Hydraulic cutter changing system of machining center

A hydraulic and cushioning hydraulic cylinder technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of high gas compressibility, large noise, poor working stability, etc., and achieve high repeat positioning accuracy , rapid tool change and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

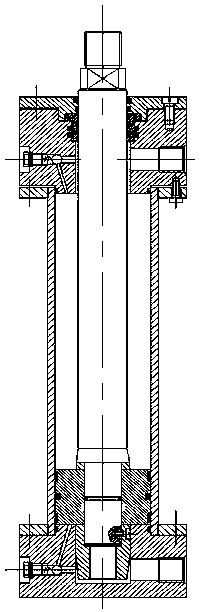

[0023] The present invention will be further described below in conjunction with specific examples.

[0024] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

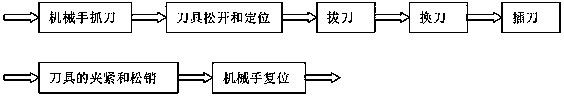

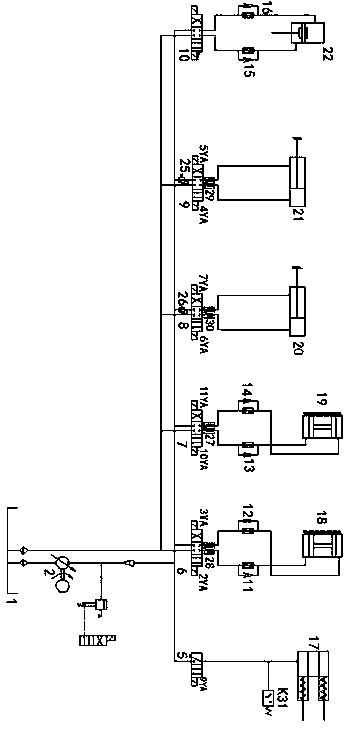

[0025] The application principle of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Generally speaking, there are two schemes for the tool changer of the manipulator in the machining center: the first scheme is to use hydraulic drive and special structure cylindrical camshaft and knife arm guide sleeve. The second scheme is to use hydraulic drive and various types of cylinders to realize different actions of the manipulator....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com