A metal additive manufacturing system

A manufacturing system and metal additive technology, applied in the field of metal additive manufacturing, can solve the problems of long working time, waste of working time, and long time required for printing products, shorten the time for filling protective gas, improve printing work efficiency, The effect of reducing the measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

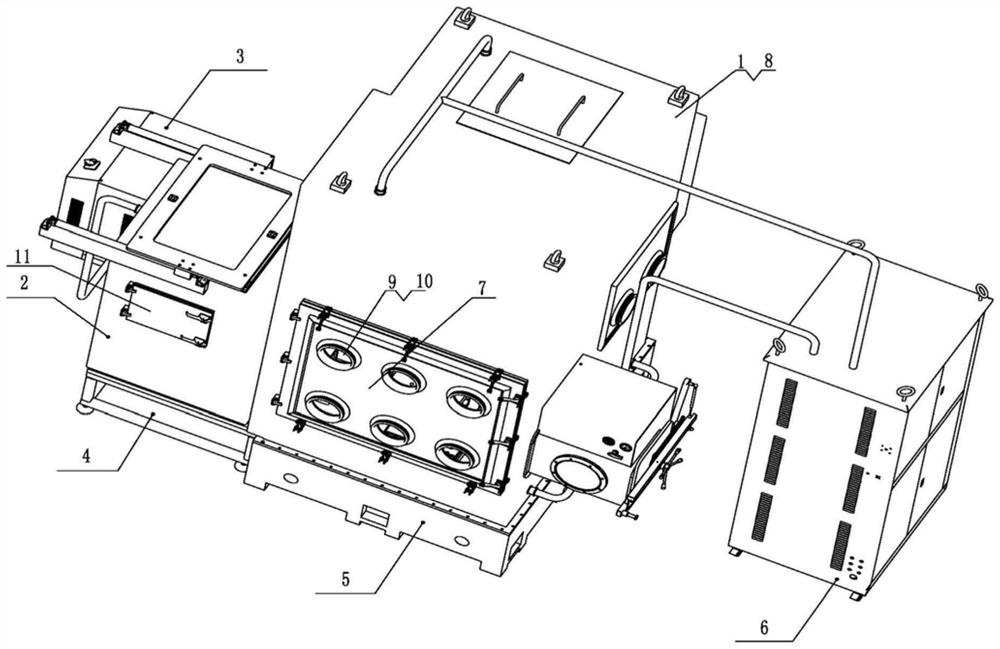

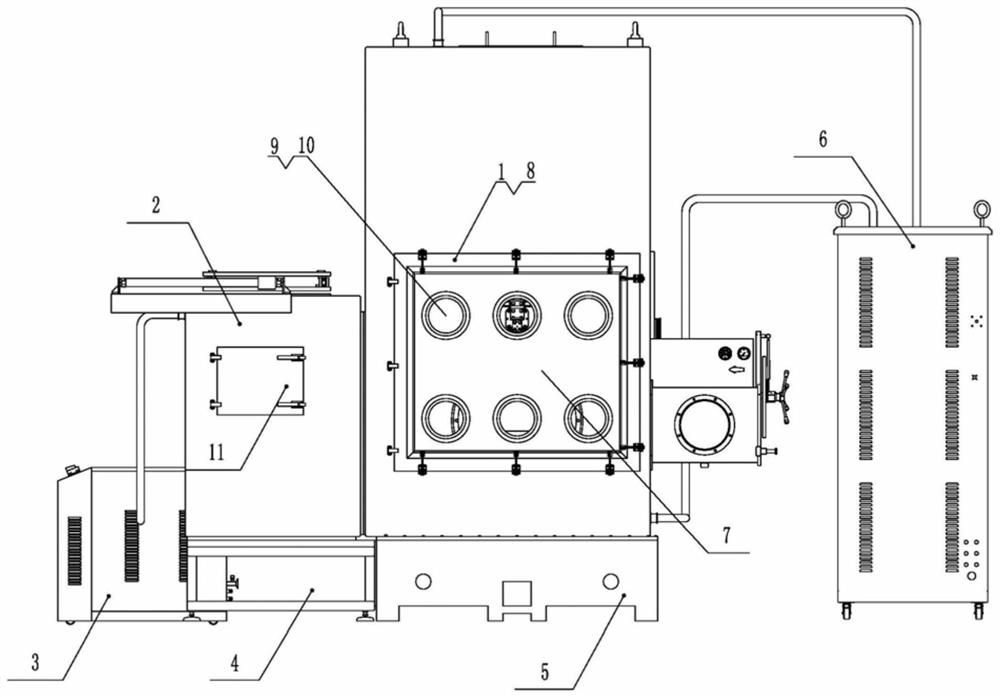

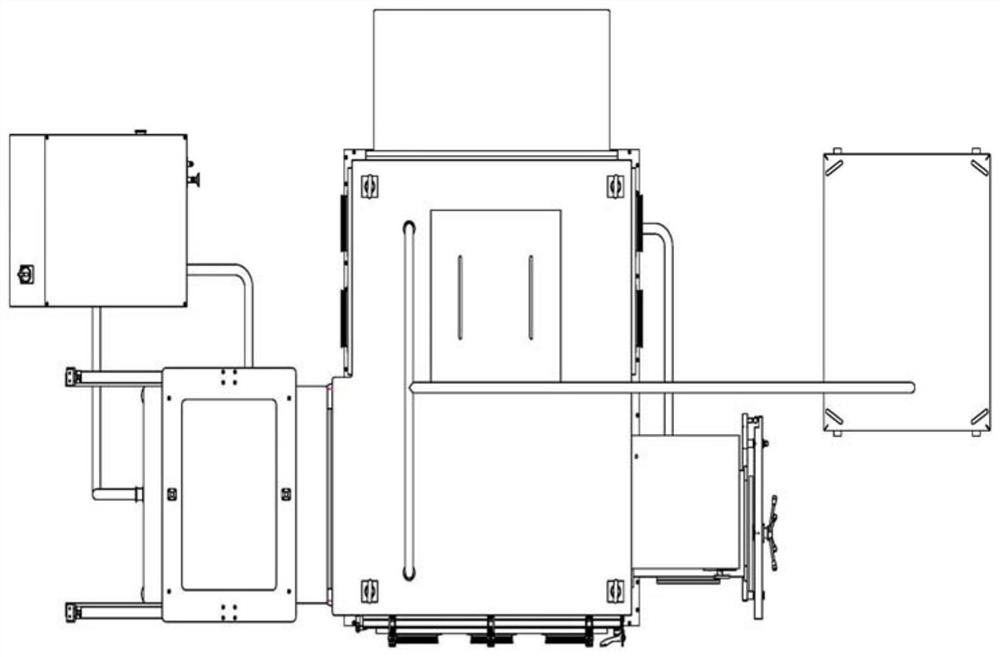

[0123] Figure 1 to Figure 4 The basic structure of the metal additive manufacturing system is given:

[0124] The system includes an equipment sealing box 1, a workpiece buffering area sealing box 2, a buffering area purifier 3, a buffering area base 4, a first airtight door assembly, an equipment base 5, an equipment purifier 6, and an additive equipment 8;

[0125] The bottom of the equipment sealing box 1 is fixedly installed on the equipment base 5, and a sealing ring is installed between the bottom surface of the equipment sealing box 1 and the top surface of the equipment base 5; the buffer area base 4 is installed on the left side of the equipment base 5, and the workpiece buffer area sealing box 2 is fixed Installed on the base 4 of the buffer area and a sealing ring is installed between the bottom surface of the sealing box 2 of the workpiece buffer area and the top surface of the base 4 of the buffer area; a first sealing door assembly is arranged between the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com