A flip-type drill floor manipulator

A manipulator and flip-type technology, which is applied in the direction of drill pipe, drill pipe, earthwork drilling and mining, etc., can solve the problems of affecting the channel operation and limited installation position, and achieve the reduction of mechanical collision risk, small space occupied by work, and simple installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

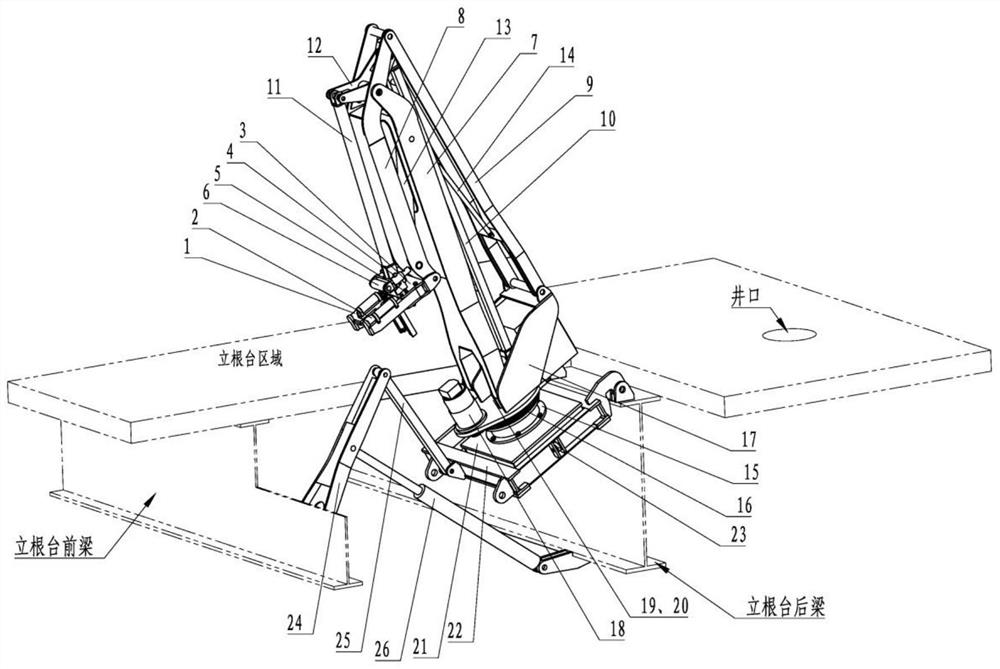

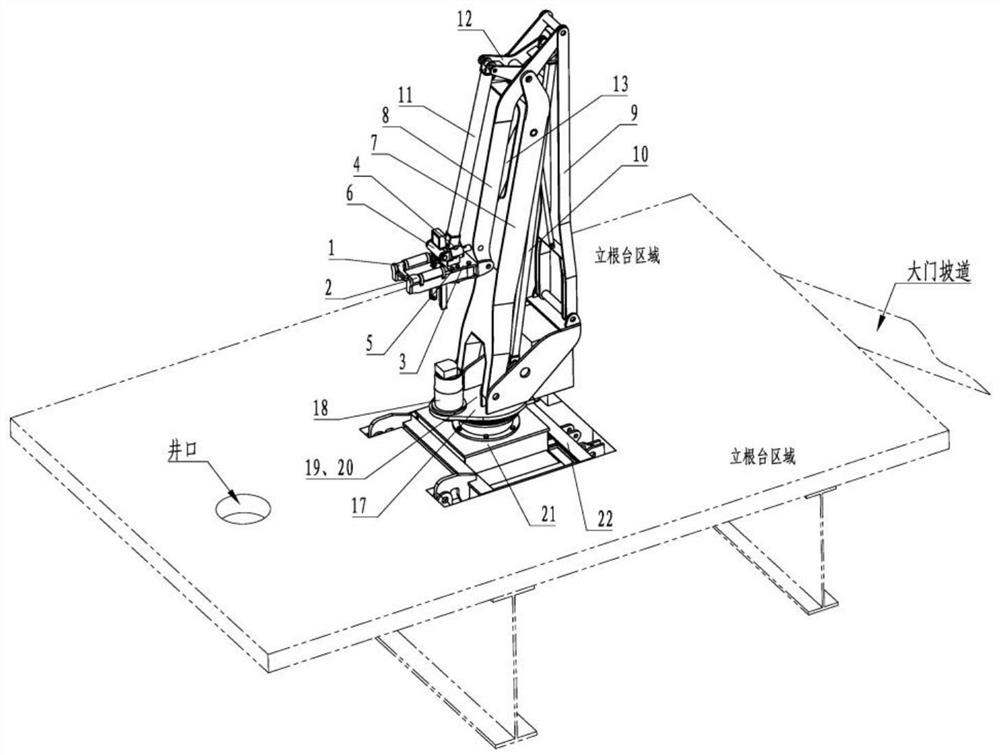

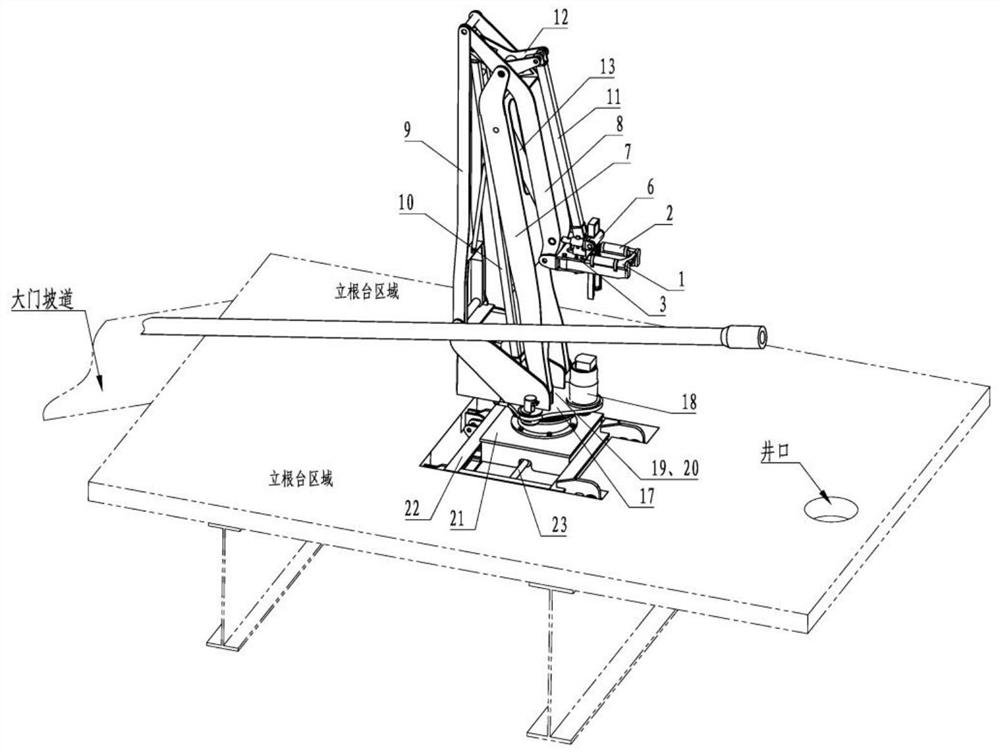

[0026] A structure of a flipping drill floor manipulator, such as figure 1 and figure 2 As shown, including the pincer head frame body 3, the pincer head frame body 3 is provided with a middle hole, and the middle hole of the pincer head frame body 3 is hinged to the left jaw assembly 1 and the right jaw assembly 2 through the latch II 5, and the pincer head frame body Body 3 is hinged at one end of auxiliary arm 8, the other end of auxiliary arm 8 is hinged with one end of pull rod 9, the other end of pull rod 9 is hinged with mount 17, one side of the upper end of auxiliary arm 8 is hinged with one end of main arm 7, and at the same time, the other side of the upper end of auxiliary arm 8 is The middle link 12 is hinged, the other end of the main arm 7 is hinged to the mounting seat 17, the long leveling link 10 is hinged between the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com