Sliding bearing

A technology of sliding bearings and virtual circles, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as difficulty in removing impurities and waste, severe wear, and small contact surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings.

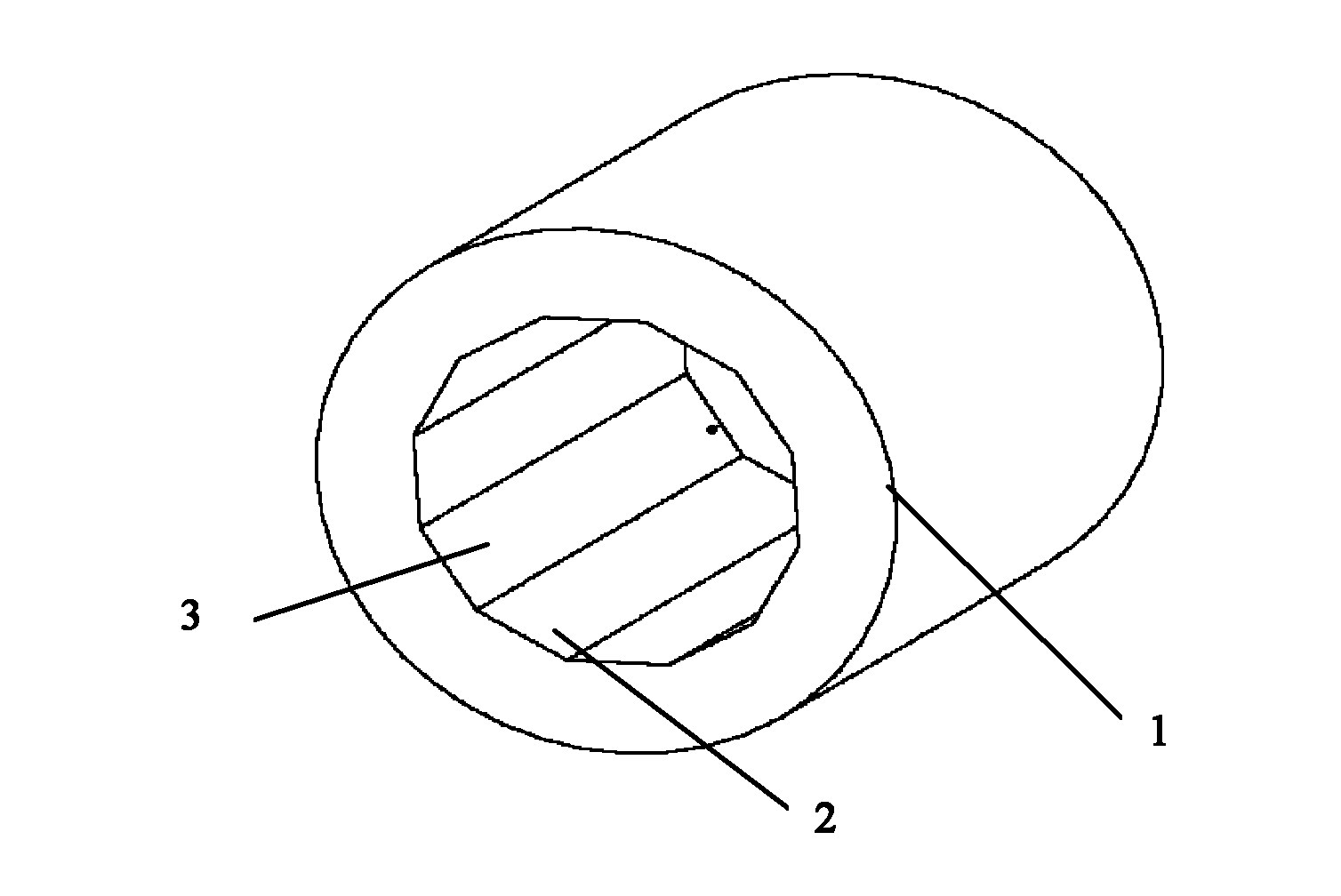

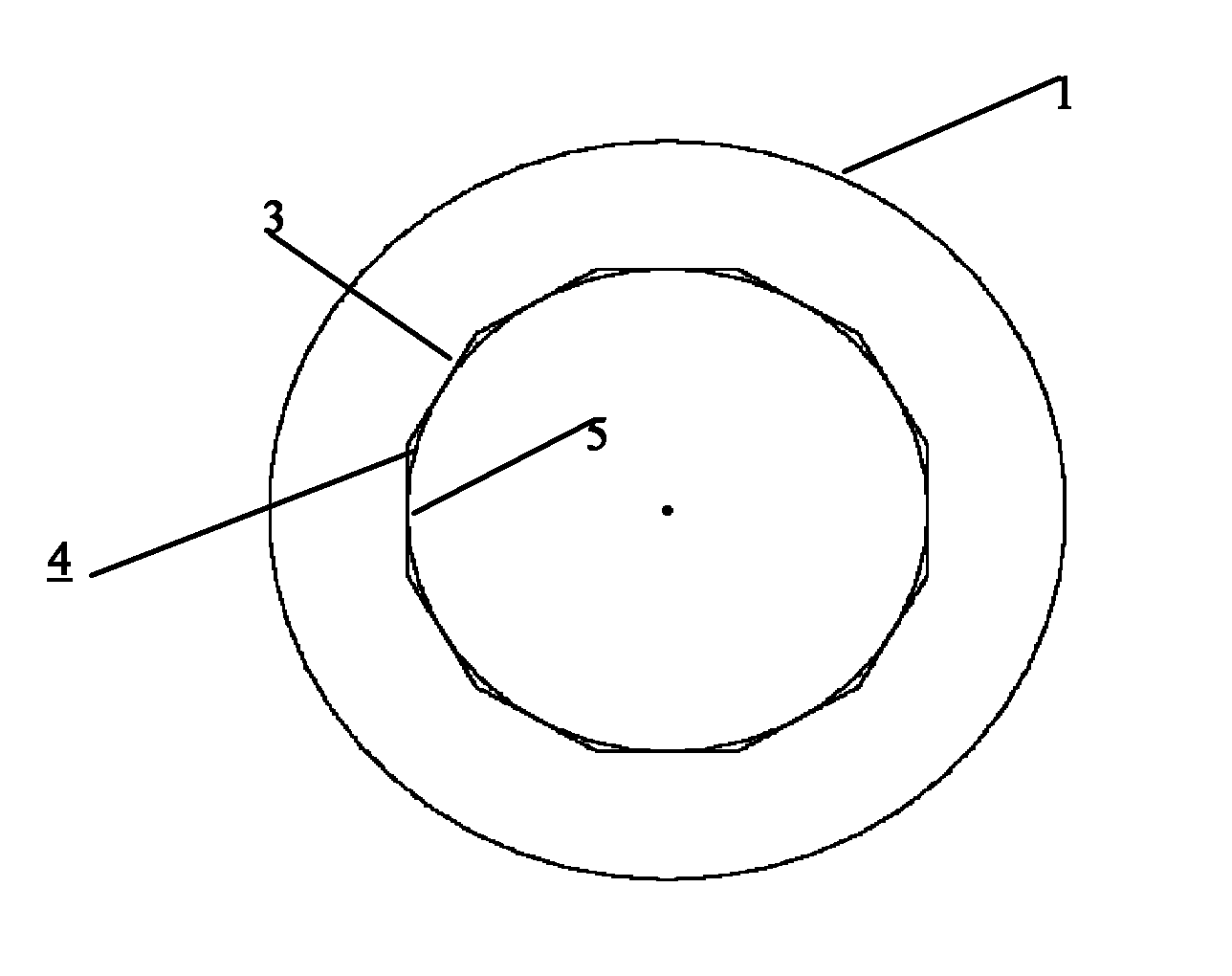

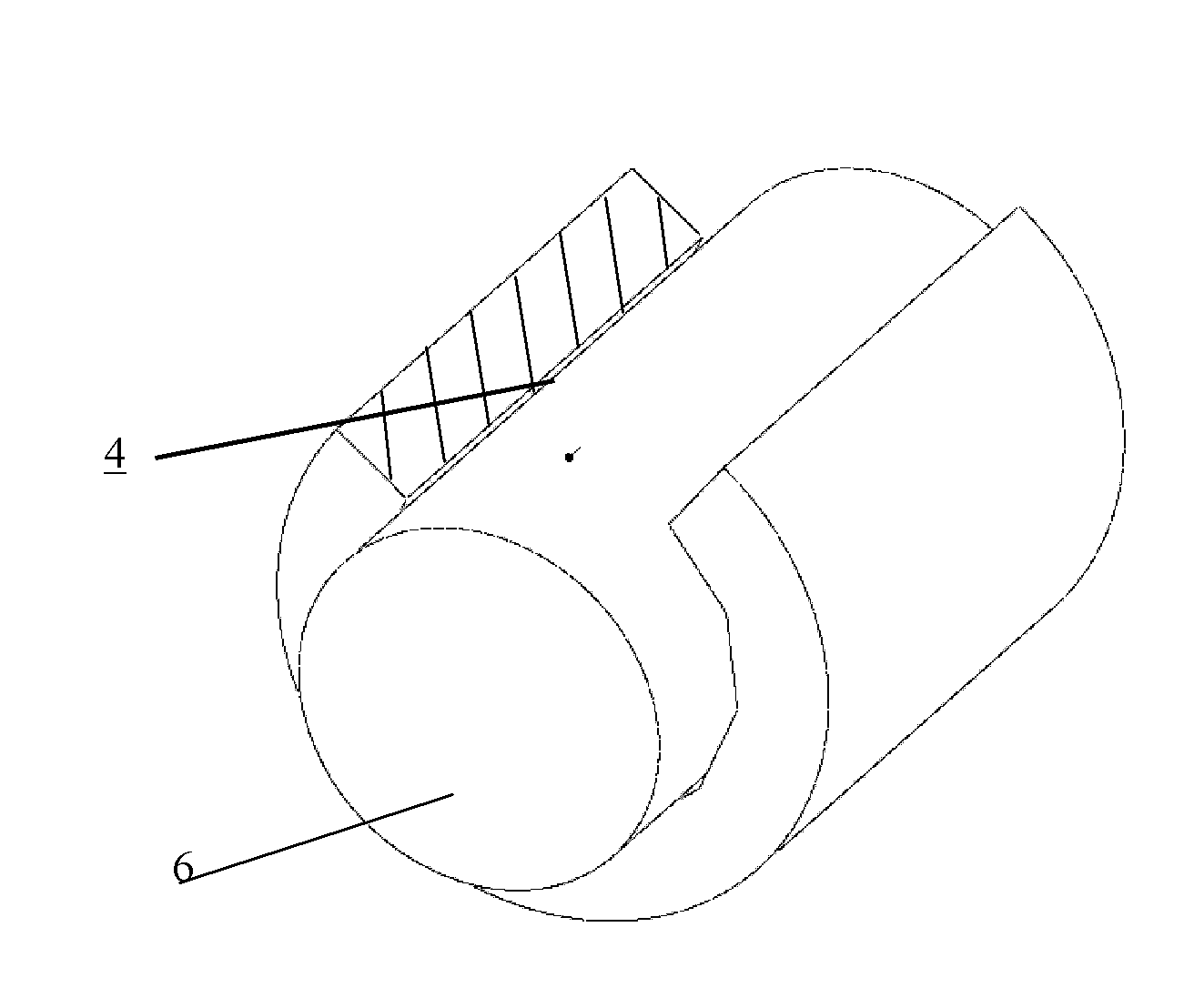

[0022] Such as Figure 1-6 As shown, the sliding bearing of the present invention includes an outer ring 1 and an inner ring 2, as shown in a cross-sectional schematic diagram thereof, wherein the outer ring 1 is formed by a standard circle with a diameter D, and the inner ring 2 of the sliding bearing is a regular polygon. A closed circle formed by connecting four arcs 3 with the same radius R and the same arc length L, and each arc is circumscribed with a virtual circle 5 with a diameter d whose center is the center of the outer circle D. The diameter of the circle 5 is equivalent to the diameter of the shaft 6, equal to or slightly larger than the diameter of the shaft 6, and each point of tangency divides the virtual circle with a diameter d equally. Meanwhile, the radius R of the arc 3 can be any value greater than d / 2 to infinity. The sliding b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com