A pretreatment equipment suitable for ethanol fermentation of food waste

A technology for ethanol fermentation and kitchen waste, which is applied in the fields of biomass pretreatment, biochemical equipment and methods, biochemical instruments, etc., can solve problems such as energy waste, achieve high efficiency, compact structure, and meet the needs of separation and treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

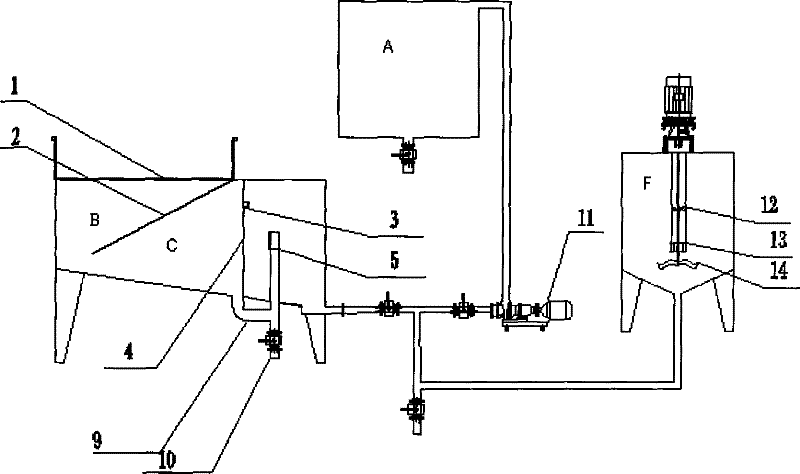

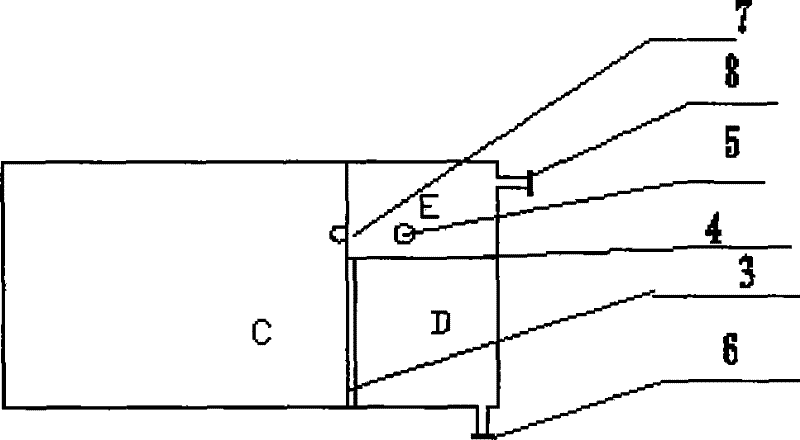

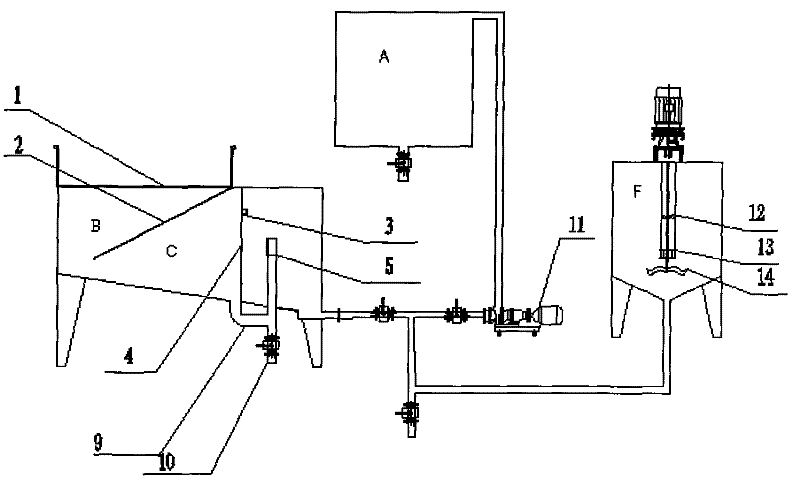

[0019] The present invention will be further described in conjunction with accompanying drawings.

[0020] Depend on figure 1 , figure 2 As shown, the pretreatment equipment includes an oil-water separation device, a feed liquid storage tank, and a homogenization device. The food waste first passes through the solid separation sieve 1. Since the separation sieve has a relatively large area, it is beneficial to spread the waste, and materials that are not suitable for fermentation can be manually selected, such as ironware, plastic bags, and large bone sticks mixed in the waste. etc. The sieved garbage falls to the deflector 2, and the deflector divides the separation device into two parts, the upper part is the diversion chamber B, and the lower part is the separation chamber C. The deflector 2 is placed at an angle of 45 degrees to the horizontal plane so that the sieved garbage can reach the diversion chamber B smoothly. The garbage coming in from the chamber enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com