Road marking equipment with circulated stirring function

A technology of circulating stirring and scribing equipment, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems of easy sedimentation of paint, inconvenient adjustment of nozzle position, and difficulty in meeting people's use needs, so as to improve stirring efficiency, prevent paint sedimentation, Evenly mixed paint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

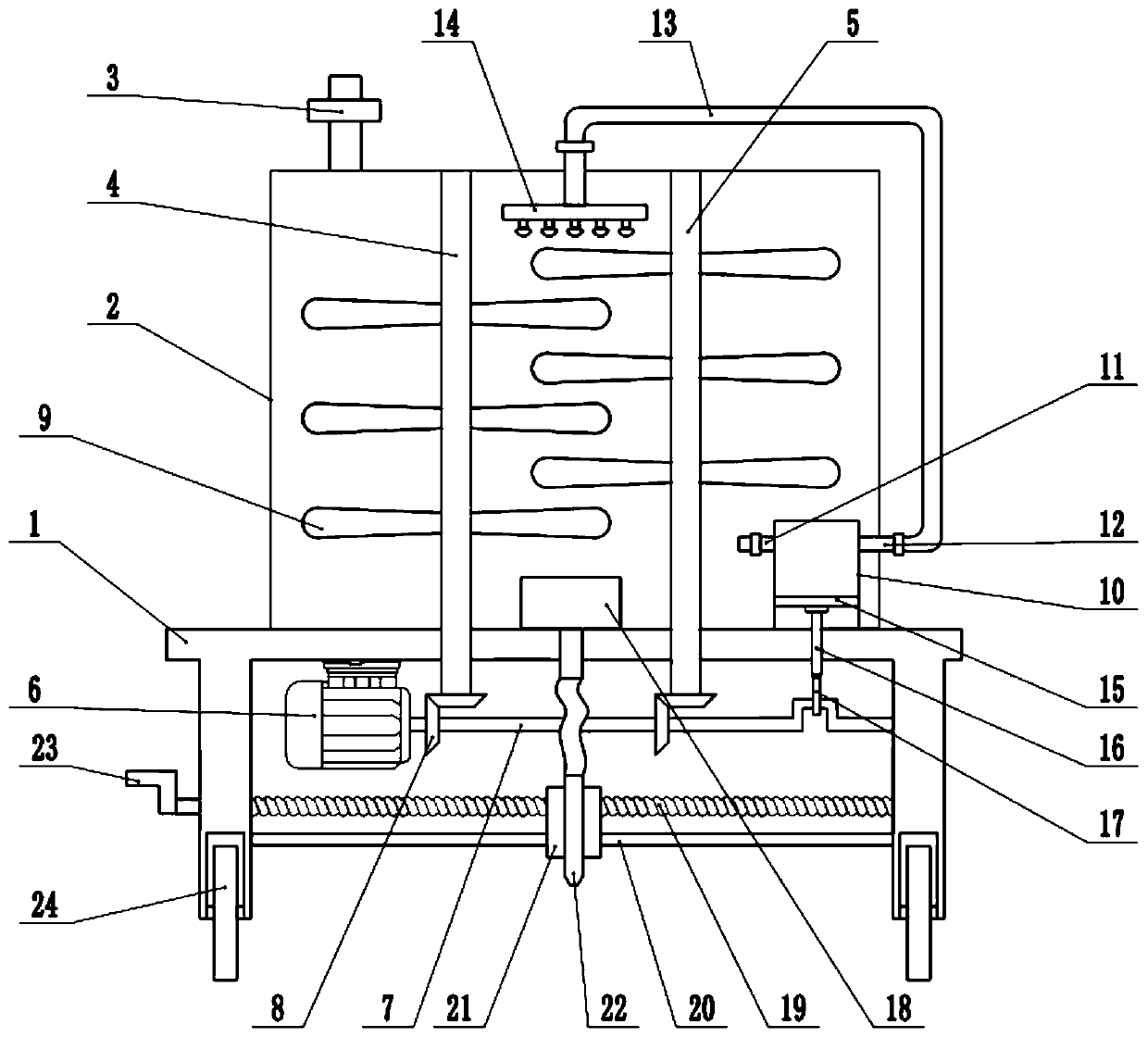

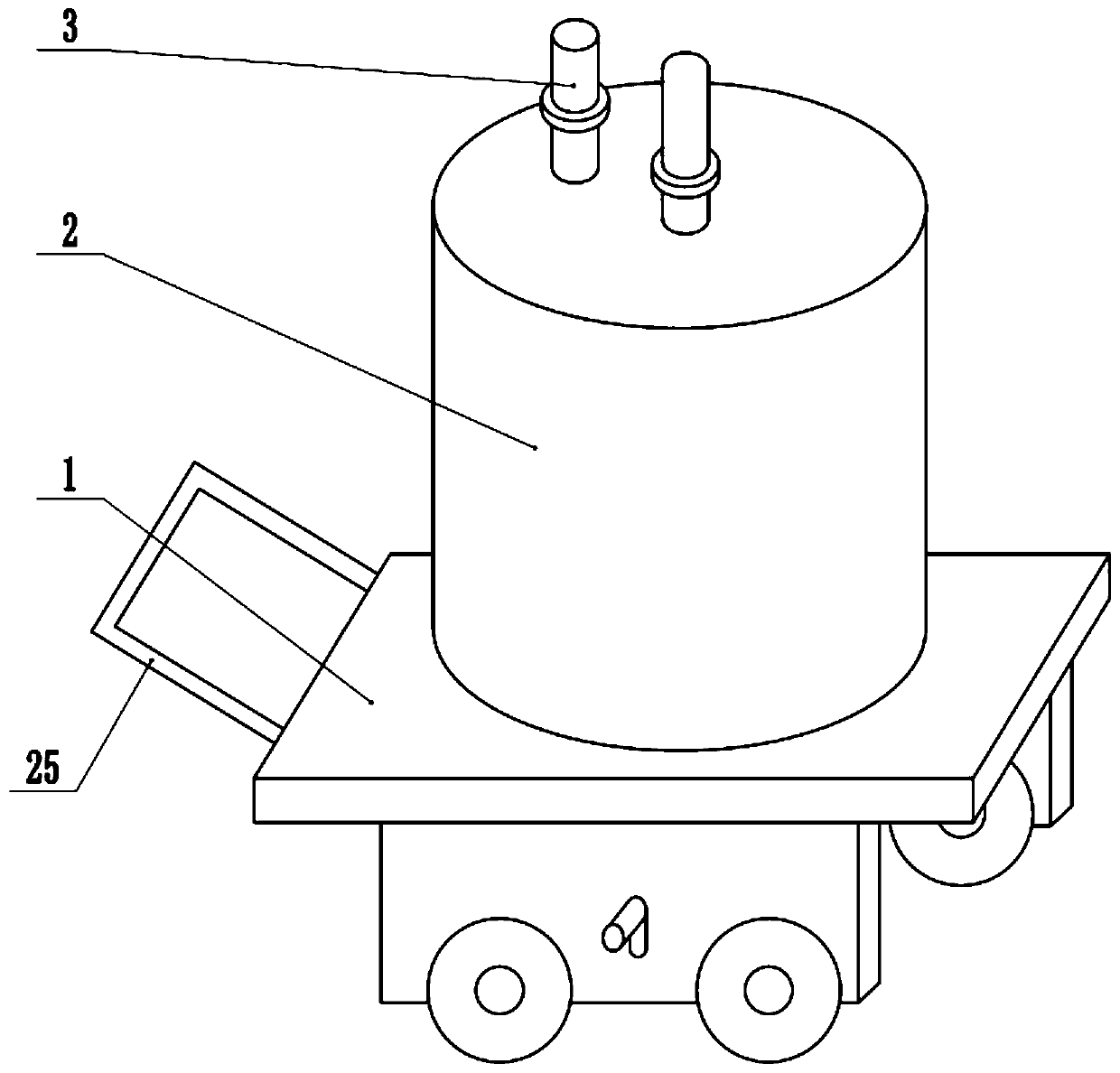

[0022] see Figure 1-3 , in an embodiment of the present invention, a road marking device with a circulating stirring function, comprising a fixed frame 1, a tank body 2, a water pump 18 and a spray gun 22, the upper surface of the fixed frame 1 is fixedly connected with a tank body 2, and the tank body A filling pipe 3 is installed on the top of the tank 2, and the filling pipe 3 communicates with the tank body 2. The paint is injected into the tank body 2 through the filling pipe 3. The bottom of the fixed frame 1 is fixedly connected with a motor 6, and the shaft end of the motor 6 is fixed. A crankshaft 7 is connected, and the end of the crankshaft 7 is rotatably connected with the fixed frame 1 .

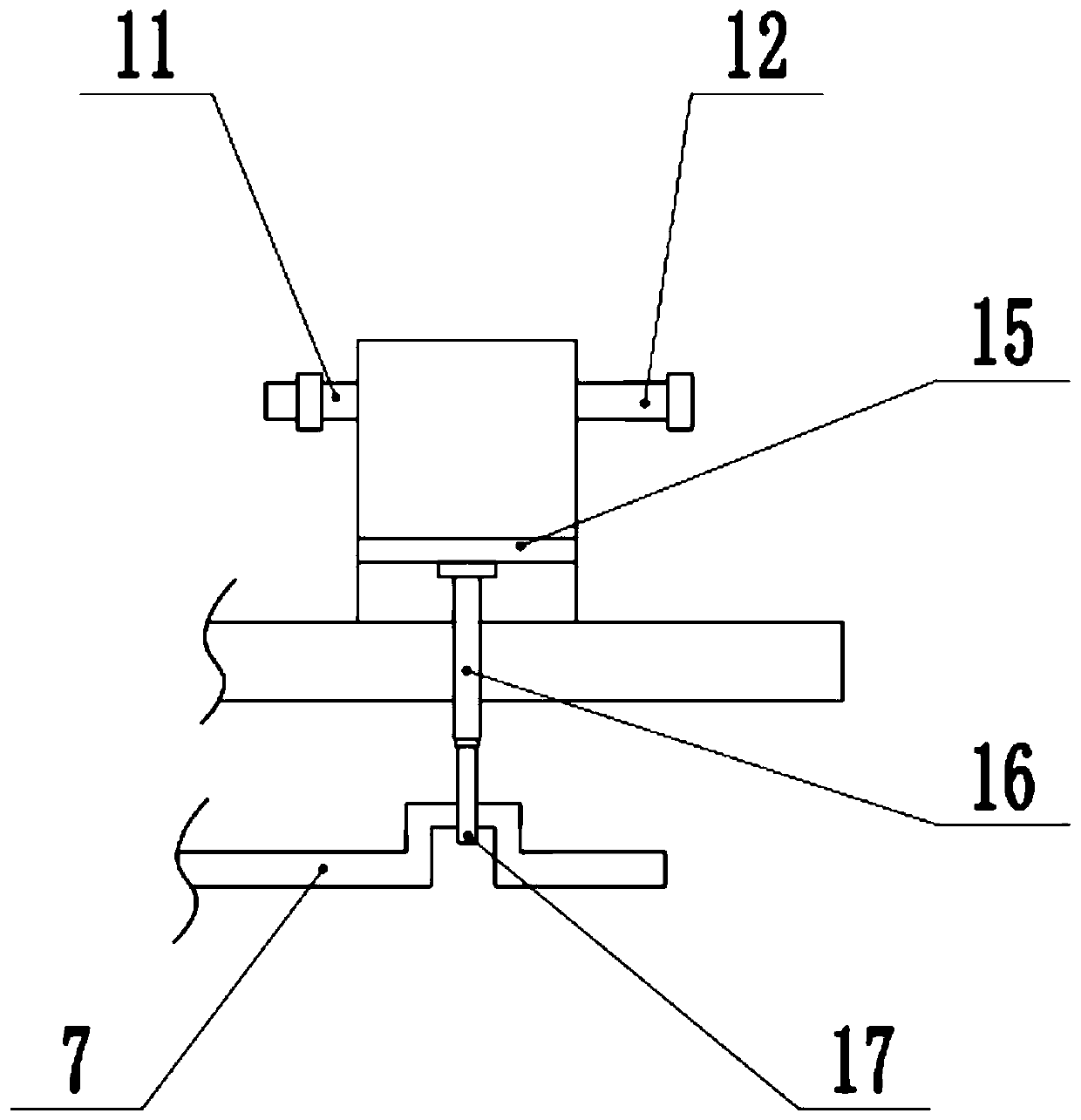

[0023] The inside of the tank body 2 is equipped with a circulation assembly, the circulation assembly includes a piston cylinder 10, a nozzle 14, a piston plate 15, a movable column 16 and a connecting rod 17, the inside of the tank body 2 is equipped with a piston cylinder 10...

Embodiment 2

[0026] On the basis of embodiment 1, a stirring mechanism is installed inside the tank body 2, and the stirring mechanism includes a left stirring shaft 4, a right stirring shaft 5 and a stirring blade 9, and the upper and lower ends of the left stirring shaft 4 and the right stirring shaft 5 are respectively connected to the The top and bottom of the tank body 2 are rotationally connected, the lower ends of the left stirring shaft 4 and the right stirring shaft 5 pass through the fixing frame 1 and extend to the bottom of the fixing frame 1, and the lower ends of the left stirring shaft 4 and the right stirring shaft 5 pass through the bevel gear respectively. The group 8 is connected with the crankshaft 7, and the left stirring shaft 4 and the right stirring shaft 5 are interlaced with the stirring blades 9. When the motor 6 is running, the crankshaft 7 is driven to rotate, thereby driving the left stirring shaft 4 and the right stirring shaft 5 to rotate. 9 Stir the paint in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com