Loudspeaker assembling tool and working method thereof

A technology for assembling tooling and ring points, which is used in manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve the problems of low positioning accuracy, low installation efficiency, high labor intensity, etc., and achieve high repeat positioning accuracy and assembly efficiency. High, low labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0055] The invention provides a click assembly tool, which can be used for click assembly with 3, more than 3 or less than 3 click points. This embodiment takes the click click with 3 click points as an example to introduce the click Affects the structure of the assembly tooling.

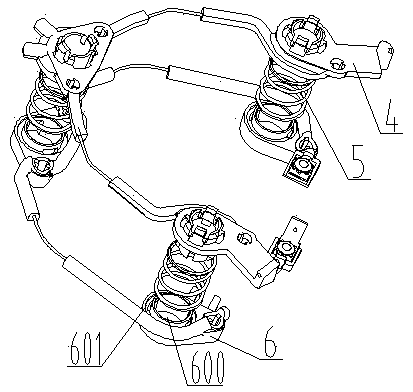

[0056] Such as figure 1 As shown, the clicker includes a lower product 4, a product spring 5 and an upper product 6, and the lower product 4 and the upper product 6 are provided with a plurality of clicking points, and the lower product 4 and the upper product 6 pass through each A group of buckles at the two click points are snapped together, and the product spring 5 is arranged between the lower product 4 and the upper product 6.

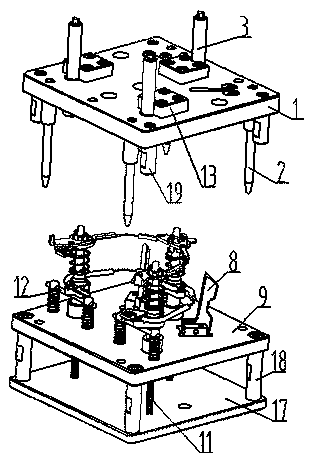

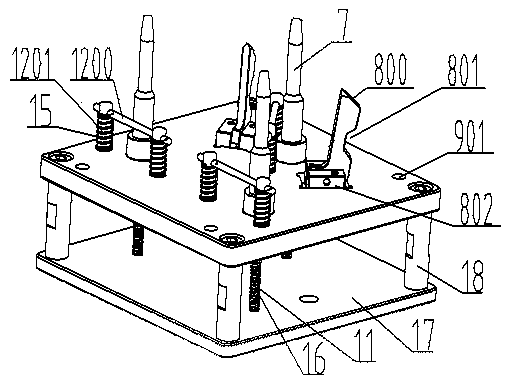

[0057] Such as figure 2 As shown, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com