Liquid ring vacuum pump for degassing plastic melts

A technology of liquid ring vacuum pump and molten liquid, which is applied in the direction of pumps, rotary piston pumps, machines/engines, etc., and can solve the problems that continuous operation cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

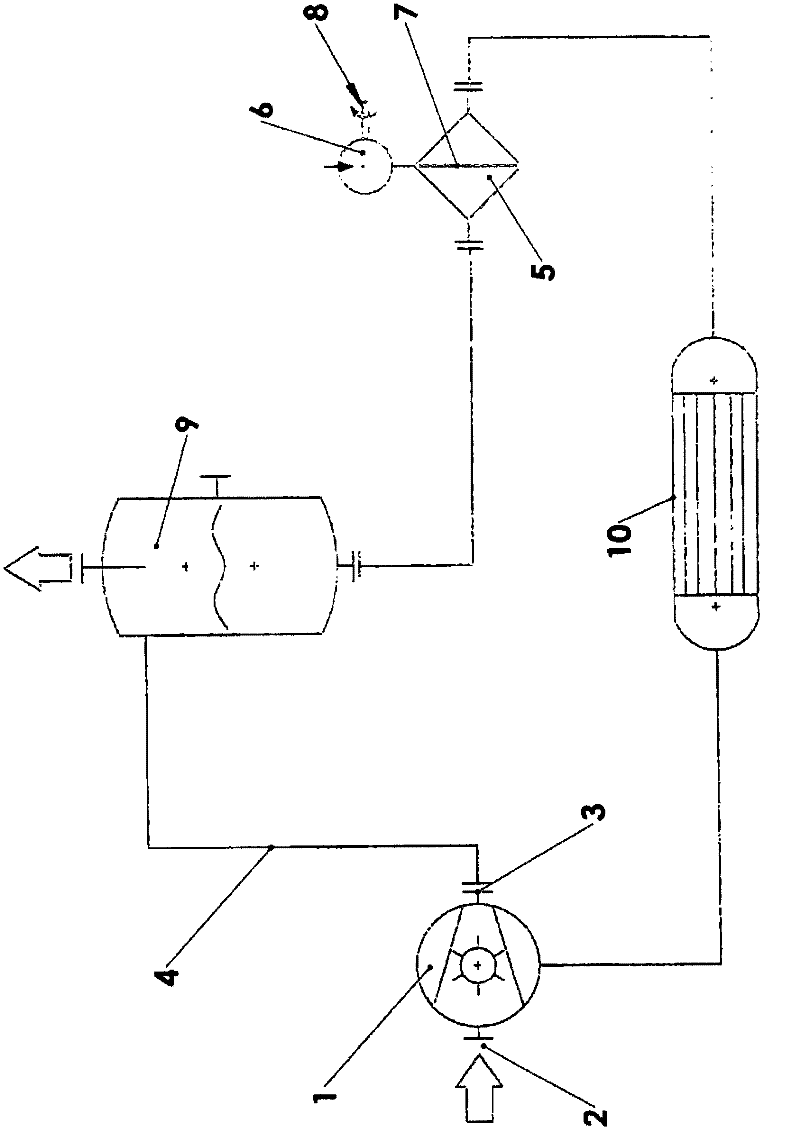

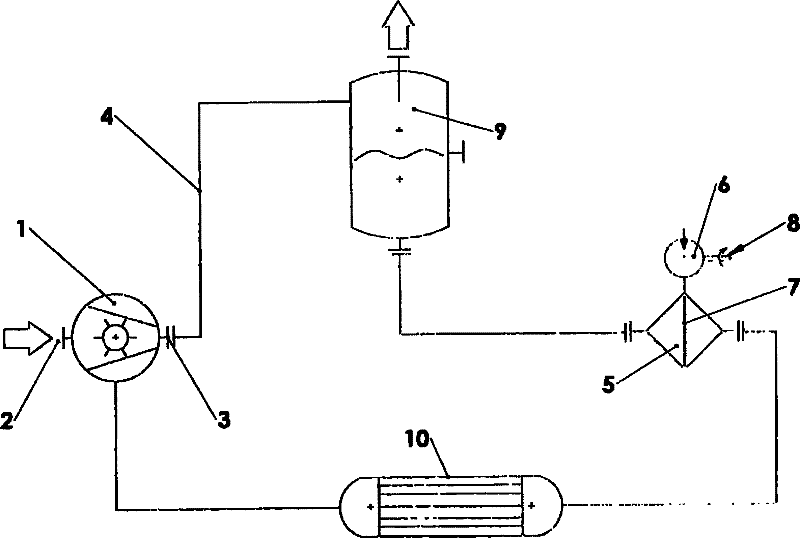

[0018] The present invention is further described according to the accompanying drawings. In this case, the drawing shows a liquid ring vacuum pump 1 with a pump inlet 2 and a pump outlet 3 . The liquid ring vacuum pump 1 is integrated into a circuit 4 in which the compressed liquid is purged. The circuit 4 has a continuously operating filter 5 , the motor 6 of which replaces the filter element 7 depending on the contamination of the filter element via the indicated adjustment device 8 .

[0019] The pump outlet 3 is also formed as a connection to the circuit 4 at the same time. In the liquid separator 9 the exhaust gas is separated from the compressed liquid, from which the compressed liquid reaches the continuously working filter 5 . Furthermore, a cooling device 10 is provided, by means of which the compressed liquid is brought to the desired level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com