Cam actuated switch module and manufacturing method thereof

A switch module and actuating switch technology, applied in the direction of electric switches, contact drive mechanisms, electrical components, etc., can solve the problems of increasing power, increasing power loss, increasing raw material usage, etc., to reduce size and reduce power loss , the effect of large space optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

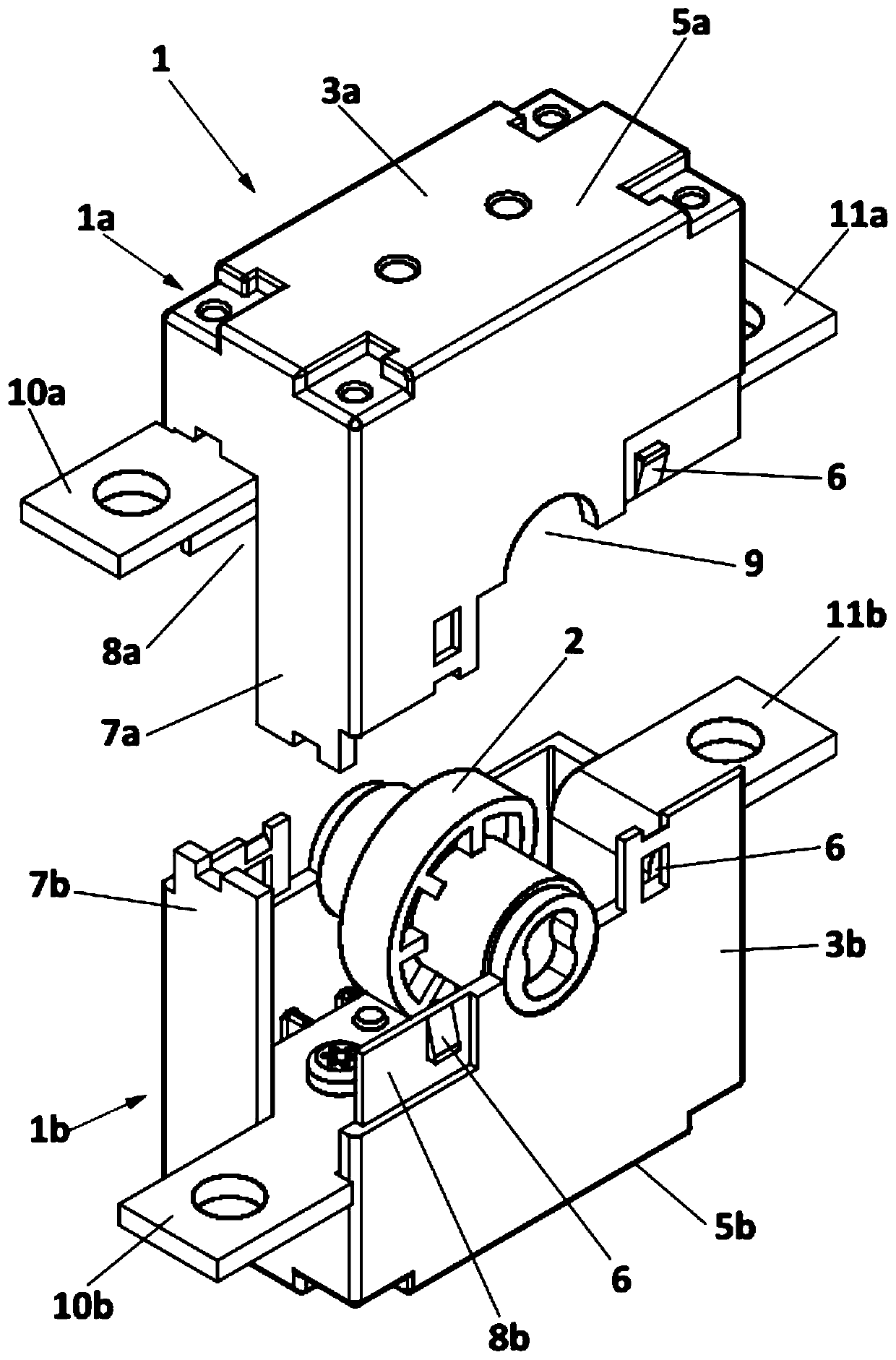

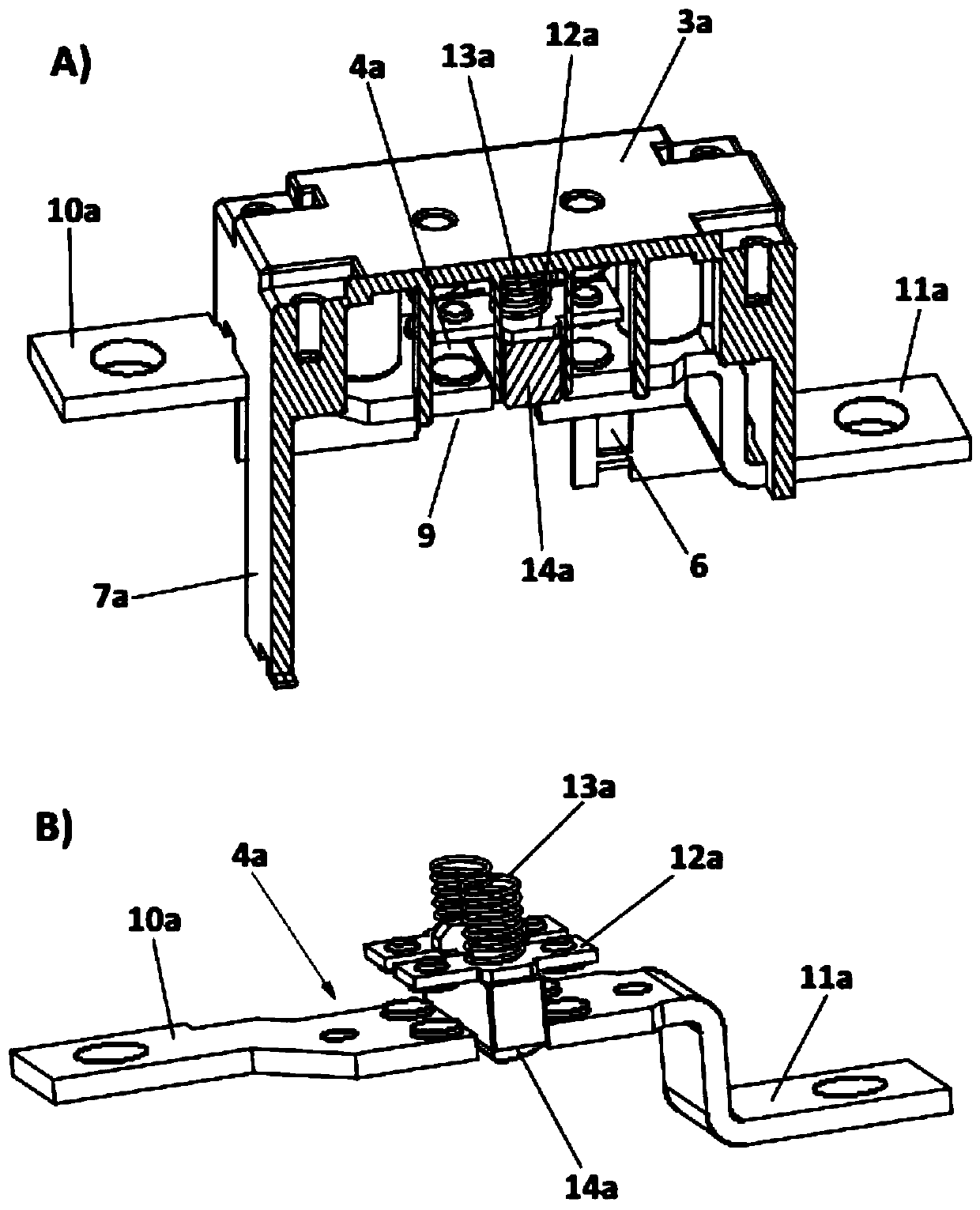

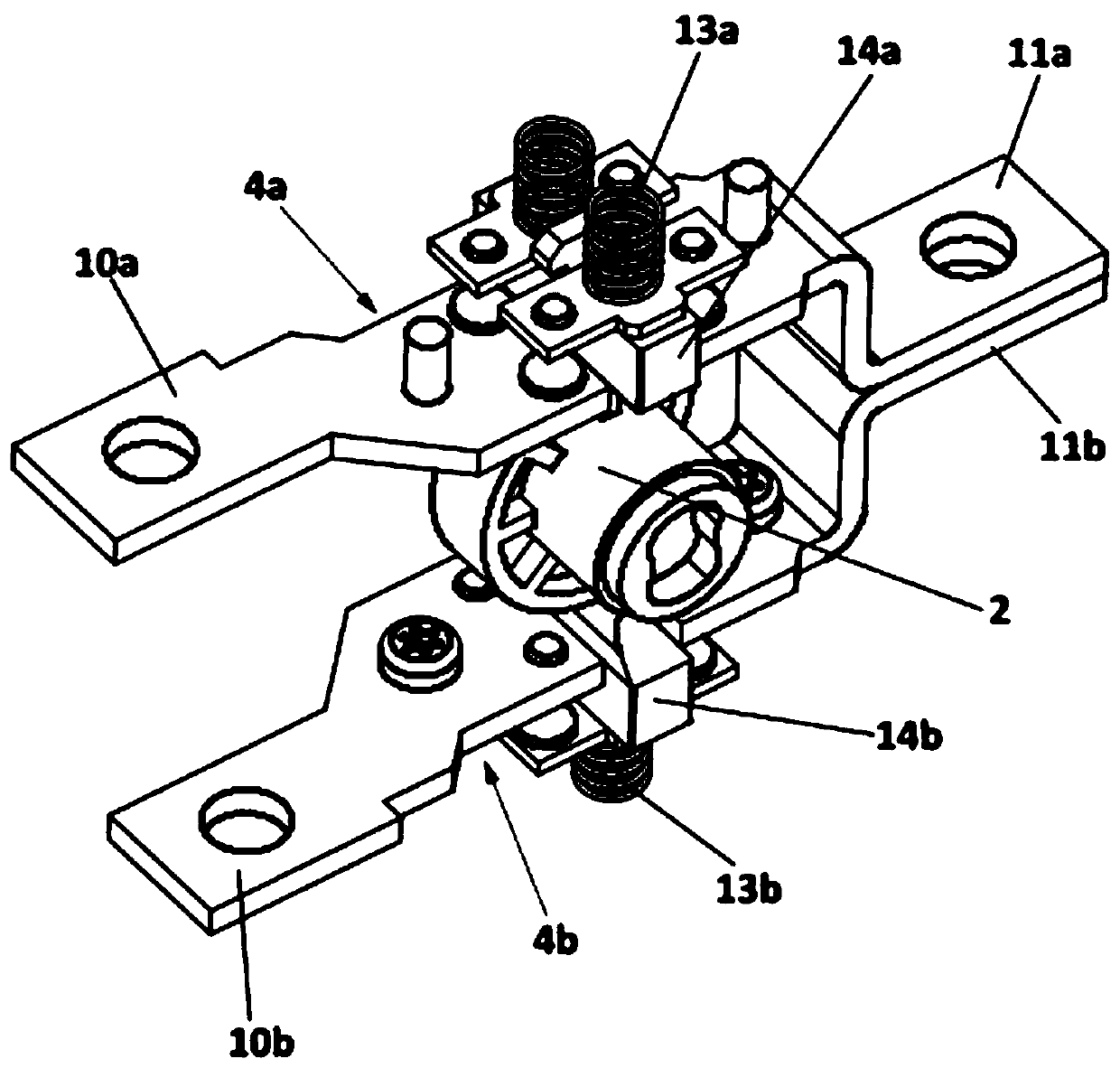

[0039] Such as figure 1 As shown in the example shown, the switch module 1 of the present invention consists of two identical half-modules (1a, 1b) connected to each other and by the two half-modules (1a, 1b) held when they are assembled Rotary cam (2) constitutes.

[0040] Both the first module (1a) and the second half-module (1b) comprise two identical half-shells (3a, 3b), and two identical switches (4a, 4b), the switches (4a, 4b) are respectively mounted on The interior of the half shells (3a, 3b). The half-shells (3a, 3b) are made of moldable and electrically insulating material, since they are molded in the same mould, they are identical in structure.

[0041] The first half-shell (3a) and the second half-shell (3b) have two semicircular cutouts (9) which define a circular opening (15), for example when the two half-shells are assembled, The cylindrical part of the cam (2) can be accommodated in the opening (15) and can be rotated and guided in the opening (15).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com