Method for synchronously characterizing anisotropic yield and hardening constitutive parameters of metal material

An anisotropic, metal material technology, applied in analyzing materials, testing material strength by applying repetitive force/pulse force, and testing material strength by applying stable tension/pressure, etc., can solve problems such as poor practicability and achieve practicality Good, parameters characterize the effect of reducing the amount of calculation and calculation time, simplifying the experimental equipment and experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: use finite element software to construct the test piece configuration, set the material constitutive model and model parameters, simulate the test piece uniaxial tension and cyclic tension-compression experiments, derive the simulated data of strain and load, and simulate Data Substitution written by The parameter characterization program identifies the constitutive parameters of the material based on the simulated data, and compares the characterization results with the input model parameters to verify the accuracy of the method.

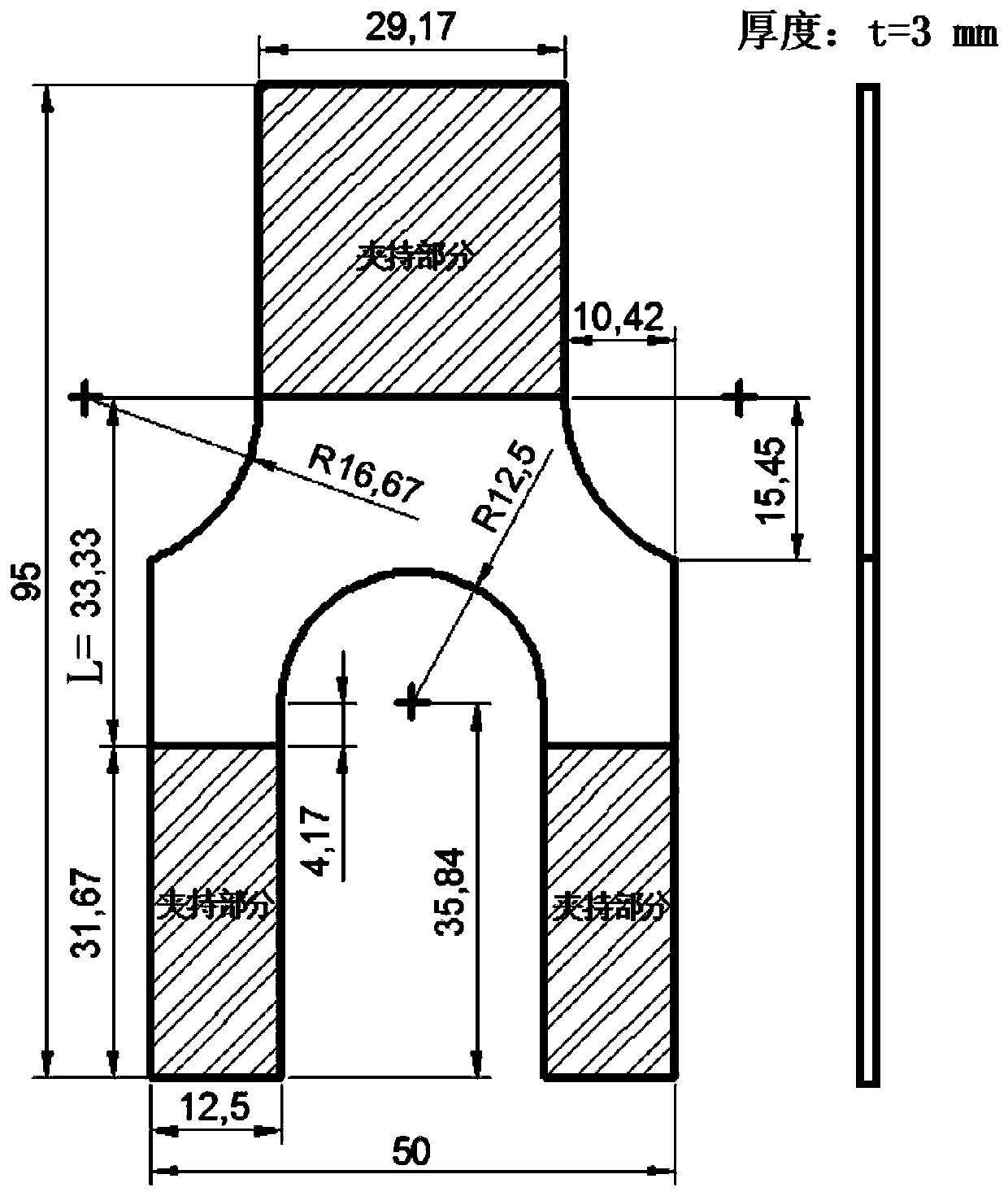

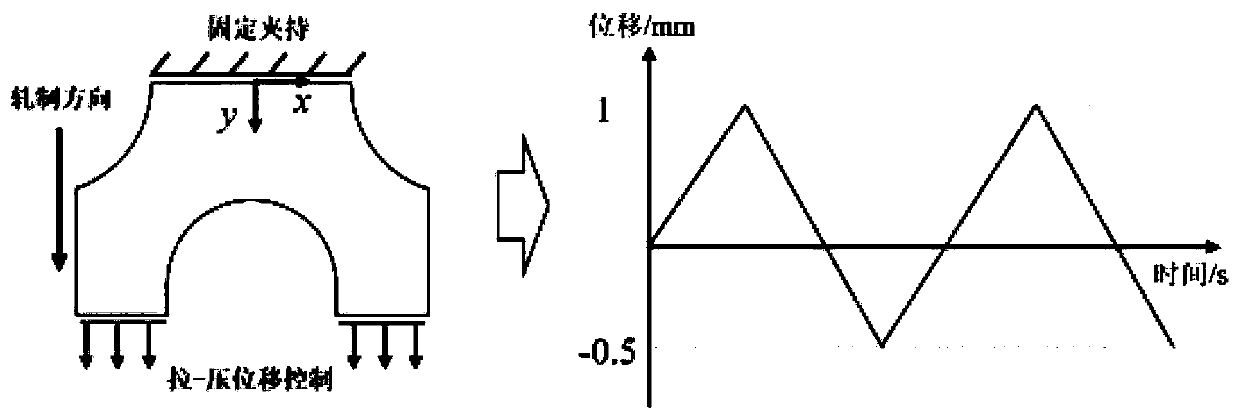

[0030] Step 1. In the finite element software Build the test piece model. In order to keep the external deformation of the specimen at a lower level under a certain compressive load, by adjusting the configuration of the specimen, part of the material on the rectangular specimen is removed, so that part of the compressive load can be transformed into shear deformation, and at the same time, the deformation of the specimen can...

Embodiment 2

[0068] Example 2: Experimental method for characterization of anisotropic yield and plastic hardening parameters of metal materials. The selected material is AZ31B magnesium alloy. The difference between this embodiment and Embodiment 1 is that the deformation field of the magnesium alloy specimen is measured by the digital image correlation full-field deformation measurement system, the load value is measured by the testing machine system, and other steps, such as specimen configuration, loading process, and data substitution , virtual field selection, program operation, etc. are the same as those in Embodiment 1.

[0069] This method can also be applied to the characterization of anisotropic constitutive parameters of aluminum alloys, advanced high-strength steels, and other metal materials. The applicability of different models varies according to different materials. modification, and then adopt the characterization method proposed by the present invention to characterize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com