A drilling machine for engineering supervision

A drilling machine and supervision technology, which is applied in the fields of infrastructure engineering, construction, and on-site foundation soil survey, etc., can solve the problems such as the inability to control the stable distance between the drop hammer and the drilling probe, and the inaccurate detection data. Detect the accuracy of data, improve the accuracy, improve the effect of statistics and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

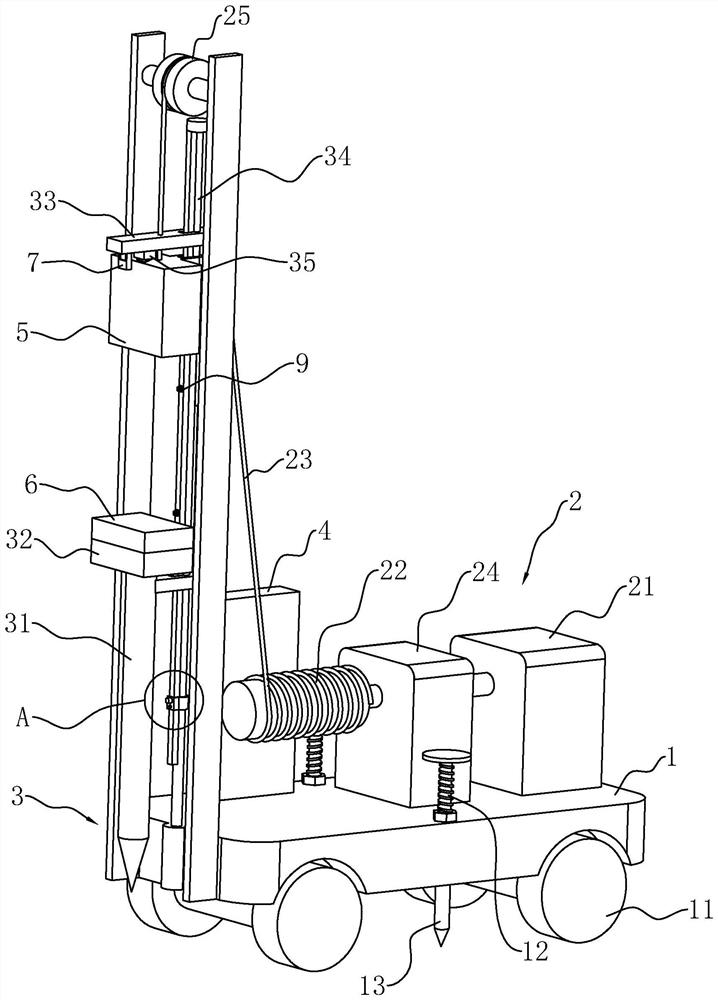

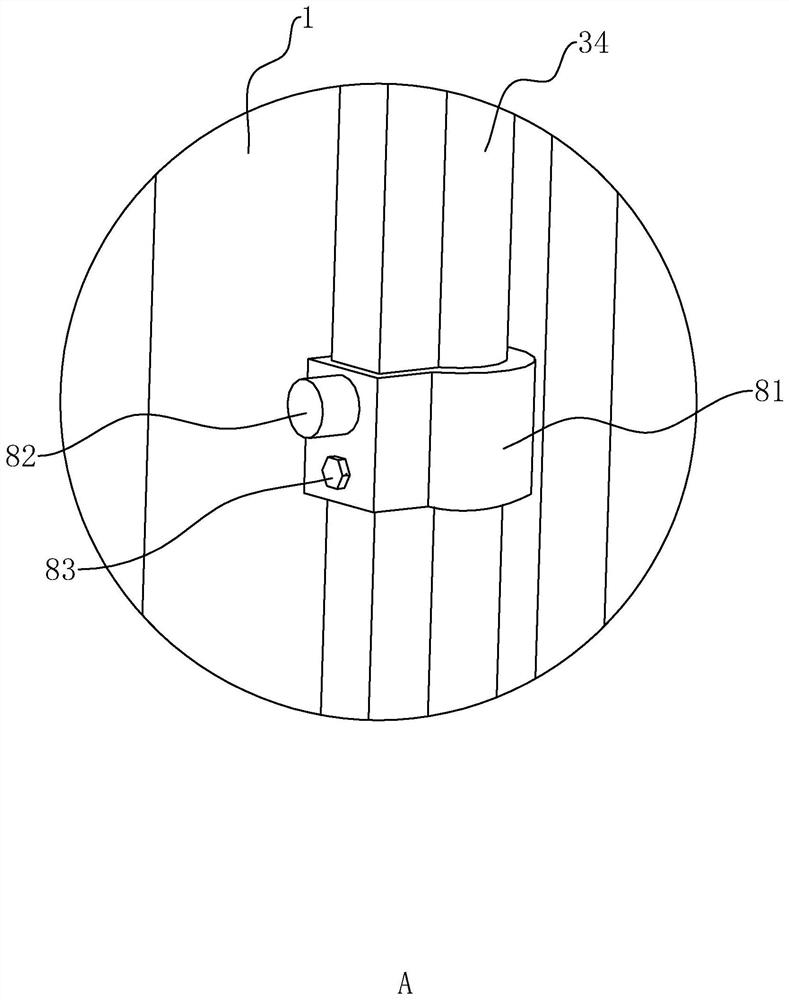

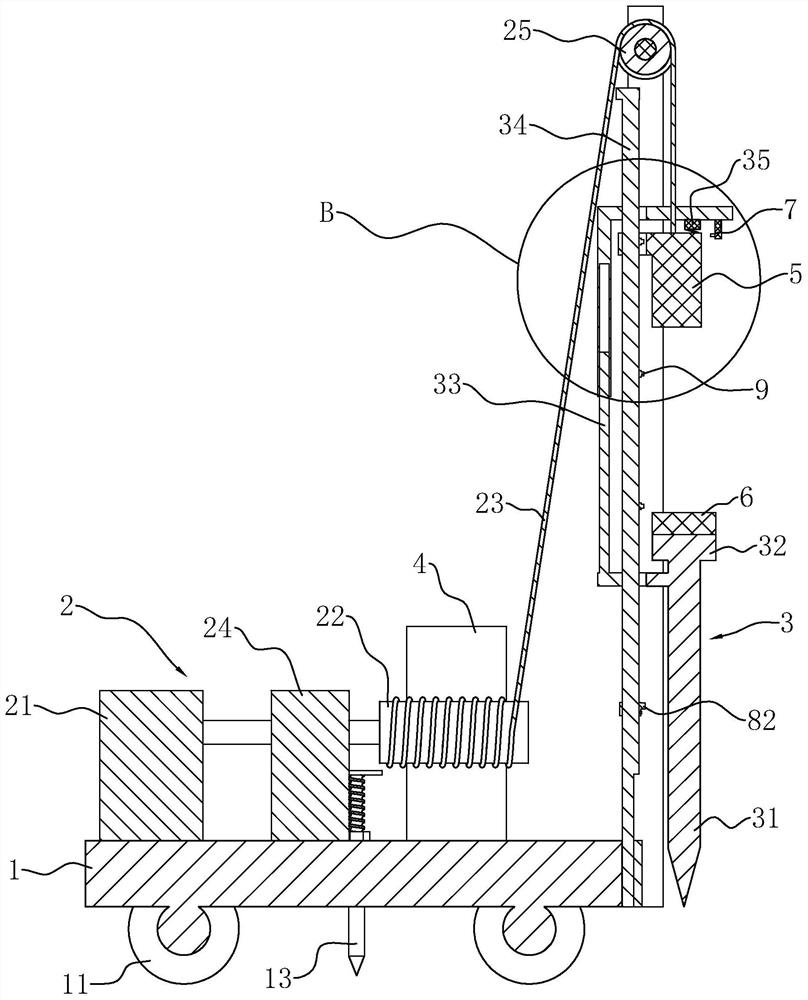

[0037] Refer to the accompanying drawings to further explain the drilling machine for engineering supervision.

[0038] A drilling machine for engineering supervision, such as figure 1 As shown, it includes a frame 1, a lifting mechanism 2, a ramming mechanism 3 and a PLC controller 4 respectively arranged on the frame 1, the lifting mechanism 2 is connected with a tamper 5, and the PLC controller 4 is connected with the lifting mechanism 2, the ramming mechanism Brazing mechanism 3 is electrically connected.

[0039] Such as figure 1 As shown, wherein, the bottom end of the frame 1 is symmetrically provided with a plurality of rollers 11, and threaded rods 12 are threaded on the frame 1, and anchor rods 13 are fixedly arranged at the ends of the threaded rods 12. During work, through The anchor rod 13 is inserted into the ground to realize the purpose of fixing the frame 1 .

[0040] Such as figure 1As shown, the brazing mechanism 3 includes a probe 31, a ramming part 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com