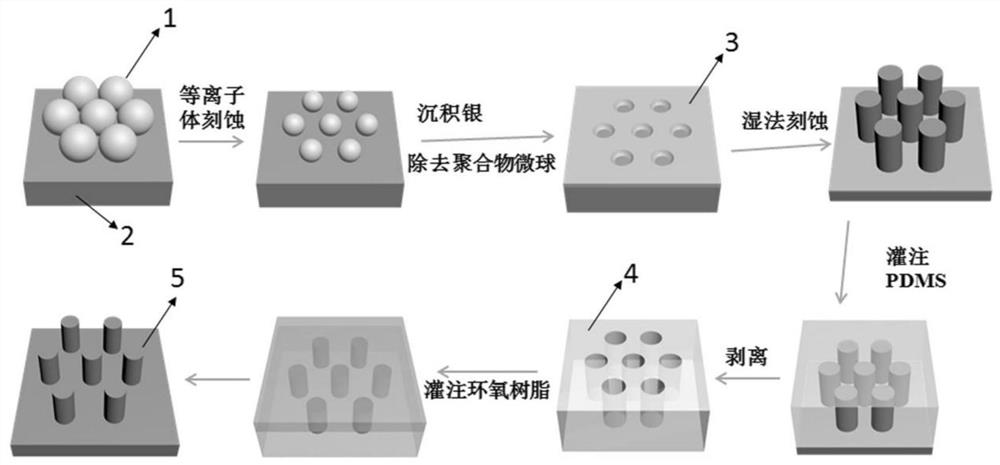

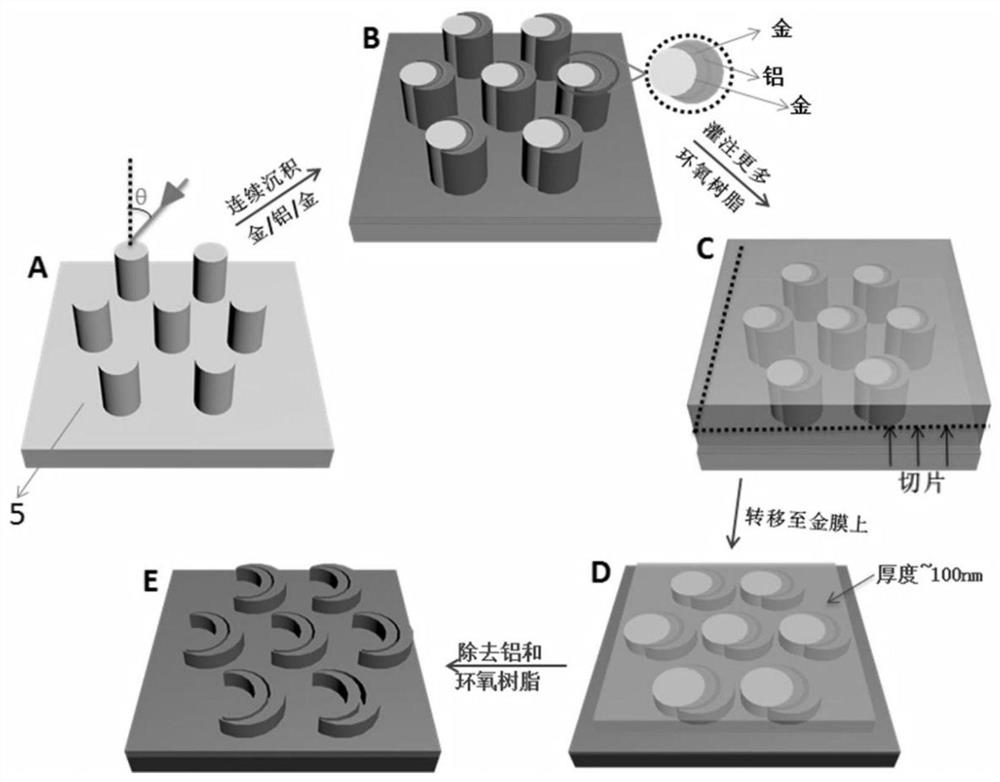

A periodic crescent-shaped nano-gap array and its preparation method

A nano-gap and crescent-shaped technology, applied in nanotechnology, material excitation analysis, instruments, etc., can solve the problems of expensive instruments, limited applications, low throughput, etc., and achieve simple and easy operation, high controllability, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

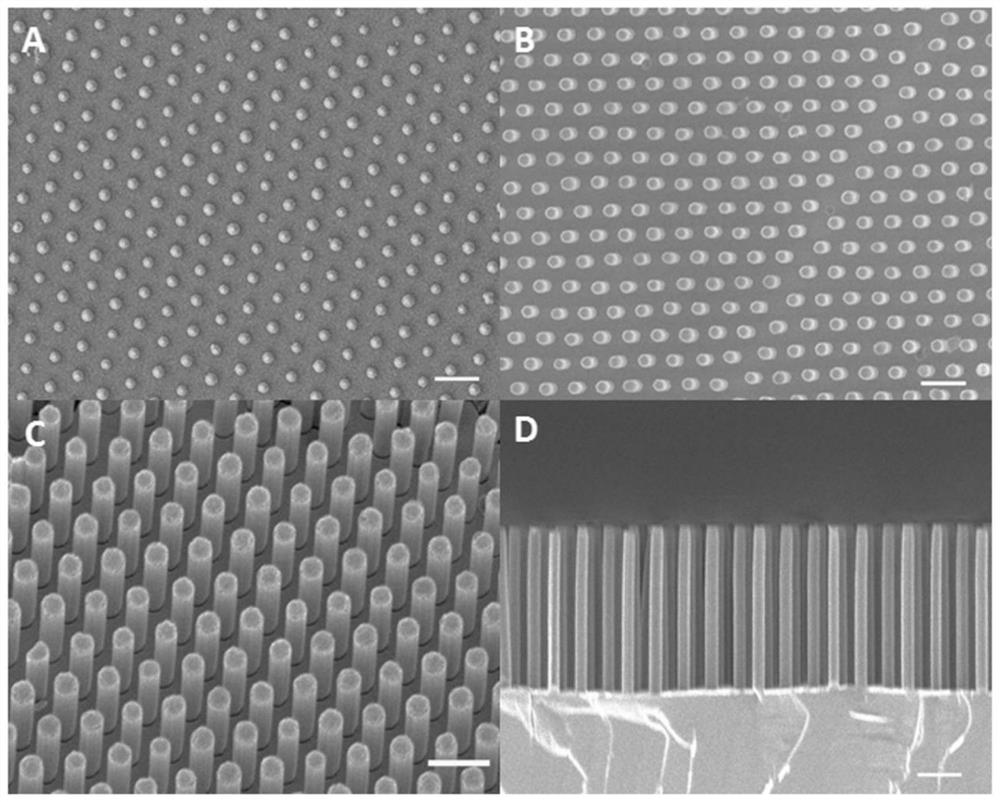

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of hydrophilic silicon substrate

[0037] Cut the silicon wafer into 2×2cm with a glass knife 2 size, put it into a mixture of concentrated sulfuric acid (mass fraction 98%) and hydrogen peroxide (30%) (volume ratio is concentrated sulfuric acid: hydrogen peroxide = 7:3), heat to 80°C, keep for 5h and let it cool to room temperature , Rinse with a large amount of deionized water to obtain a hydrophilic silicon wafer, then rinse the silicon wafer with ethanol, blow dry with nitrogen, and use an oxygen plasma machine to clean the surface for 3 minutes to obtain a hydrophilic and uniform surface.

Embodiment 2

[0038] Embodiment 2: Preparation of hydrophobic polystyrene microspheres

[0039] At room temperature, add 3 mL of deionized water to 1 mL of 5 wt % polystyrene microsphere dispersion with a diameter of 700 nm, perform ultrasonication for 10 min, centrifuge at 8900 rpm for 10 min, absorb the supernatant, and re- 3 mL of deionized water was added for sonication and centrifugation was performed again, after which the process was repeated 4 times. After absorbing the supernatant for the last time, add 3 mL of a mixture of ethanol and deionized water (the volume ratio of ethanol: deionized water is 1:1) to the solid, centrifuge at 8900 rpm for 10 min, absorb the supernatant, and then Add 3mL of ethanol and deionized water mixture to the remaining solid matter, sonicate and centrifuge again, then repeat this process 8 times, after the last suction of the supernatant, put the remaining solid matter in an oven at 30 After drying for 8 hours, a mixture of ethanol and deionized water ...

Embodiment 3

[0040] Example 3: Preparation of hexagonal close-packed monolayer polystyrene colloidal crystals

[0041] Use a disposable syringe to draw 0.2 mL of the ethanol and deionized water dispersion of hydrophobic polystyrene microspheres with a diameter of 700 nm prepared in Example 2, and use an instrument to slowly drop it onto the air-deionized water interface of the petri dish , add 80 μL of an aqueous solution of sodium lauryl sulfate with a mass concentration of 10wt% along the side of the petri dish, and let it stand for a while, and the polystyrene microspheres will form a single layer of hexagonal close-packed on the air-deionized water interface. form. Taking the hydrophilic silicon substrate obtained in Example 1 as an example, it is deep below the water surface, slowly lifted up from the bottom of the compact single-layer polystyrene microspheres, and placed on a filter paper with an inclined plane of 60° for natural drying, that is, on the silicon substrate. A monolaye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com