Circuit board based on fault discontinuous meshes and preparation process of circuit board

A technology for circuit boards and substrates, applied in the field of circuit boards based on fault-discontinuous meshes and its preparation process, can solve problems such as difficult to ensure the effective formation of partition layers and generation of bubbles, and achieve the elimination of transmission loss, accelerated fading, The effect of improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

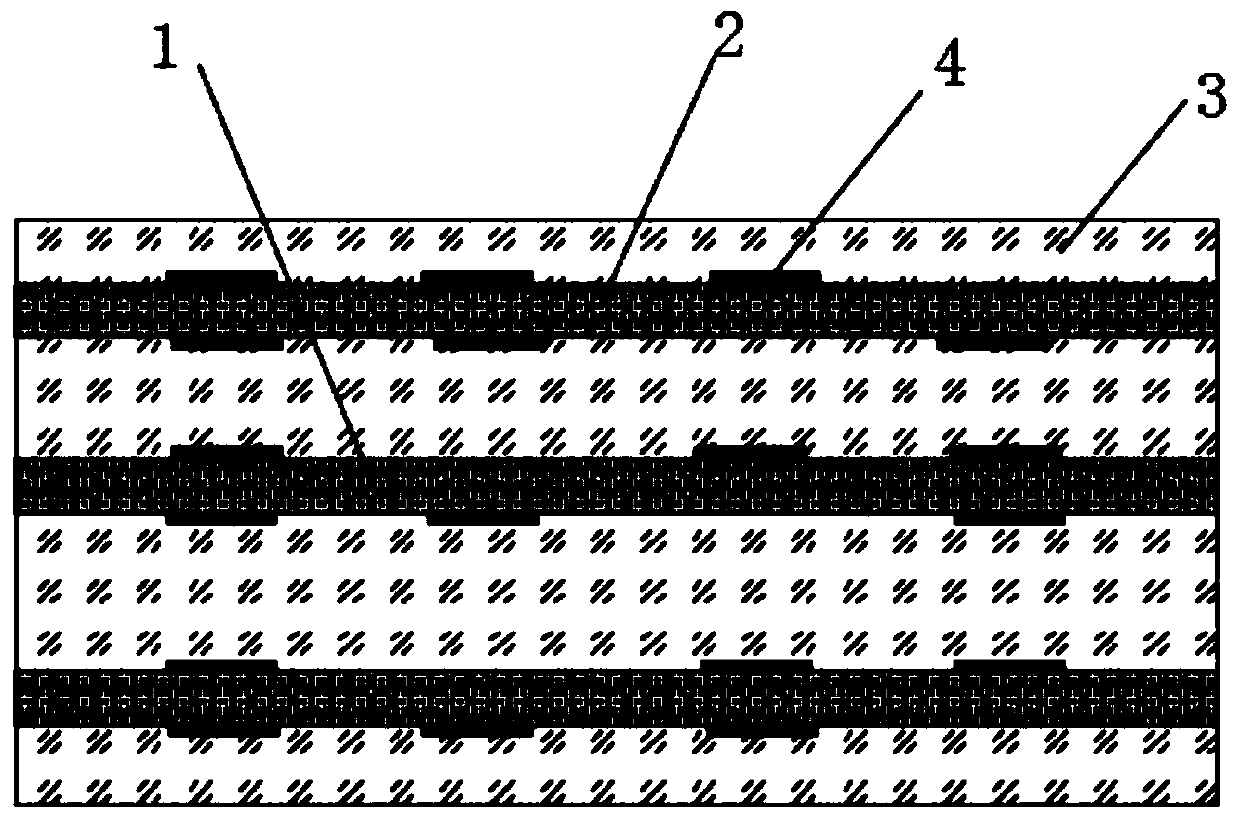

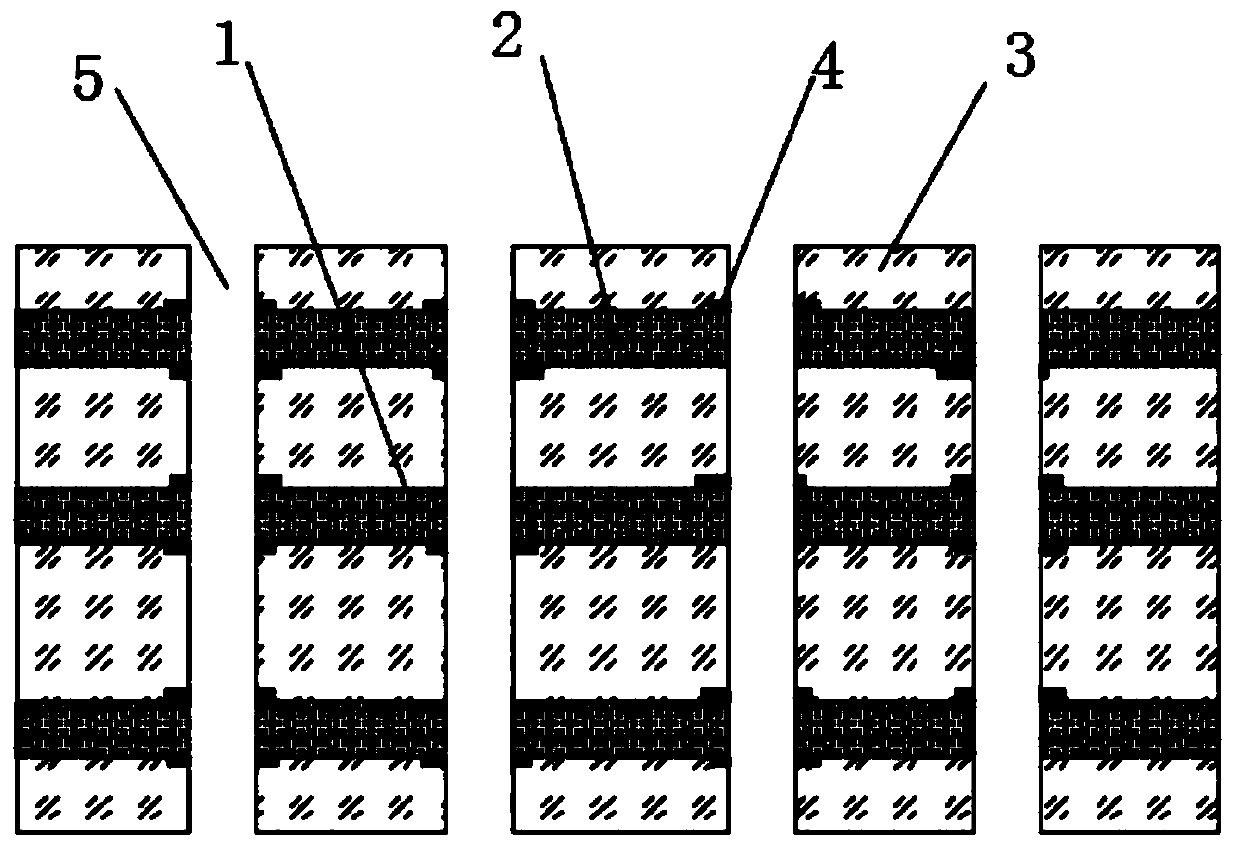

[0046] see figure 2 , a circuit board based on a fault-discontinuous mesh, including a first substrate 1 and a second substrate 2, the second substrate 2 is located on the upper side of the first substrate 1, and the second substrate 2 is connected to the first substrate 1 There is a connection piece 3, and the end of the second substrate 2 away from the first substrate 1 is also connected to the connection piece 3, and the connection between the first substrate 1 and the second substrate 2 and the connection piece 3 is connected with a plating resist 4, please refer to image 3 , the first substrate 1, the second substrate 2 and the connecting sheet 3 are correspondingly drilled with a plurality of through holes 5, please refer to Figure 4 , and the through hole 5 is located at the position of the plating resist layer 4 to set up the isolation layer region 6 .

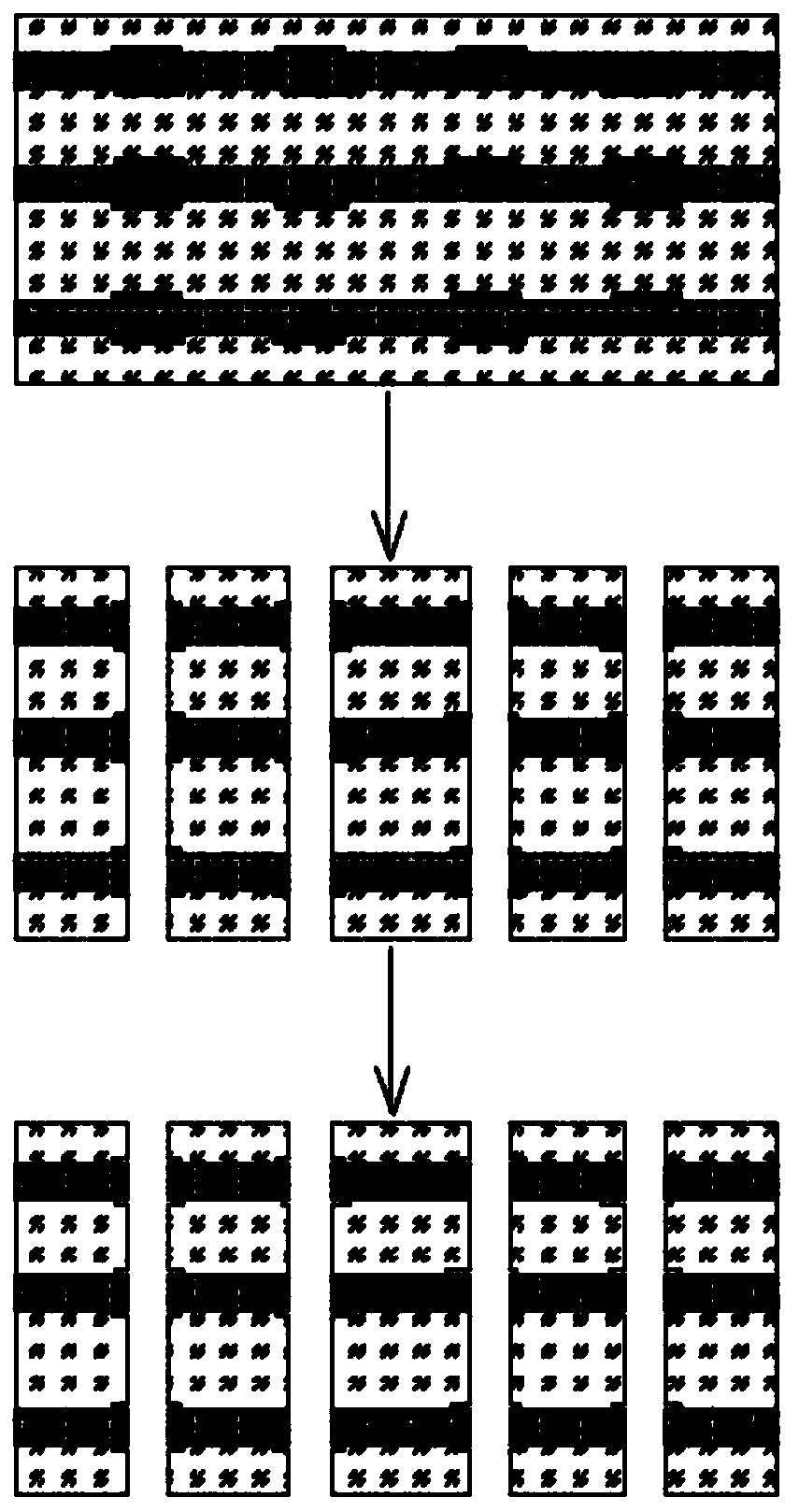

[0047] see figure 1 , a circuit board based on fault discontinuous mesh, its preparation process is:

[0048] ...

Embodiment 2

[0063] see figure 2 , a circuit board based on a fault-discontinuous mesh, including a first substrate 1 and a second substrate 2, the second substrate 2 is located on the upper side of the first substrate 1, and the second substrate 2 is connected to the first substrate 1 There is a connection piece 3, and the end of the second substrate 2 away from the first substrate 1 is also connected to the connection piece 3, and the connection between the first substrate 1 and the second substrate 2 and the connection piece 3 is connected with a plating resist 4, please refer to image 3 , the first substrate 1, the second substrate 2 and the connecting sheet 3 are correspondingly drilled with a plurality of through holes 5, please refer to Figure 4 , and the through hole 5 is located at the position of the plating resist layer 4 to set up the isolation layer region 6 .

[0064] see figure 1 , a circuit board based on fault discontinuous mesh, its preparation process is:

[0065] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com