A method for preparing three-dimensional hollow molybdenum sulfide based on upconversion nanoparticles

A nanoparticle, hollow structure technology, applied in the field of materials chemistry, can solve problems such as harsh synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

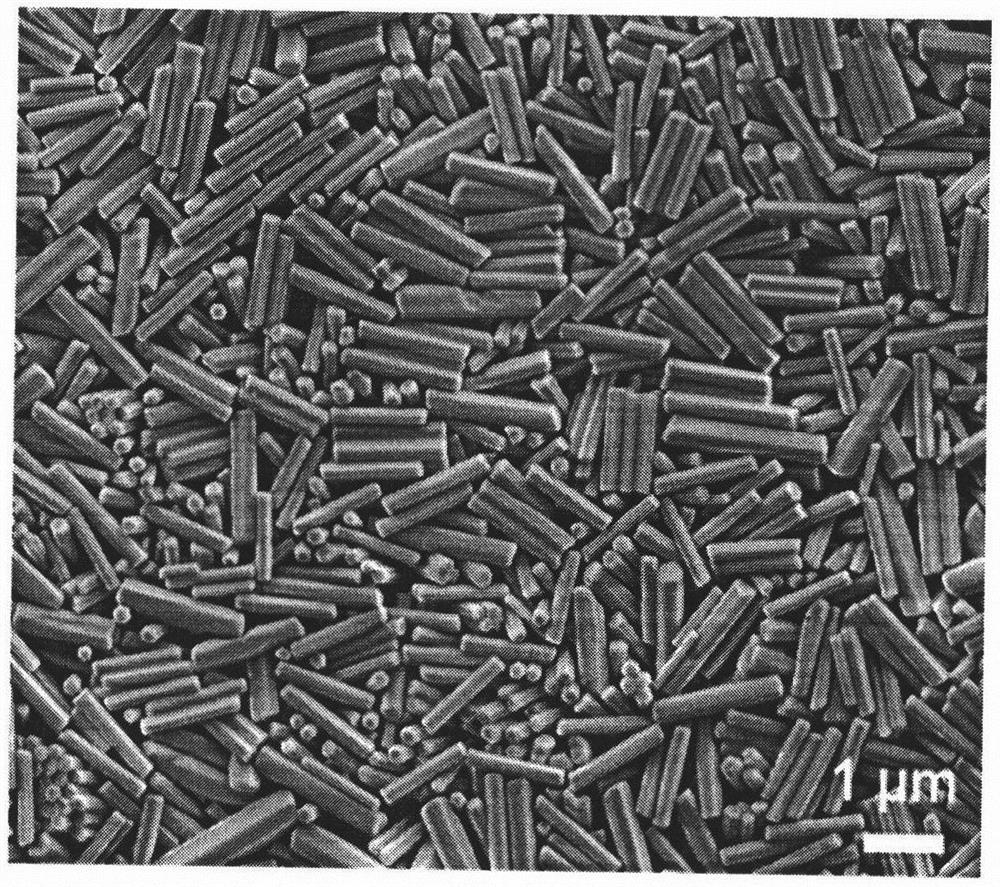

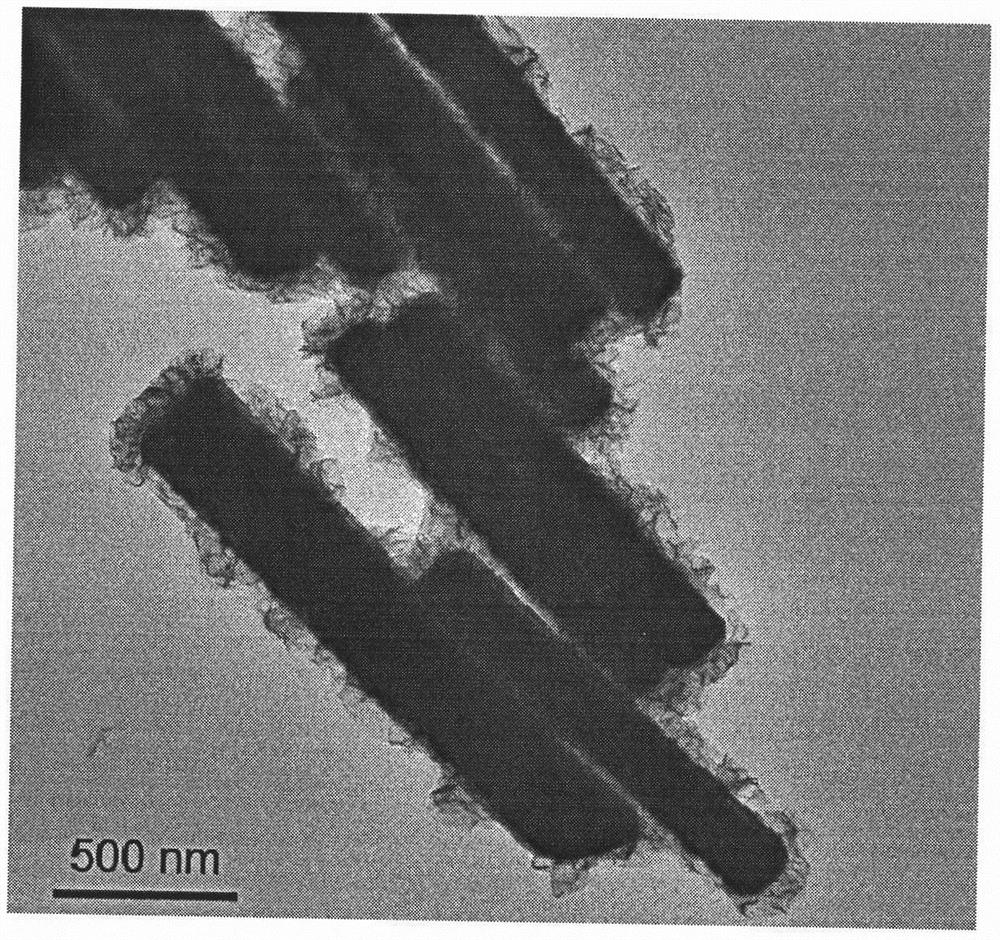

Embodiment 1

[0018] Pre-prepared 0.4mmol NaYF with a length of about 1.5μm 4 : Yb / Er microrods dispersed in 4mL ethanol, take 1mL of the above 0.1mol / L NaYF 4 : Put the ethanol solution of Yb / Er in a 2mL centrifuge tube, put it in a centrifuge and centrifuge at 12000rpm for 1min, disperse the lower sediment in 750μL ethanol for ultrasonication, after the dispersion is even, add 500μL 1mol / L dilute hydrochloric acid for 30s, put it in the centrifuge Centrifuge at 12000rpm for 15min in the machine, pour off the upper solution, disperse the lower precipitate in 750μL ethanol for ultrasonication, add 50μL 1mol / L dilute hydrochloric acid for 10s, and centrifuge at 12000rpm for 15min, and disperse the white precipitate obtained by centrifugation in 0.5mL H 2 Reserved in O. Add 1 mL of 0.2 mol / L NaYF to wash away the oleic acid ligand to 4 mL of 0.04 mmol of disodium edetate aqueous solution and 4 mL of 0.2 mmol of sodium fluoride aqueous solution 4 : The Yb / Er aqueous solution was stirred for ...

Embodiment 2

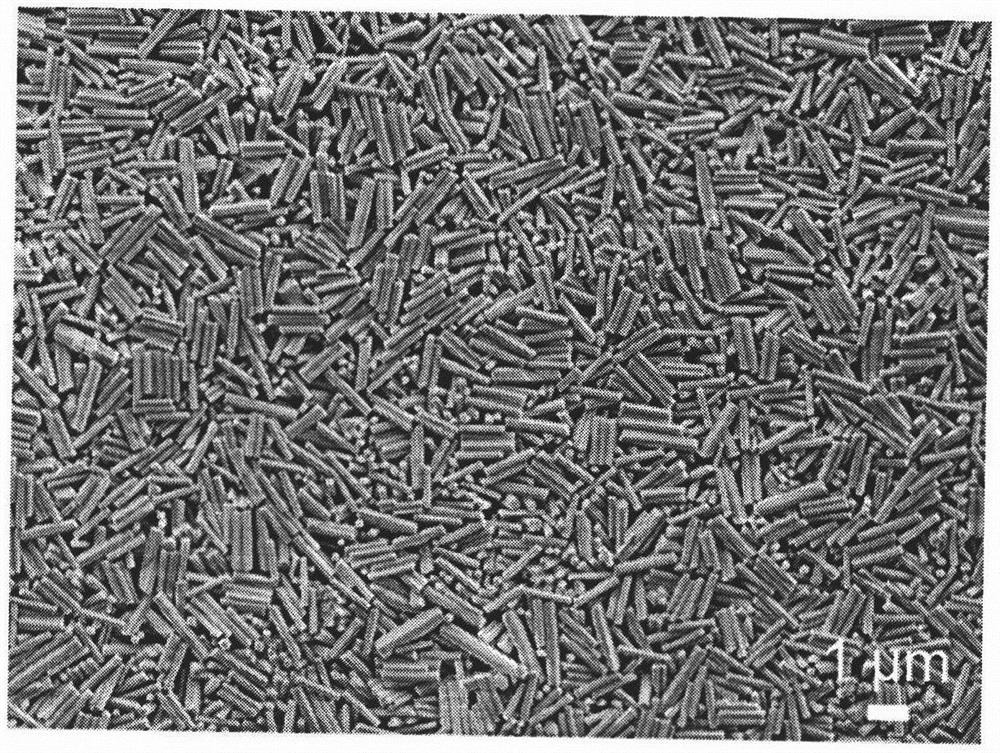

[0020] Pre-prepared 0.4mmol NaYF with a length of about 400nm 4 : Yb / Er / Gd microrods dispersed in 4mL ethanol, take 1mL above 0.1mol / L NaYF 4 : Put the ethanol solution of Yb / Er in a 2mL centrifuge tube, put it in a centrifuge and centrifuge at 12000rpm for 1min, disperse the lower sediment in 750μL ethanol for ultrasonication, after the dispersion is even, add 500μL 1mol / L dilute hydrochloric acid for 30s, put it in the centrifuge Centrifuge at 12000rpm for 15min in the machine, pour off the upper solution, disperse the lower precipitate in 750μL ethanol for ultrasonication, add 50μL 1mol / L dilute hydrochloric acid for 10s, and centrifuge at 12000rpm for 15min, and disperse the white precipitate obtained by centrifugation in 0.5mL H 2 Reserved in O. Add 1 mL of 0.2 mol / L NaYF to wash away the oleic acid ligand to 4 mL of 0.04 mmol of disodium edetate aqueous solution and 4 mL of 0.2 mmol of sodium fluoride aqueous solution 4 : The Yb / Er / Gd aqueous solution was stirred for 4...

Embodiment 3

[0022] Pre-prepared 0.4mmol NaYF with a length of about 500nm 4 : Yb / Er hexagonal prisms are dispersed in 4mL ethanol, take 1mL of the above 0.1mol / L NaYF 4 : Put the ethanol solution of Yb / Er in a 2mL centrifuge tube, put it in a centrifuge and centrifuge at 12000rpm for 1min, disperse the lower sediment in 750μL ethanol for ultrasonication, after the dispersion is even, add 500μL 1mol / L dilute hydrochloric acid for 30s, put it in the centrifuge Centrifuge at 12000rpm for 15min in the machine, pour off the upper solution, disperse the lower precipitate in 750μL ethanol for ultrasonication, add 50μL 1mol / L dilute hydrochloric acid for 10s, and centrifuge at 12000rpm for 15min, and disperse the white precipitate obtained by centrifugation in 0.5mL H 2 Reserved in O. Add 1 mL of 0.2 mol / L NaYF to wash away the oleic acid ligand to 4 mL of 0.04 mmol of disodium edetate aqueous solution and 4 mL of 0.2 mmol of sodium fluoride aqueous solution 4 : The Yb / Er aqueous solution was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com