Folding type plant house

A foldable, plant-based technology, which is applied in the field of plant houses, can solve problems such as difficulty in transportation and installation of plant rooms, waste of resources, and shaking, and achieve the effect of reducing transportation safety and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

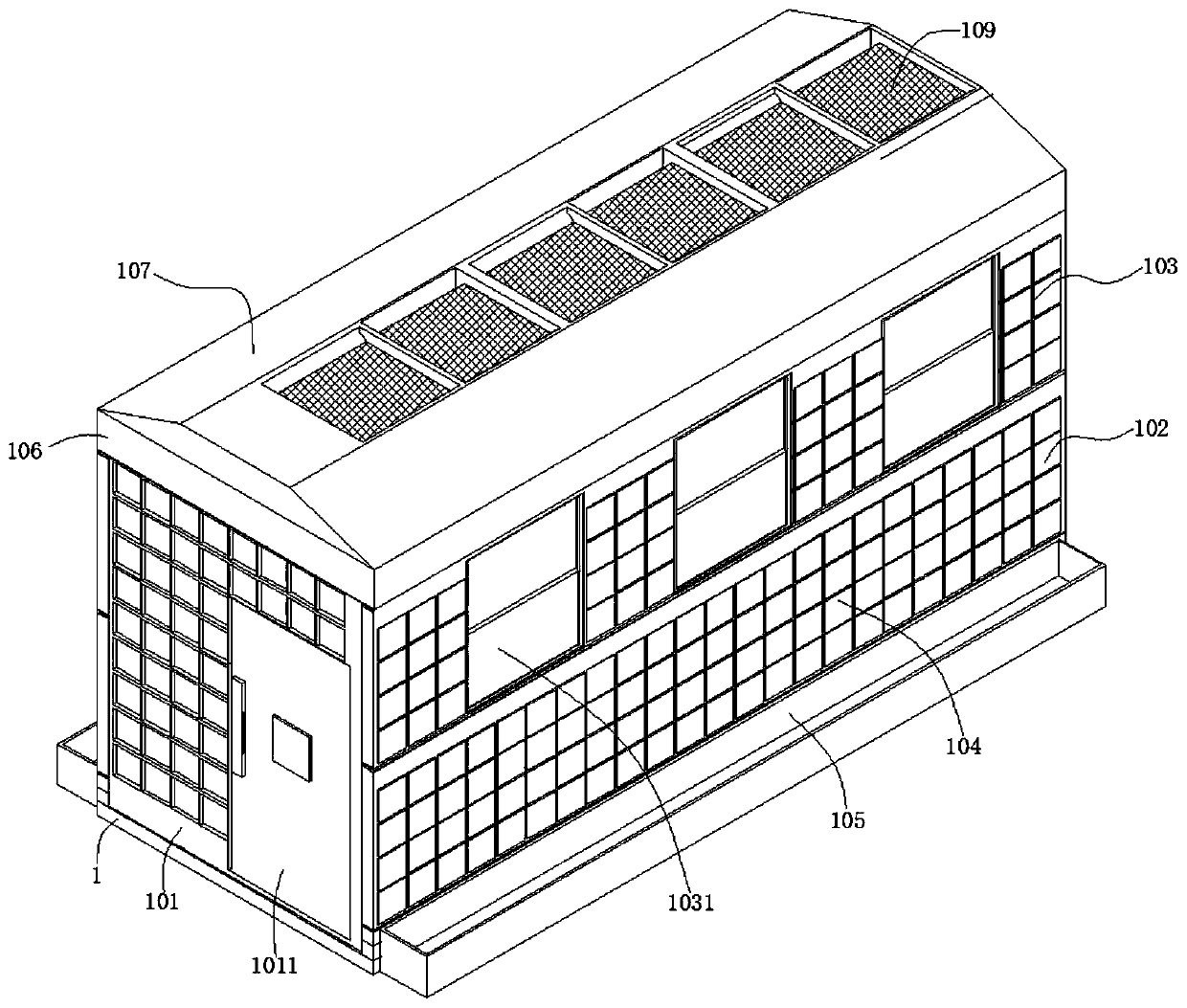

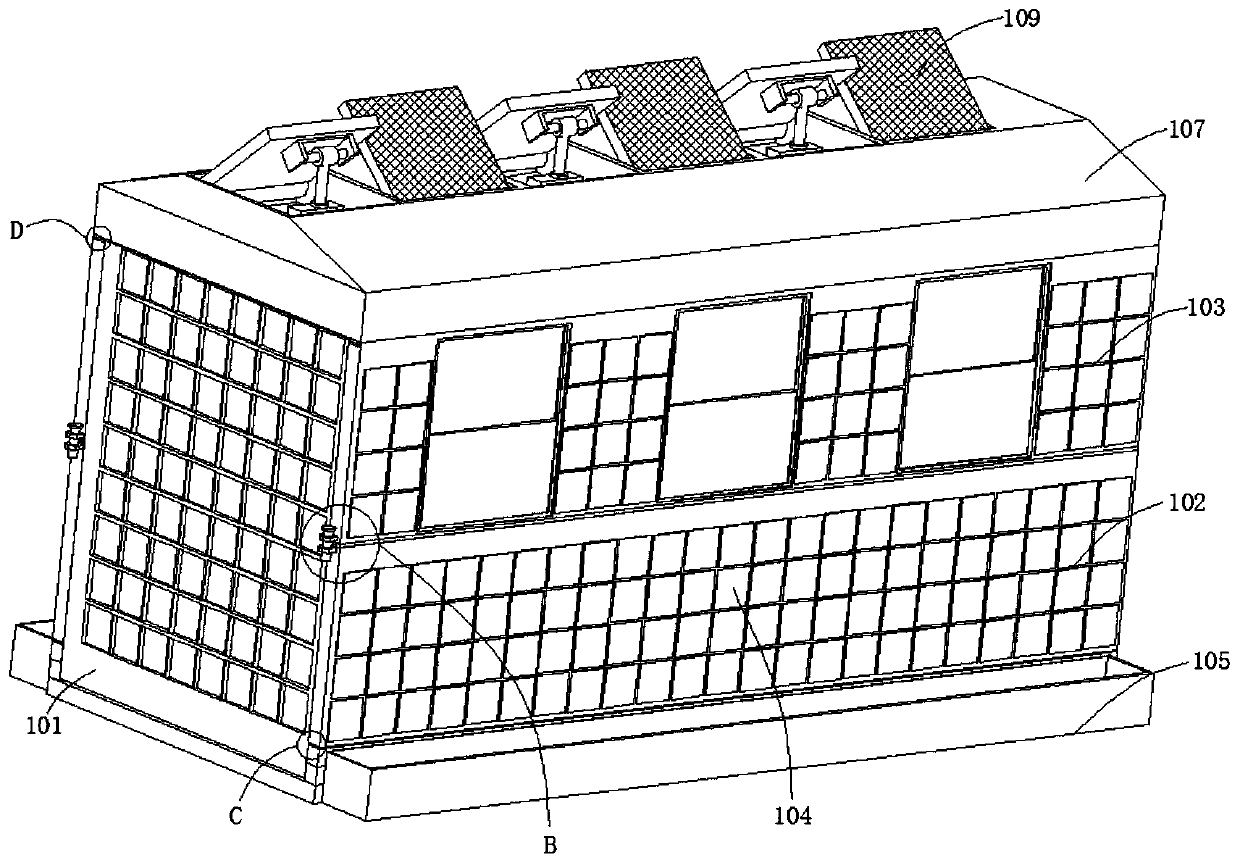

[0036] refer to Figure 1-10 , a foldable plant room, comprising a plant room base plate 1, a first rotating rod 2 is rotatably connected to the plant room base plate 1, a first connecting plate 201 and a second connecting plate 202 are fixedly connected to the first rotating rod 2, the second A connecting plate 201 is fixedly connected with the first room plate 101 by screws, and the second connecting plate 202 is fixedly connected on the plant room base plate 1 by screws. The second rotating rod 4, the third connecting plate 401 and the fourth connecting plate 402 are fixedly connected on the second rotating rod 4, the second room board 102 is fixedly connected on the third connecting plate 401, and the fourth connecting plate 402 is fixed by screws Connected to the connecting block 110, the second room plate 102 is rotatably connected with the third rotating rod 3, the third rotating rod 3 is fixedly connected with the fifth connecting plate 301 and the sixth connecting pla...

Embodiment 2

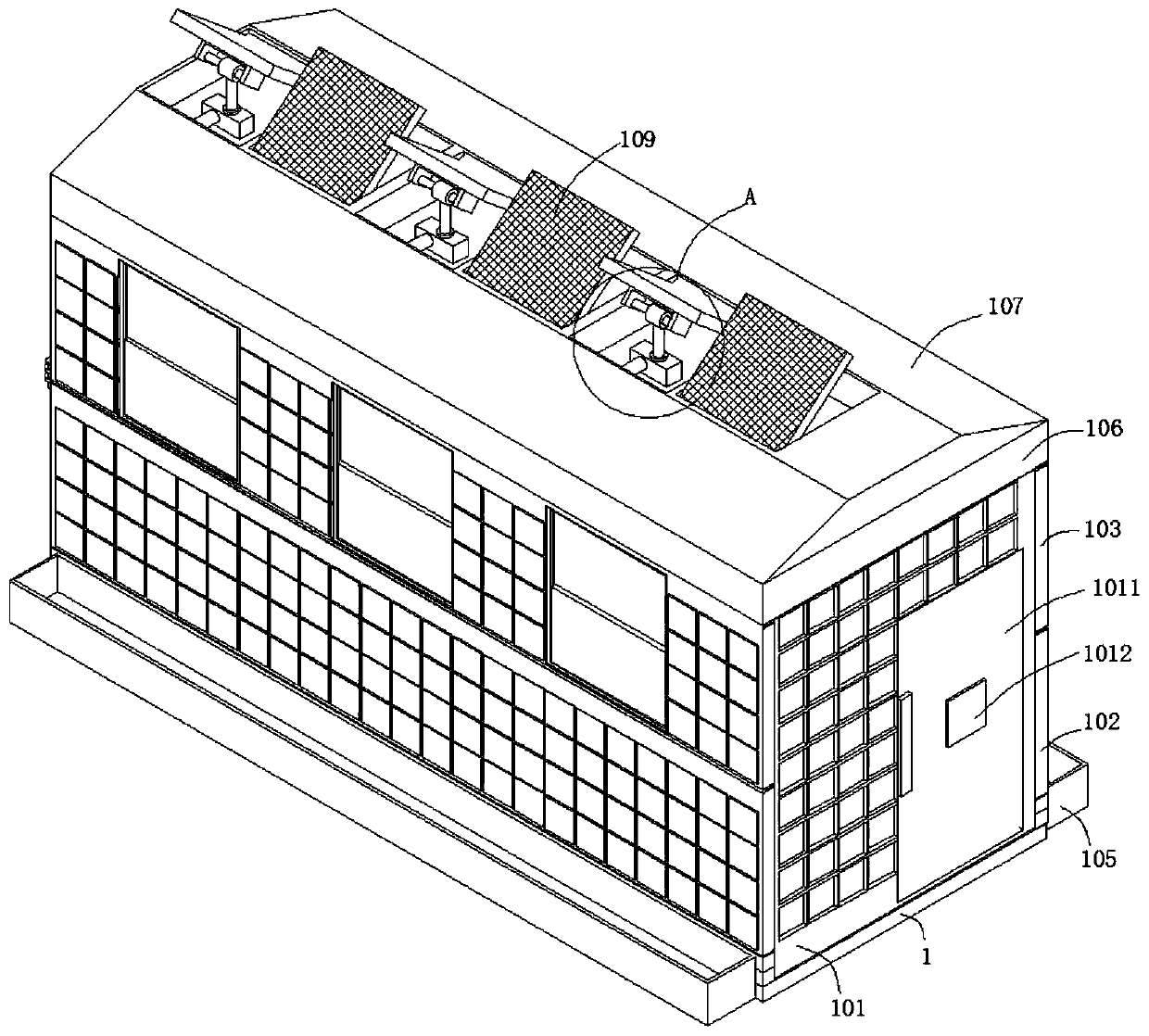

[0040] refer to Figure 1-10 , a foldable plant house, basically the same as Embodiment 1, the difference is that a trapezoidal plate 107 is fixedly connected to the plant roof plate 106, and a placement groove 108 is opened on the trapezoidal plate 107, and a solar energy is connected to the rotation in the placement groove 108 Plate 109.

[0041] The bottom wall of the solar panel 109 is fixedly connected with a U-shaped block 1084, and the U-shaped block 1084 is rotatably connected with a rotating rod 1085. A chute corresponding to the slide block 1082 is provided inside the slide block 108 , the slide block 1082 is fixedly connected with a first electric telescopic rod 1083 , and the driving end of the first electric telescopic rod 1083 is connected with the connection sleeve 1086 .

[0042] A second electric telescopic rod 1081 is fixedly connected to the plant roof board 106, and the driving end of the second electric telescopic rod 1081 is fixedly connected to the side...

Embodiment 3

[0045] refer to Figure 1-3 , a foldable plant house, which is basically the same as Embodiment 2, furthermore, a rainwater collection box 105 is fixedly connected to the plant house substrate 1, and the rainwater collection box 105 is placed directly below the end of the trapezoidal plate 107.

[0046] In rainy weather, rainwater falls on the trapezoidal plate 107, and the rainwater falling on the trapezoidal plate 107 will slide down with the trapezoidal plate 107, and the rainwater that falls will fall in the rainwater collection box 105 directly below the trapezoidal plate 107 end, thereby Realize the recycling of water resources

[0047] refer to Figure 1-2 , a password door 1011 is connected to the first room board 101 .

[0048] A handle is fixedly connected to the coded door 1011, and a coded board 1012 is provided on the coded door 1011, and the model of the coded board 1012 is SEL-310.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com