Fischer-tropsch synthesis wax residue processing method and processing system

A Fischer-Tropsch synthetic wax and slag treatment technology, which is applied to chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of low economic benefit and waste of organic matter, so as to improve economic benefit, reduce pollution, extract The effect of high separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

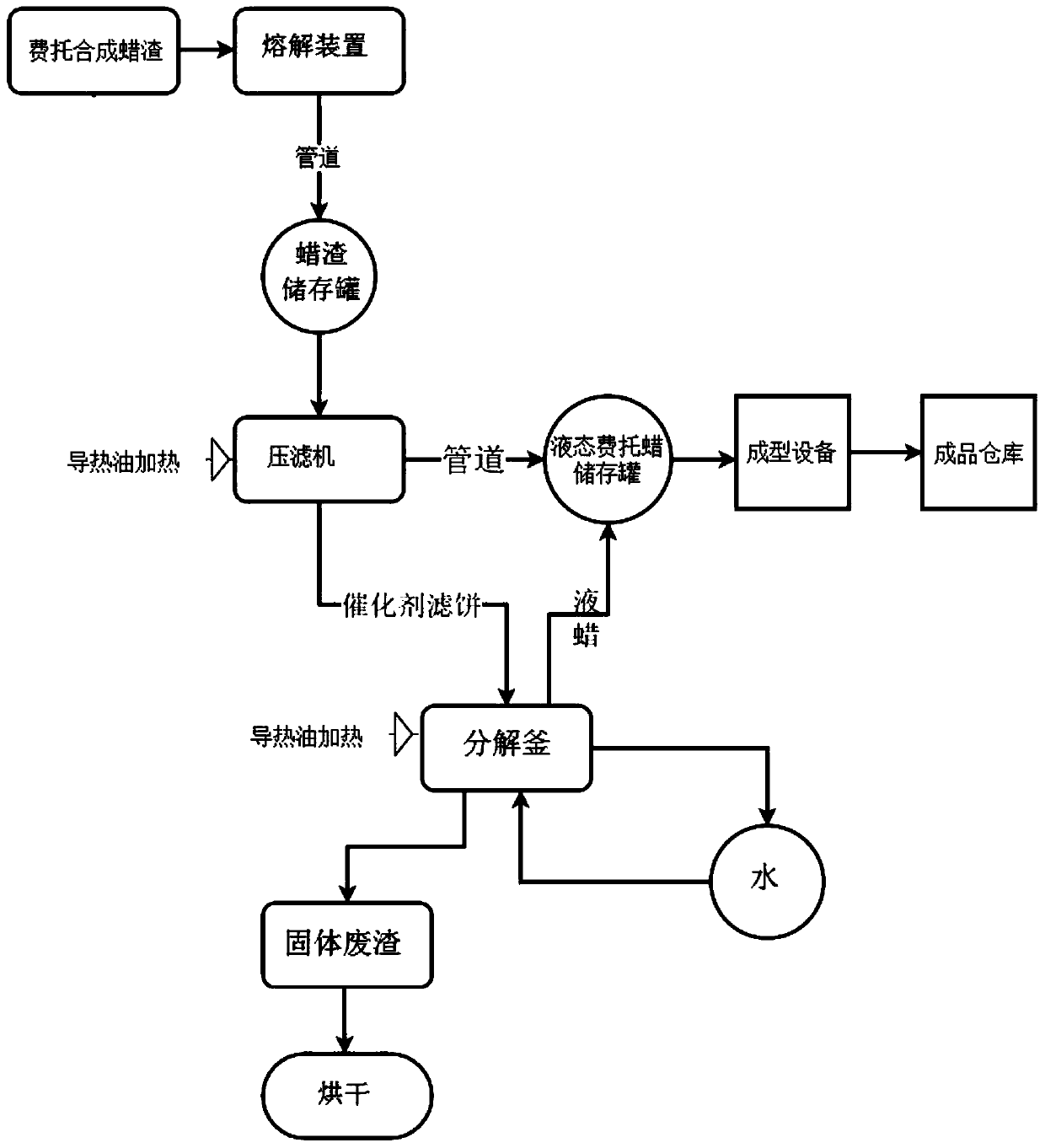

[0020] The invention provides a Fischer-Tropsch synthetic wax slag treatment method and treatment system, such as figure 1 As shown in the system, the system can quickly extract wax, is easy to operate, low in energy consumption, has no secondary pollution, and can be recycled.

[0021] Such as figure 1 The shown processing system includes a wax slag storage tank, a melting device, a filter press and a decomposition kettle, and the filter press and the decomposition kettle are respectively connected to the liquid Fischer-Tropsch wax storage tank through pipelines.

[0022] The filter press and the decomposition kettle are respectively provided with heat conduction oil circulation channels. Since the ordinary filter press does not have a heating function, the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com