Production line risk scheduling method for sudden large faults of equipment

A scheduling method and failure risk technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problems of large impact, difficult to reflect the risk level of production line equipment operation, low probability of occurrence, etc., to achieve the effect of solving serious harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

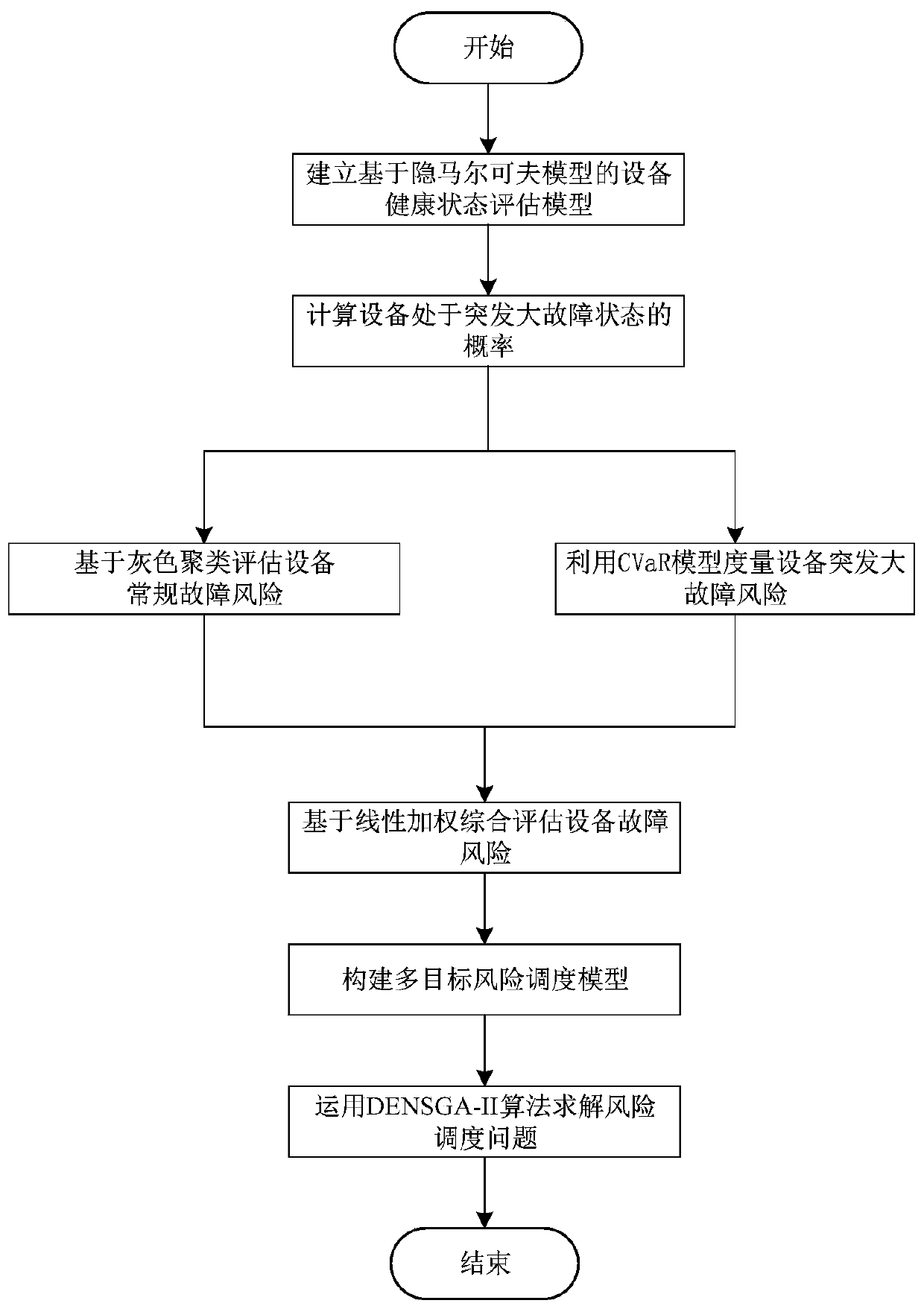

[0065] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

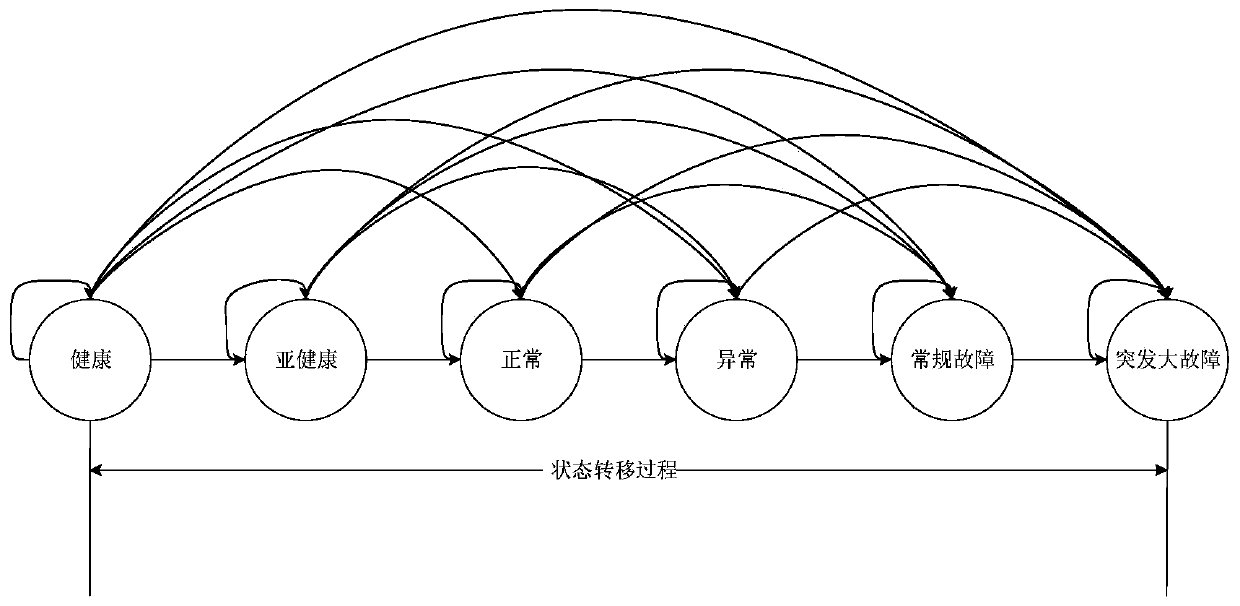

[0066] The invention discloses a production line risk dispatching method for sudden and large equipment failures, such as figure 1 As shown, the health status of production line equipment includes healthy, sub-healthy, normal, abnormal, routine failure, and sudden major failure status.

[0067] step 1):

[0068] 1.1) The segmented K-means method is used to initialize the model parameters, and the hidden Markov model initialization parameter λ is obtained by continuously iterating the model cluster centers, that is, λ=(π, A, B).

[0069] In the formula, π represents the initial state distribution vector, A represents the state transition probability distribution matrix, and B represents the observation value probability matrix.

[0070] 1.2) Input the tracking data of the performance parameters of the production line equipment, train the model par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com