Zero cross controller of reactive compensator

A compensation device and controller technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, control/regulation systems, etc., can solve reference voltage waveform distortion, reactive power compensation device burnout, and reactive power compensation device difficulty. Accurately track and adjust problems to achieve the effect of reducing inrush current and overcoming time lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

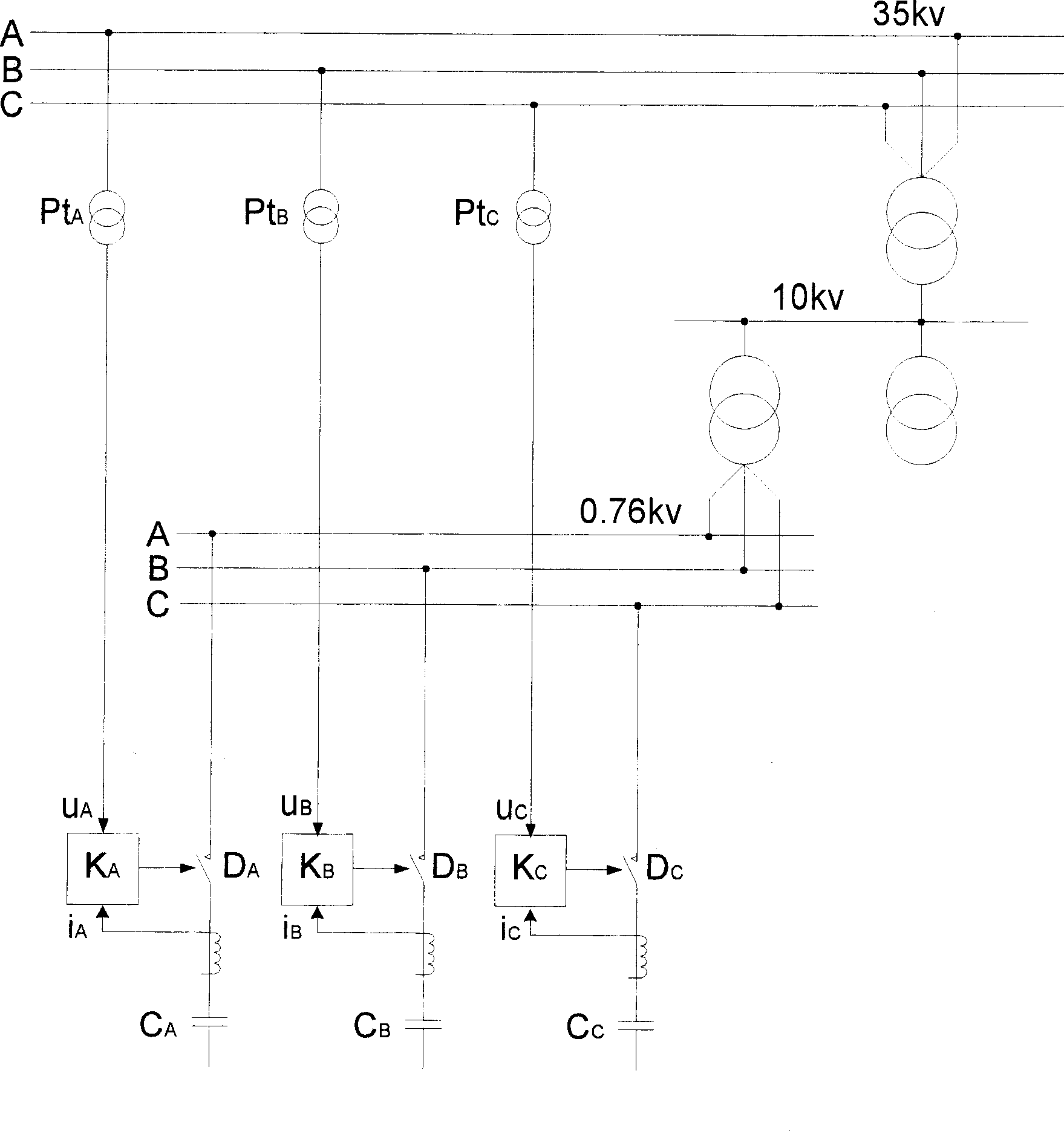

[0007] Embodiment 1: Referring to the accompanying drawings, a zero-crossing controller K of a reactive power compensation device A 、K B 、K C , it K A 、K B 、K C is input with a power frequency reference voltage signal u A , u B , u C , according to which control the low-voltage vacuum circuit breaker D of the corresponding reactive power compensation device A 、D B 、D C The reference switching time is the reference voltage signal u A , u B , u C At a certain moment between 85° and 95°, each controller K A 、K B 、K C is also input into a current signal i of the controlled compensation branch A i B i C , adjust the corresponding low-voltage vacuum circuit breaker D according to the size and direction of the inrush current during switching A 、D B 、D C at the switching moment, the high-frequency non-cycle component in the inrush current value is zero, the inrush current value tends to the fundamental wave value, and the current signal i A i B i C When it is ze...

Embodiment 2

[0008] Embodiment 2: Referring to the accompanying drawings, the zero-crossing controller of the reactive power compensation device, each of the controllers K A 、K B 、K C Both pass through a high voltage sampling transformer Pt A 、Pt B 、Pt C Obtain power frequency reference voltage signal u from 35kv power bus A , u B , u C .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com