A fast vibrating mechanism for road and bridge construction asphalt, its use method and its asphalt paver

A fast and asphalt technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of low efficiency, long time consumption, poor vibrating quality and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

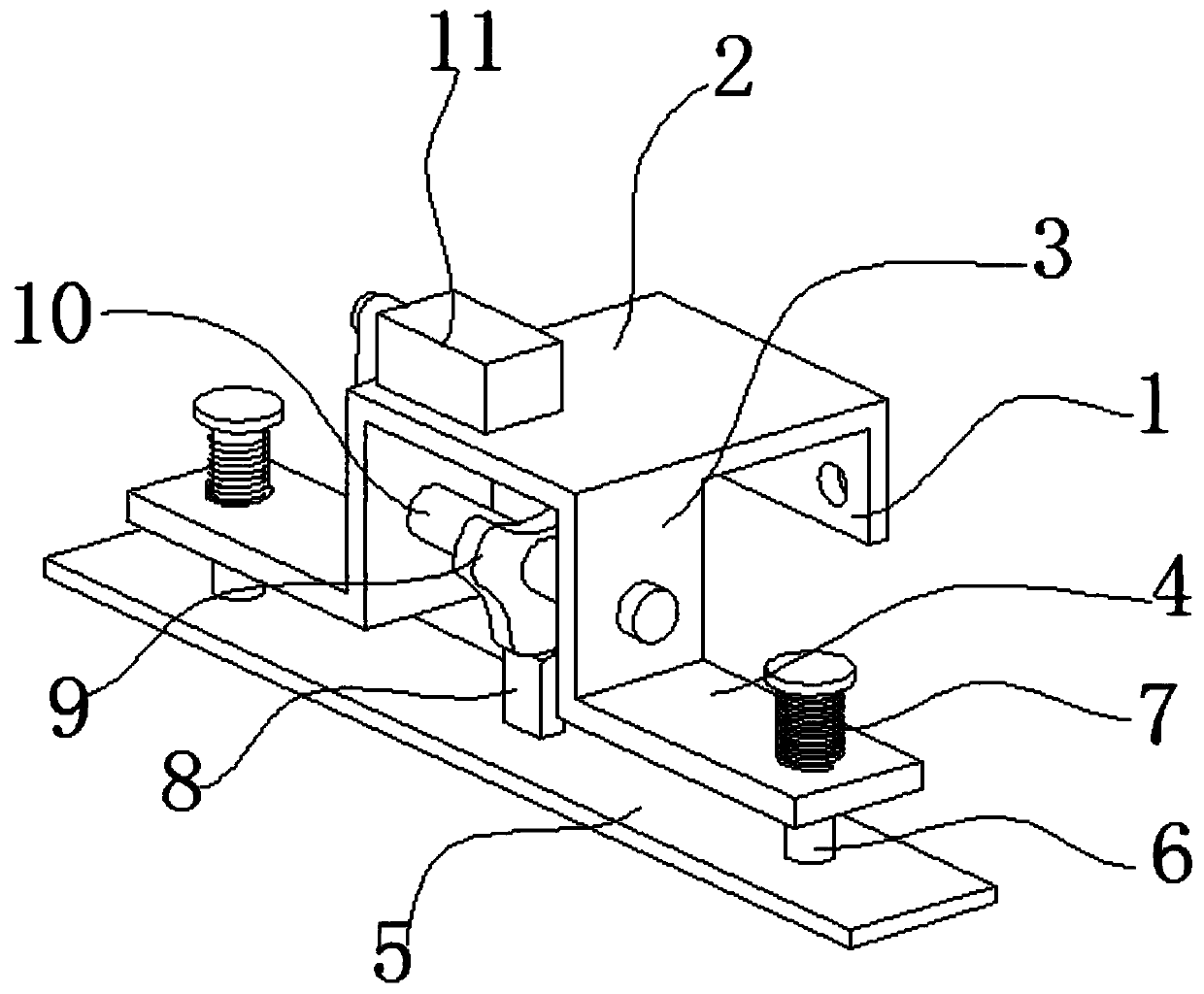

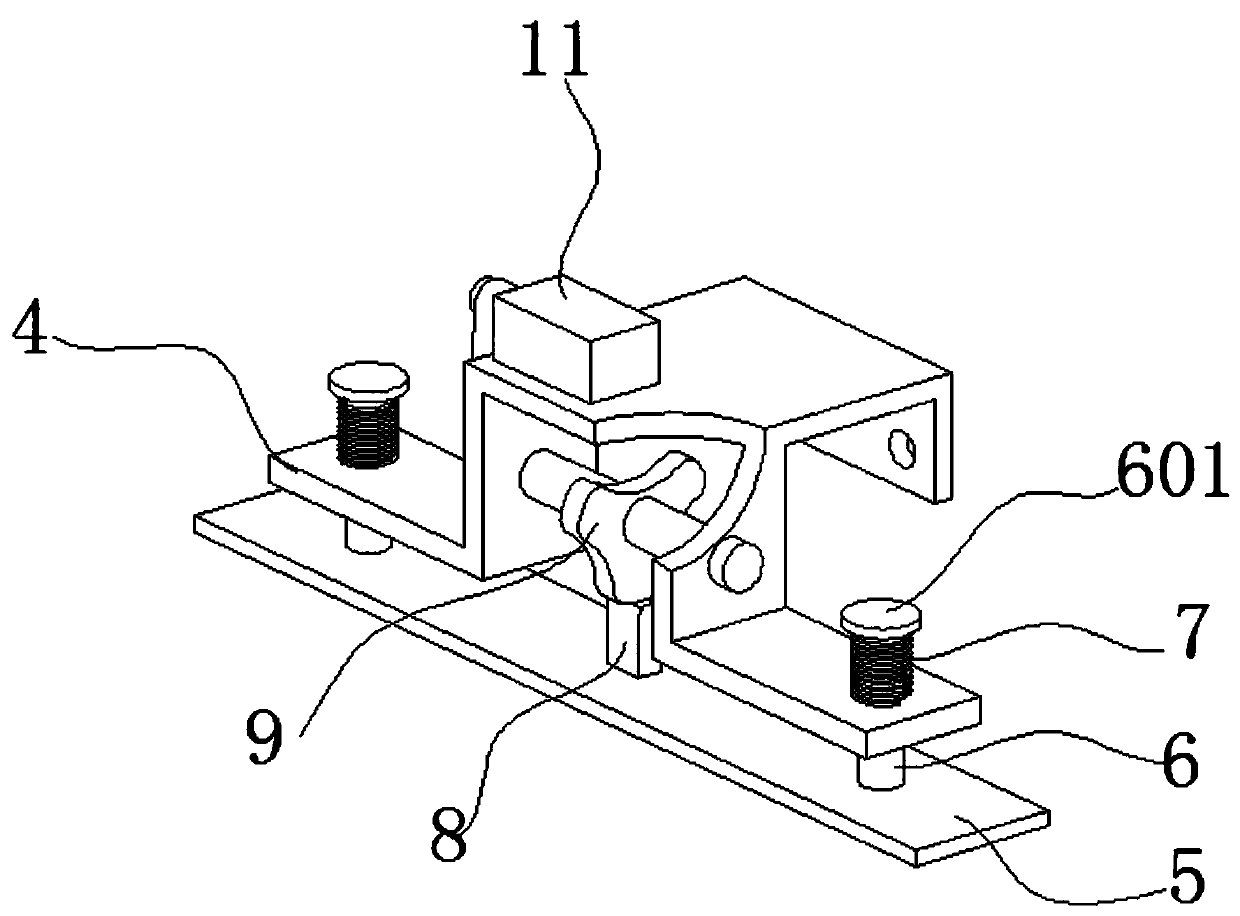

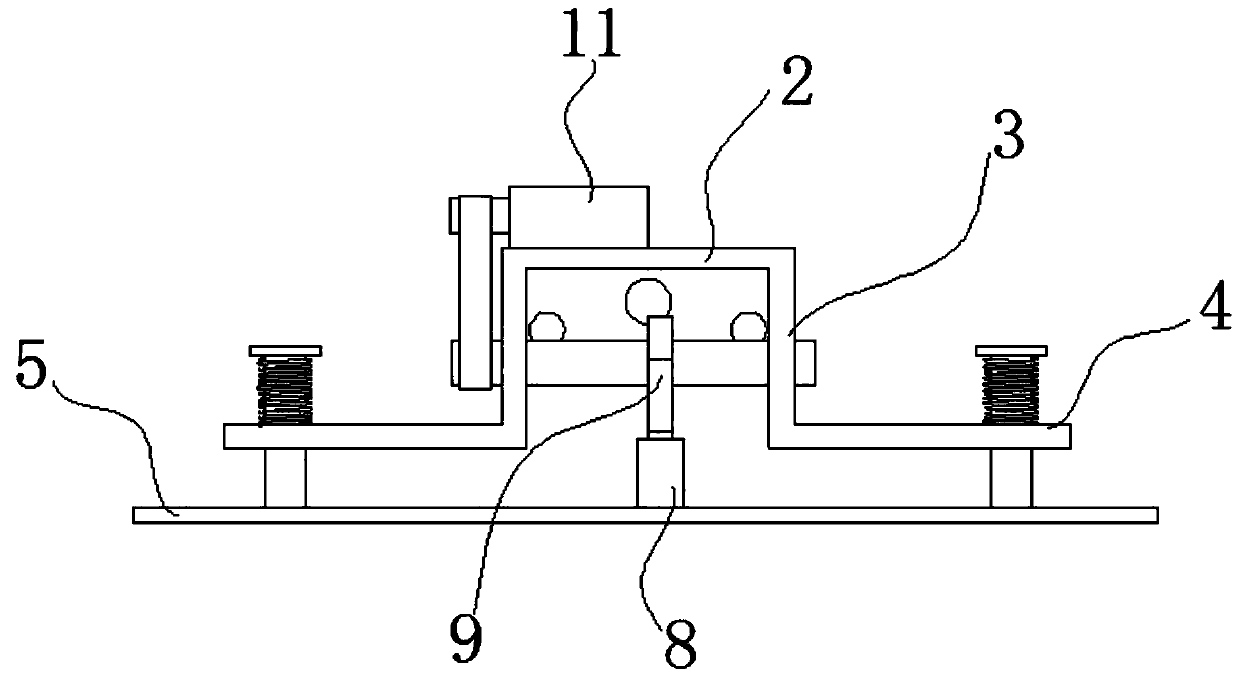

[0038] Such as figure 1 , figure 2 , image 3 with Figure 4As shown, this implementation provides a rapid vibration mechanism for road and bridge construction asphalt, including a support seat, a vibrating plate 5, a protruding rod 8 and a transmission wheel 9; Moving up and down in the vertical direction, the transmission wheel 9 is connected to the support base in rotation; the protruding rod 8 is located below the transmission wheel 9 and the bottom of the protruding rod 8 is connected above the vibrating plate 5, and the transmission wheel 9 The vibrating plate 5 is driven by the protruding rod 8 to vibrate with different intensities; among them, the vibrating plate 5 has a tendency to move upwards without external force, and the transmission wheel 9 is combined with the protruding rod 8, and the transmission wheel 9 rotates one circle , the vibrating plate 5 sequentially completes a cycle of rotation with different intensities, and vibrates the same asphalt layer wit...

Embodiment 2

[0046] A kind of using method of the rapid vibration mechanism of road and bridge construction asphalt, using the rapid vibration mechanism of road and bridge construction asphalt described in embodiment 1, it is specifically described below:

[0047] A method for using a fast vibrating mechanism for road and bridge construction asphalt, the specific steps are:

[0048] a. Using the rapid vibration mechanism described in Embodiment 1, the first groove 904 is located at the bottom, and the vibration plate 5 moves upward until the convex rod 8 and the first groove 904 are pressed against the upward movement of the vibration plate 5 Constraints are generated, the transmission wheel 9 rotates, and the protruding rod 8 is pushed down until the second protrusion 902 is at the bottom, the vibrating plate 5 moves to the lowest position, and the vibrating plate 5 completes a relatively high-intensity vibration;

[0049] b. The transmission wheel 9 continues to rotate, and the vibrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com