A method for preparing au-ag core-shell nanoparticles under visible light

A nanoparticle and visible light technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor uniformity of Au-Ag core-shell nanoparticles and achieve excellent catalytic performance, The effect of uniform particle size and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Mix 150 μL trisodium citrate aqueous solution (50 mM), 120 μL AgNO 3 Aqueous solution (1 mM) and 250 μL HAuCl 4 The aqueous solution (20 mM) was added to 19.48 mL of deionized water, and stirred rapidly for 5-10 min to mix the substances evenly to obtain a mixed solution;

[0025] 2) The above mixed solution was placed under a 350W xenon lamp (with a 420nm filter), and irradiated for 1 h while stirring to generate Au nanoparticles in the solution, and then 0.3 mL of trisodium citrate aqueous solution was added to the above solution. (50mM) under a 350W xenon lamp (with a 420nm filter) with stirring, and to this solution was added 0.1mL of AgNO dropwise 3 Aqueous solution (50 mM), after the addition is complete, continue to stir and illuminate for 1 h. After the reaction, the Au-Ag core-shell nanoparticles were obtained by post-treatment, and the particle size was about 27 nm.

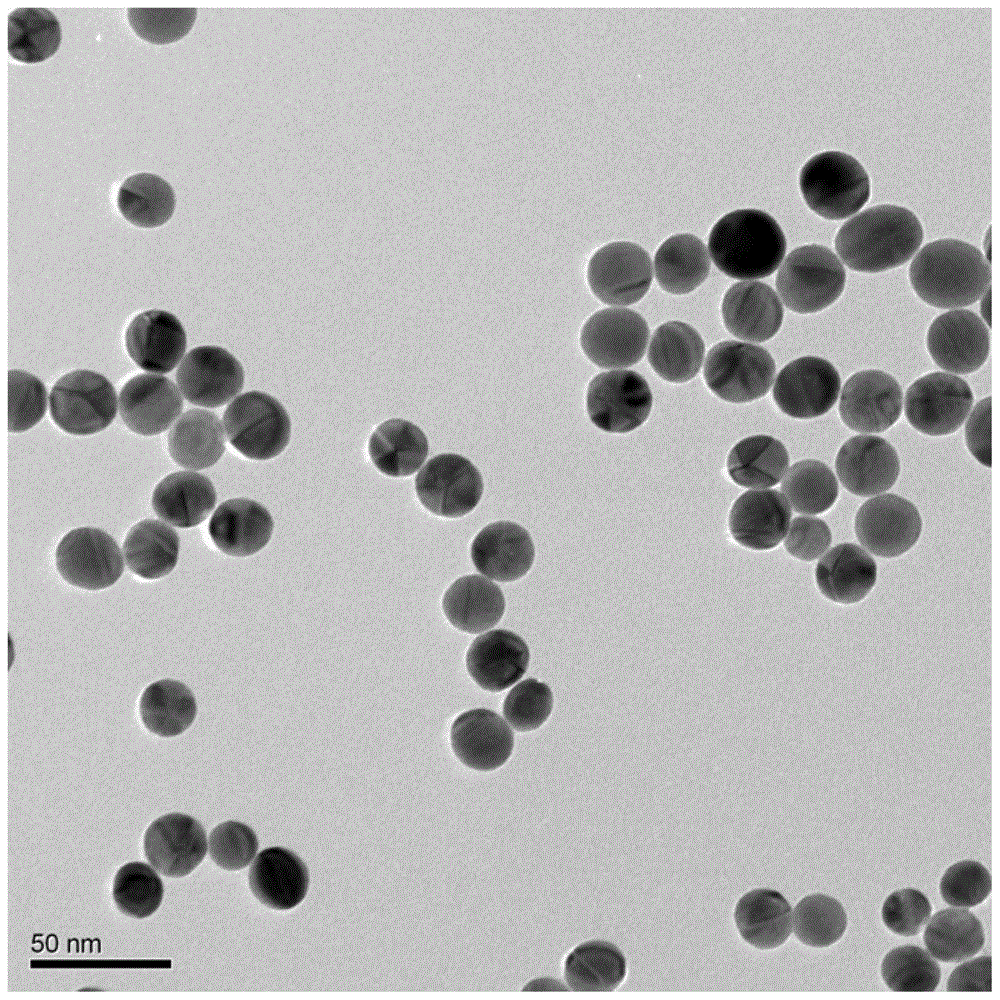

[0026] like figure 1 Shown is a transmission electron microscope image of the Au nanop...

Embodiment 2

[0028] 1) Mix 150 μL trisodium citrate aqueous solution (50 mM), 120 μL AgNO 3 Aqueous solution (1 mM) and 250 μL HAuCl 4 The aqueous solution (20 mM) was added to 19.48 mL of deionized water, and stirred rapidly for 5-10 min to mix the substances evenly to obtain a mixed solution;

[0029] 2) The above mixed solution was placed under a 350W xenon lamp (with a 420nm filter), and irradiated for 1 h while stirring to generate Au nanoparticles in the solution, and then 0.3 mL of trisodium citrate aqueous solution was added to the above solution. (50mM) under a 350W xenon lamp (with a 420nm filter) with stirring, and to this solution was added 0.1mL of AgNO dropwise 3 Aqueous solution (50 mM), after the addition is complete, continue to stir and illuminate for 1 h. Repeat this process 2 times. After the reaction, the Au-Ag core-shell nanoparticles were obtained by post-treatment.

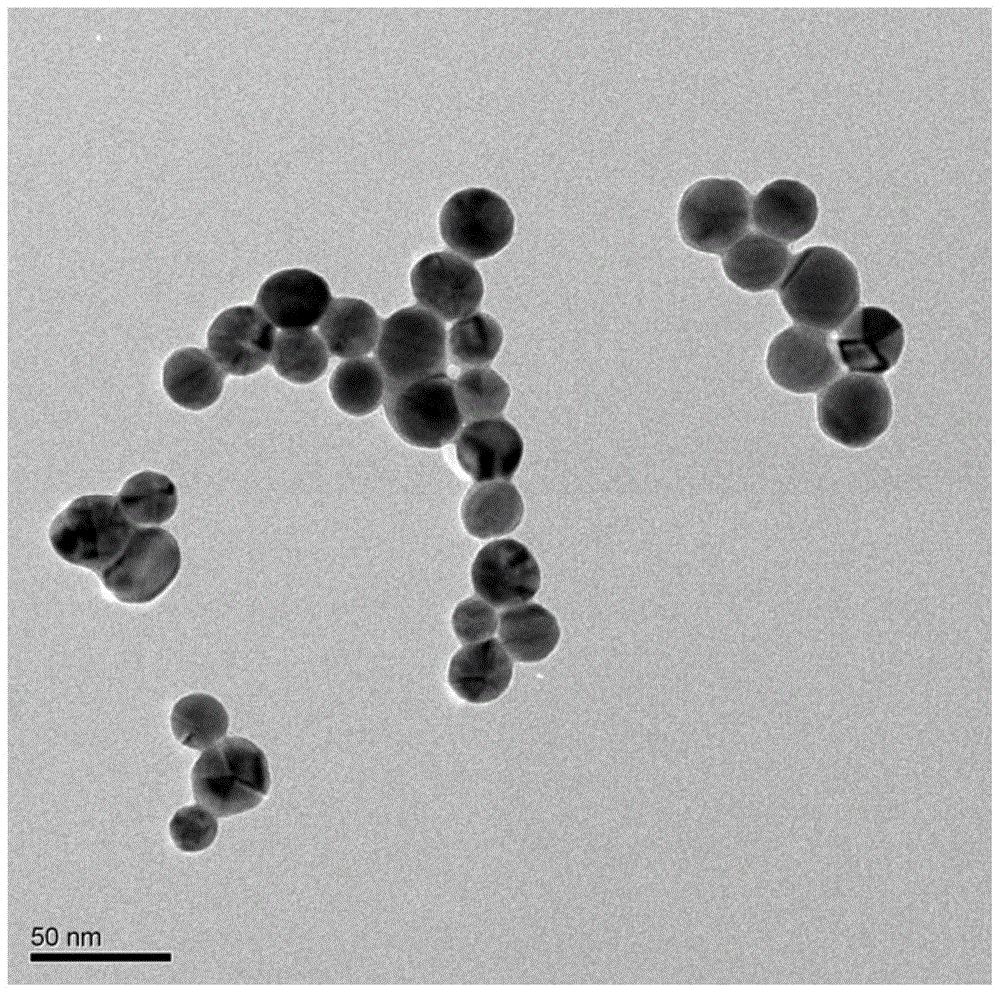

[0030] After testing, the average particle size of the Au nanoparticles prepared in this example...

Embodiment 3

[0033] 1) Mix 150 μL trisodium citrate aqueous solution (50 mM), 120 μL AgNO 3 Aqueous solution (1 mM) and 250 μL HAuCl 4 The aqueous solution (20 mM) was added to 19.48 mL of deionized water, and stirred rapidly for 5-10 min to mix the substances evenly to obtain a mixed solution;

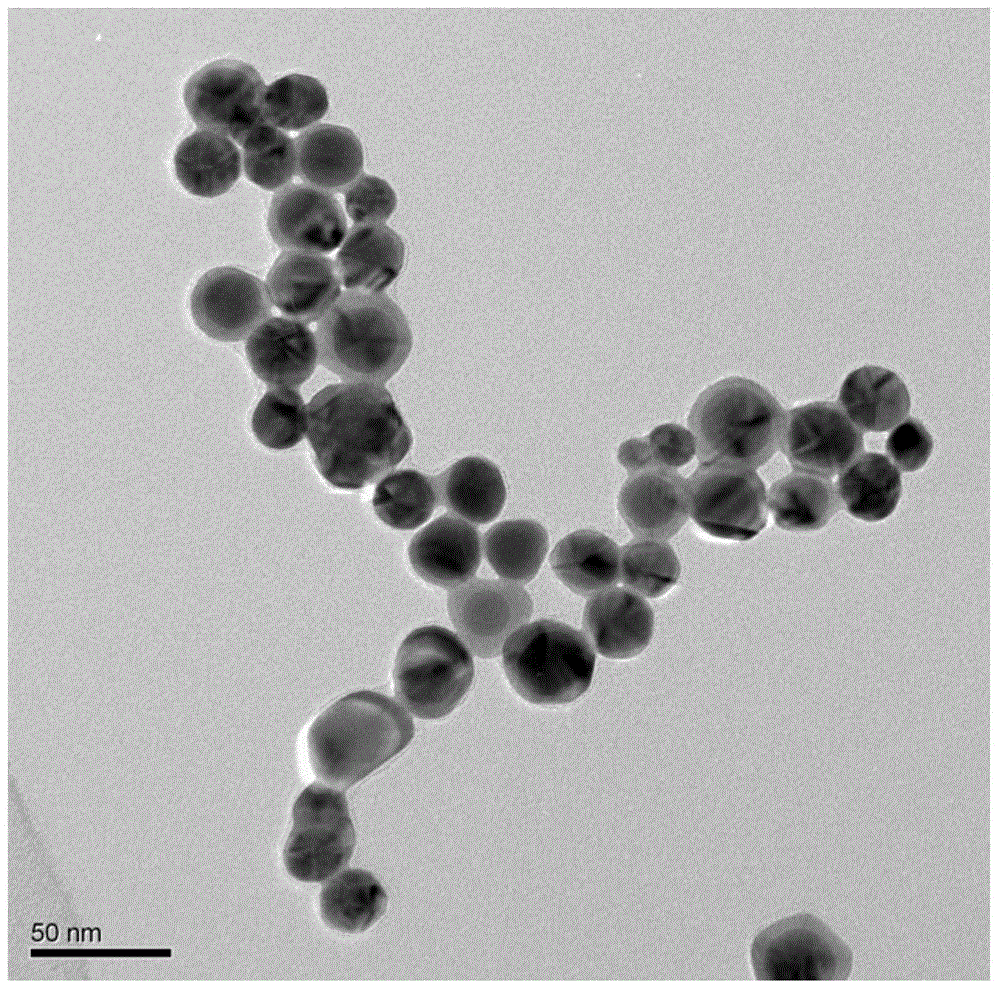

[0034] 2) The above mixed solution was placed under a 350W xenon lamp (with a 420nm filter), and irradiated for 1 h while stirring to generate Au nanoparticles in the solution, and then 0.3 mL of trisodium citrate aqueous solution was added to the above solution. (50mM) under a 350W xenon lamp (with a 420nm filter) with stirring, and to this solution was added 0.1mL of AgNO dropwise 3 Aqueous solution (50 mM), after the addition is complete, continue to stir and illuminate for 1 h. Repeat this process 3 times. After the reaction, the Au-Ag core-shell nanoparticles were obtained by post-processing, and the particle size was about 35 nm.

[0035] After testing, the average particle size of the A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com