Self-insulation composite shear wall structure and construction technology

A technology of laminated shear walls and construction technology, which is applied in the direction of thermal insulation, walls, and building components, can solve the problems of laminated shear walls such as lack of self-insulation methods, limited application range, and short boards of bonding strength, and achieve improved The effect of short board, increased range of use, and increased external contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] S1: Preliminary preparation: firstly, according to the special construction plan of the design drawings and the layout of component hoisting, select the appropriate hoisting machinery, and provide training and safety technical disclosure to relevant technical personnel and workers. It is necessary to ensure that there are no obstacles in the working range. The opposite position of the components needs to be flat, solid and have drainage measures. The construction machinery entering the site needs to be pre-checked and regularly maintained during use;

[0044] S2: Measurement and setting out: release the specific position line of each laminated shear wall structure on the installation surface according to the drawings, and carry out effective review;

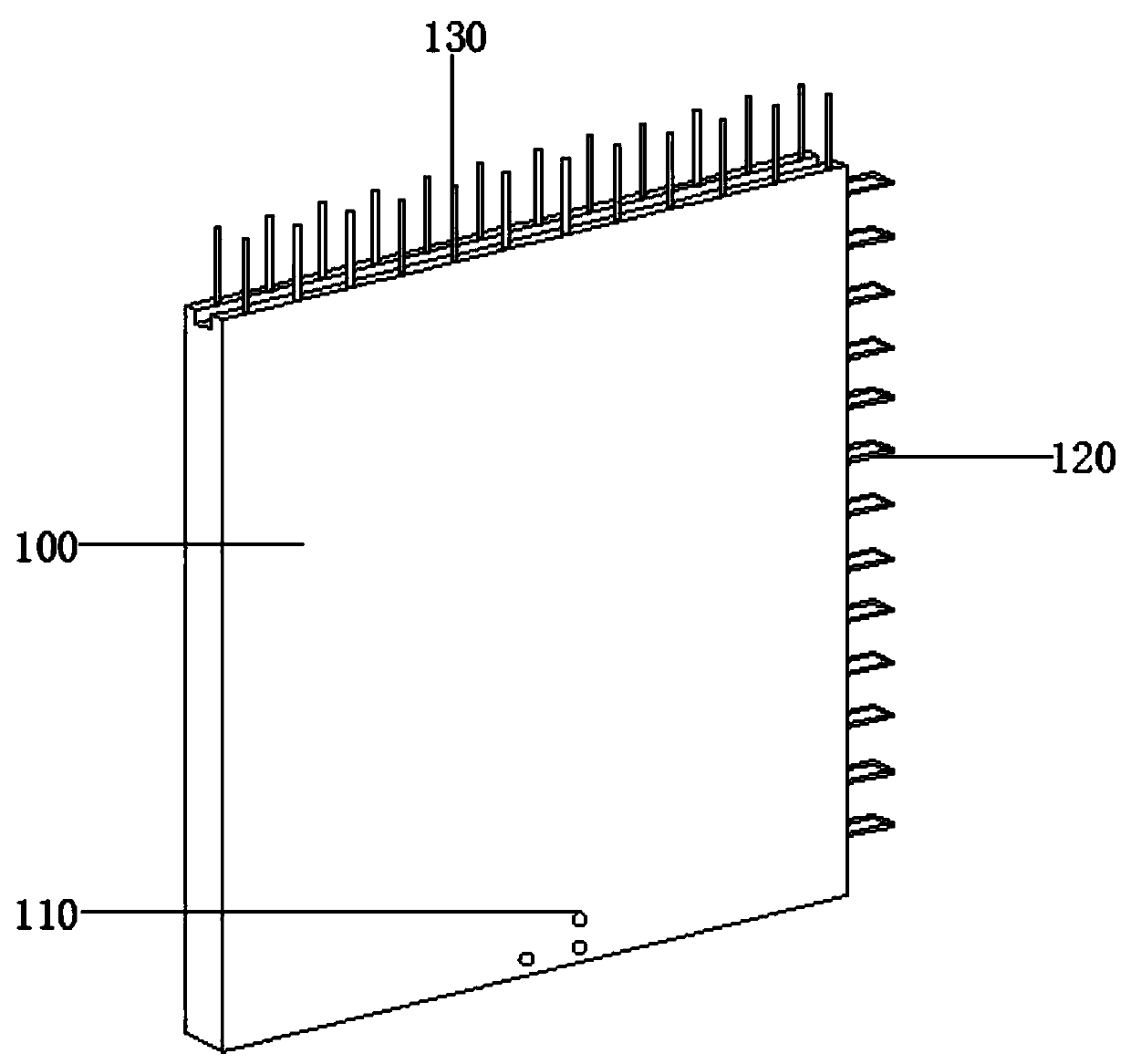

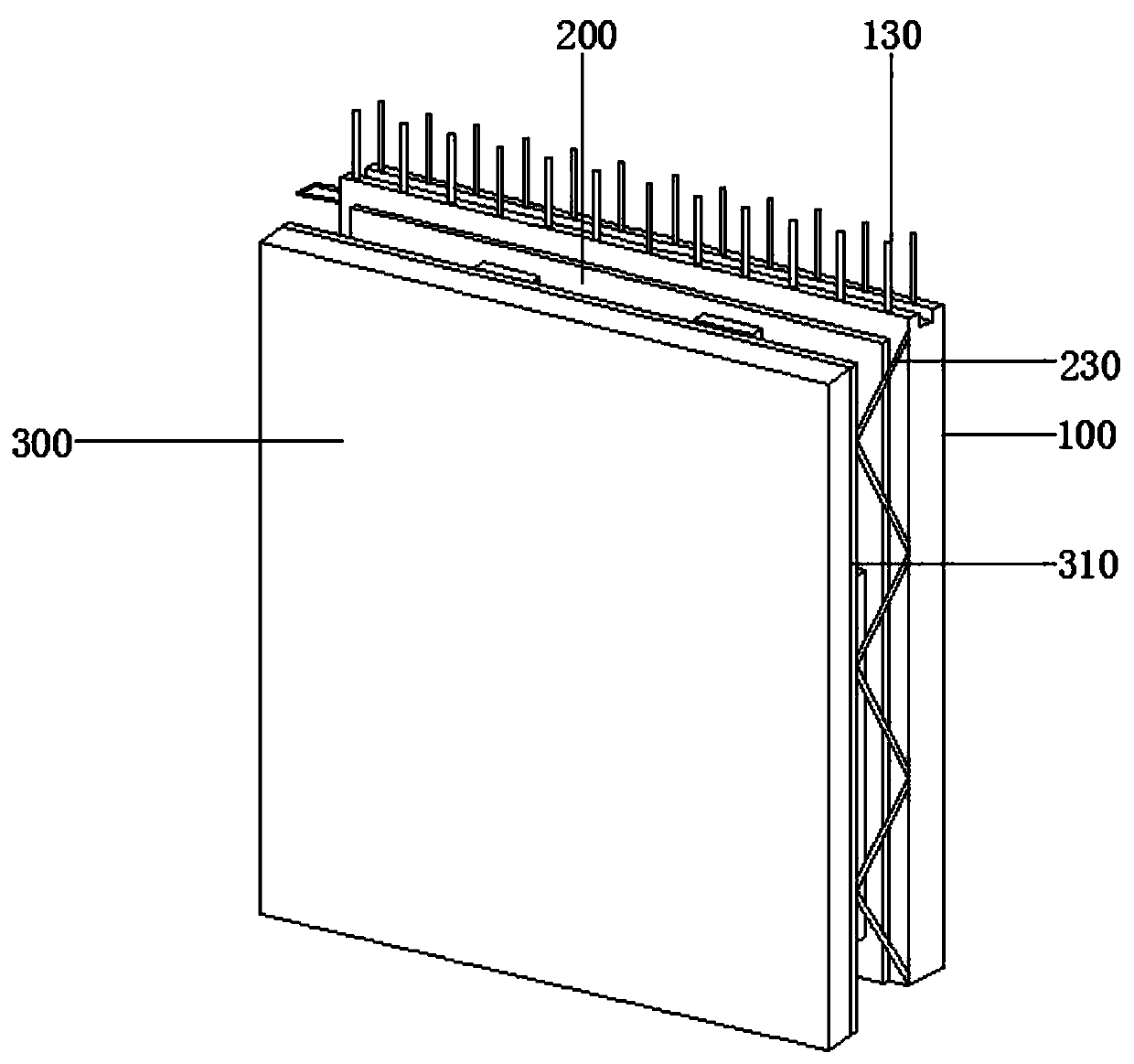

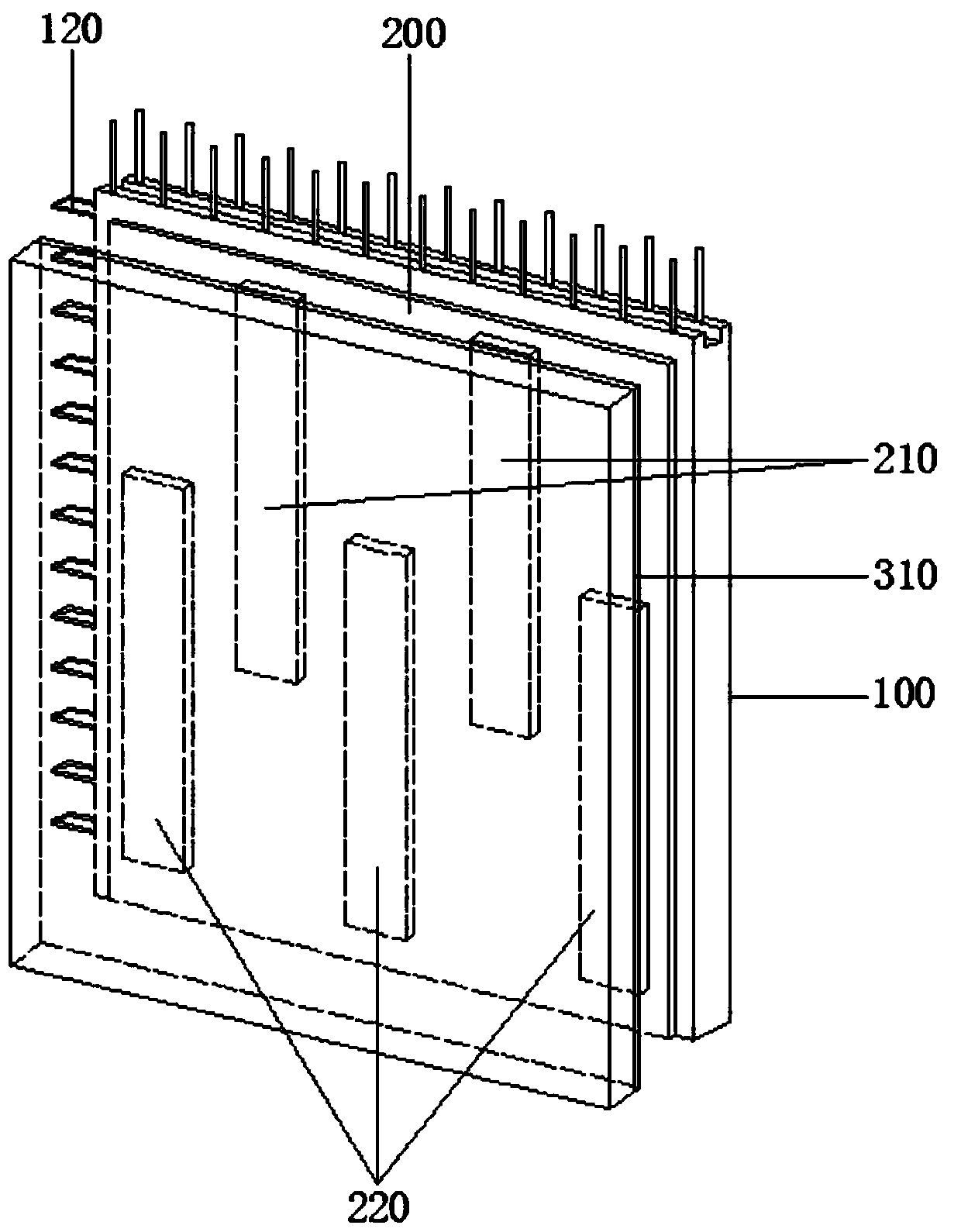

[0045] S3: Steel bar inspection: It is necessary to check whether the reserved positions of the side steel bars 120, embedded steel bars 130 and connecting steel bars 230 meet the standards, and the position deviation shall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com