A kind of porous gold-silver alloy nanomaterial and its preparation method and application

A nanomaterial and silver alloy technology, applied in metal material coating process, nanotechnology, nanotechnology and other directions, can solve the problems of high preparation cost, hinder the adsorption of target molecules, complex preparation method, etc., and achieve low preparation cost and excellent surface. The effect of enhancing Raman scattering performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Specifically, the preparation method of the porous gold-silver alloy nanomaterial may include the following steps:

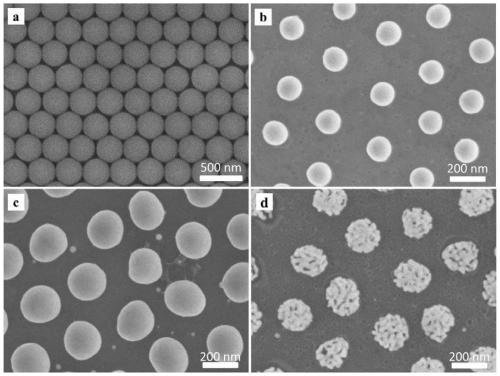

[0034]Step A, using a single-layer colloidal microsphere array with a colloidal microsphere diameter of 350-750 nm as a template, and using a physical deposition method to deposit a layer of gold film on the surface of the template, and then removing the single-layer colloidal microsphere array by heat treatment, Thereby, an ordered array of gold nanospheres is prepared.

[0035] Further: the specific implementation process of step A can include the following steps:

[0036] (1) Step A1, put the substrate into ethanol and deionized water successively for ultrasonic cleaning, ultrasonic cleaning is carried out in each liquid for 20 to 60 min, and then the cleaned substrate is dried (for example: can be placed in an oven to Drying at 60°C for 20min), and then placed in a UV-ozone cleaner for 20-60min irradiation to obtain a substrate with a hydrophilic sur...

Embodiment 1

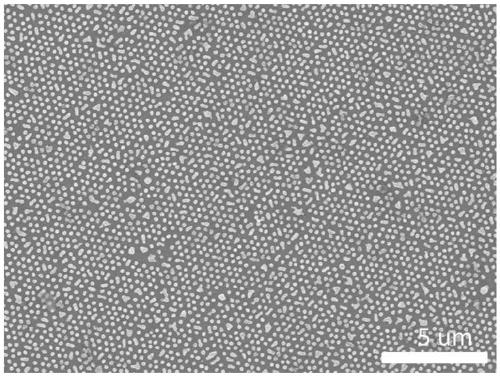

[0054] like Figure 10 As shown, a porous gold-silver alloy nanomaterial, the preparation method of which comprises the following steps:

[0055] Step a. Put the two substrates, the glass slide and the silicon wafer, into acetone, ethanol, and deionized water for ultrasonic cleaning in turn. Ultrasonic cleaning is carried out in each liquid for 20-60 minutes, and then the cleaned glass slide and silicon wafer are cleaned. Put them in an oven to dry at 60°C for 20 minutes, and then place the dried glass slides and silicon wafers in an ultraviolet-ozone cleaning machine for 20-60 minutes to obtain a glass slide substrate and a silicon wafer substrate with hydrophilic surfaces.

[0056] Step b. Take 40 mL of polystyrene colloidal microsphere suspension (2.5 wt.%) with a diameter of 350-750 nm of colloidal microspheres, mix it with an equal volume of ethanol, and then perform ultrasonic dispersion for 10-30 minutes to obtain a dispersion Uniform colloidal microsphere diameter is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com