A kind of dry-hanging wall brick structure and construction method thereof

A wall brick and dry-hanging technology, which is applied in building structure, covering/lining, construction, etc., can solve the problems of poor deformation resistance, poor earthquake resistance, and easy falling off of dry-hanging wall bricks, so as to achieve reasonable force and earthquake resistance Good performance and many patterns and styles of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

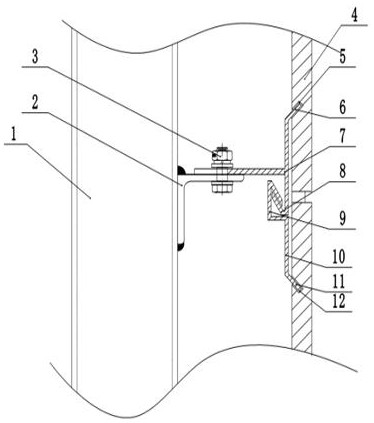

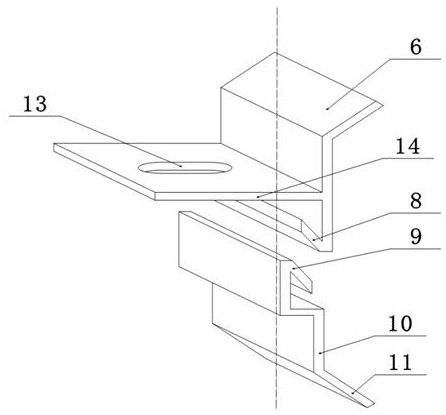

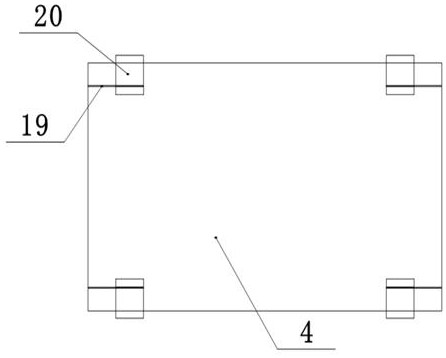

[0040] Embodiment 1: see Figure 1-Figure 3 , a dry-hanging wall brick structure, including a wall and wall bricks 4, and also includes a column 1 connected to the outer wall of the wall, the column 1 is a channel steel or I-beam detachably connected to the wall, channel steel or I-beam The beam can be used multiple times through detachable connections, saving costs. The side of the column 1 away from the wall is distributed from top to bottom with multiple connecting pieces arranged horizontally. The connecting pieces include vertical plates and horizontal plates, wherein the vertical plates and The column 1 is fixedly connected; several anchoring sets 20 are arranged on the horizontal plate.

[0041] The anchor kit 20 includes a connecting support plate 14, an upper hanger and a lower hanger. The connecting support plate 14 is detachably connected to the connecting piece 2; the horizontal plate of the connecting piece 2 is provided with a number of connecting holes 13, and t...

Embodiment 2

[0053] Example 2, see Figure 4 The difference between this embodiment and Embodiment 1 is that: the upper end of the upper hanging part is bent horizontally in a direction away from the column 1 and then connected to a vertically arranged first block 16, so that the upper hanging part 7 forms a T-shaped structure as a whole; The lower end of the hanging part 10 is bent horizontally in the direction away from the column 1 and connected to a vertically arranged second block 18, so that the upper hanging part 7 forms a T-shaped structure as a whole; the upper hanging groove and the lower hanging groove on the back of the wall tile 4 They are respectively formed into T-shaped slots corresponding to the upper hanging part and the lower hanging part, and the ends of the upper hanging groove and the lower hanging groove pass through the corresponding ends of the wall bricks to form an open end. The upper hanging part and the lower hanging part of the anchor kit Snap into the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com