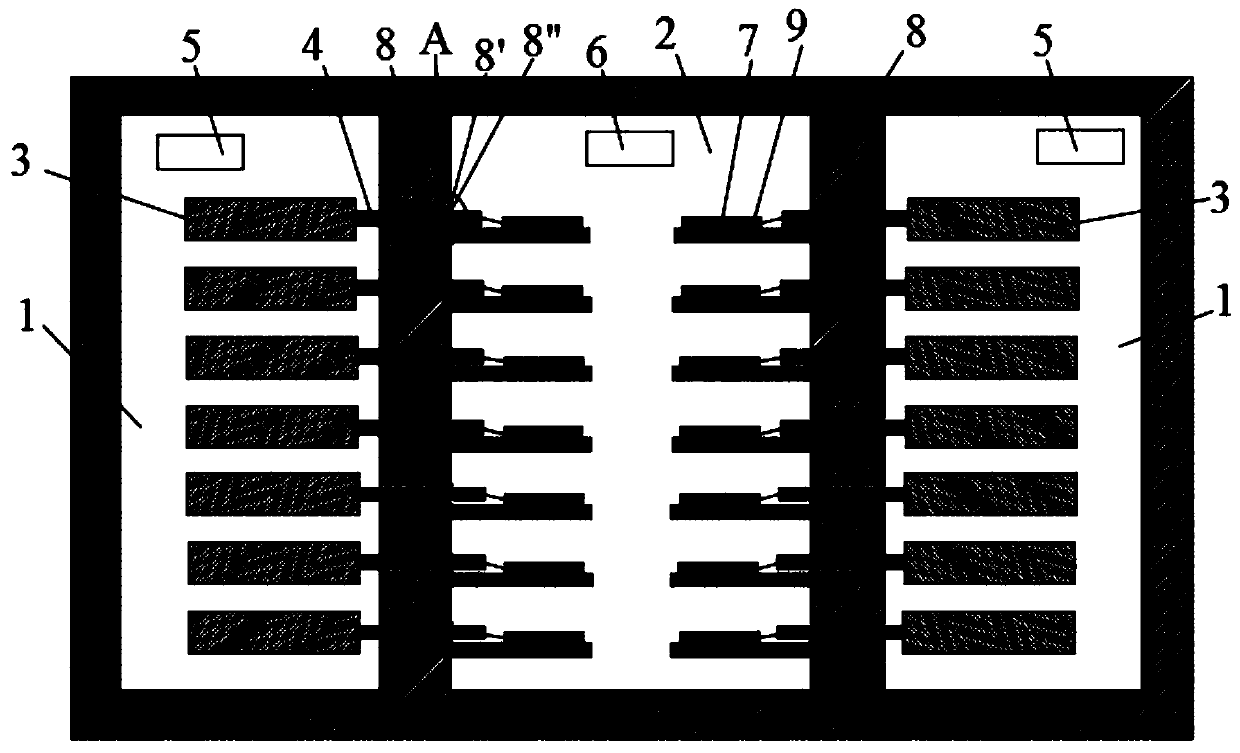

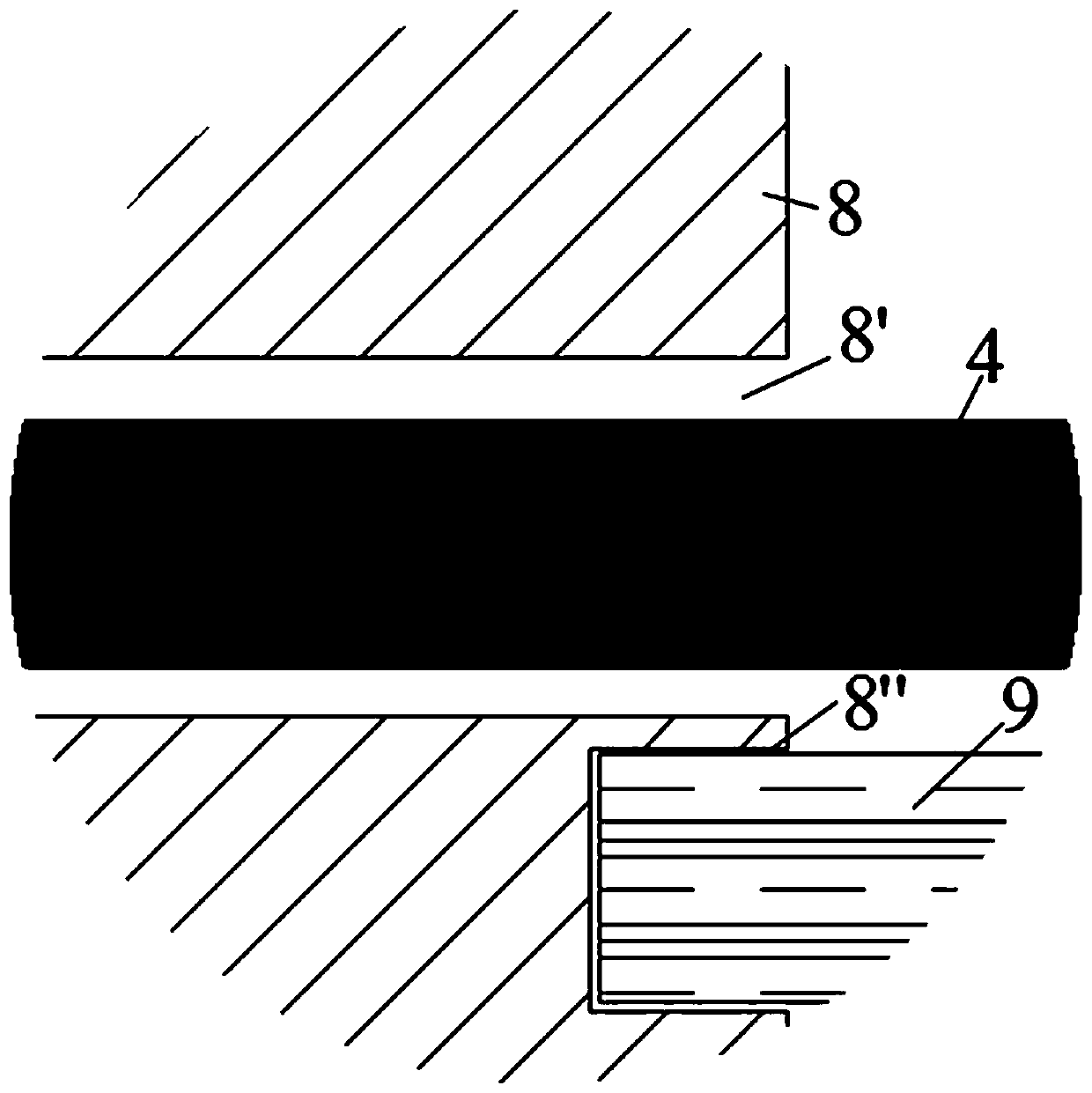

[0032] like Figure 1-2 As shown, an environment temperature control system for cell testing includes at least one first airtight test area 1 and at least one second airtight test area 2, the first airtight test area 1 is provided with a first temperature adjustment device 5 and at least one The battery testing equipment 3 , the second airtight testing area 2 is provided with a second temperature regulating device 6 and at least one battery 7 , and the battery testing equipment 3 is electrically connected to the battery 7 through a test line 4 . In practical applications, the first airtight test area 1 and the second airtight test area 2 are composed of walls, that is, it can be understood that two rooms are separated by a wall; The temperature of the working environment of the equipment 3 is regulated, and the second temperature regulating device 6 regulates the temperature of the working environment of the battery cell 7, so as to avoid the influence of the heat generated by...

Embodiment 2

[0044] like Figure 1-2 As shown, a control method of the ambient temperature control system of the cell test in Embodiment 1 includes the following steps:

[0045] S1. Provide at least one first airtight test area 1 and at least one second airtight test area 2, and set up multiple test groups to reduce costs and improve test efficiency;

[0046] S2. Place at least one cell testing device 3 in the first airtight test area 1, place at least one battery cell 7 to be tested in the second airtight test area 2, set multiple test units in a test group, and test multiple battery cells 7 at the same time Conduct tests to improve test efficiency;

[0047] S3. Set the temperature of the first airtight section 1 as the first preset temperature, and set the temperature of the second airtight test area 2 as the second preset temperature;

[0048] S4. Use the battery cell testing equipment 3 in the first airtight section 1 to test the battery cell 7 in the second airtight test area 2, rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com