Flap ironing and lining, button mounting, and blanking integrated machine

The technology of a pocket cover and an all-in-one machine is applied in the field of garment manufacturing, which can solve the problems of labor consumption, low efficiency, and increased manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

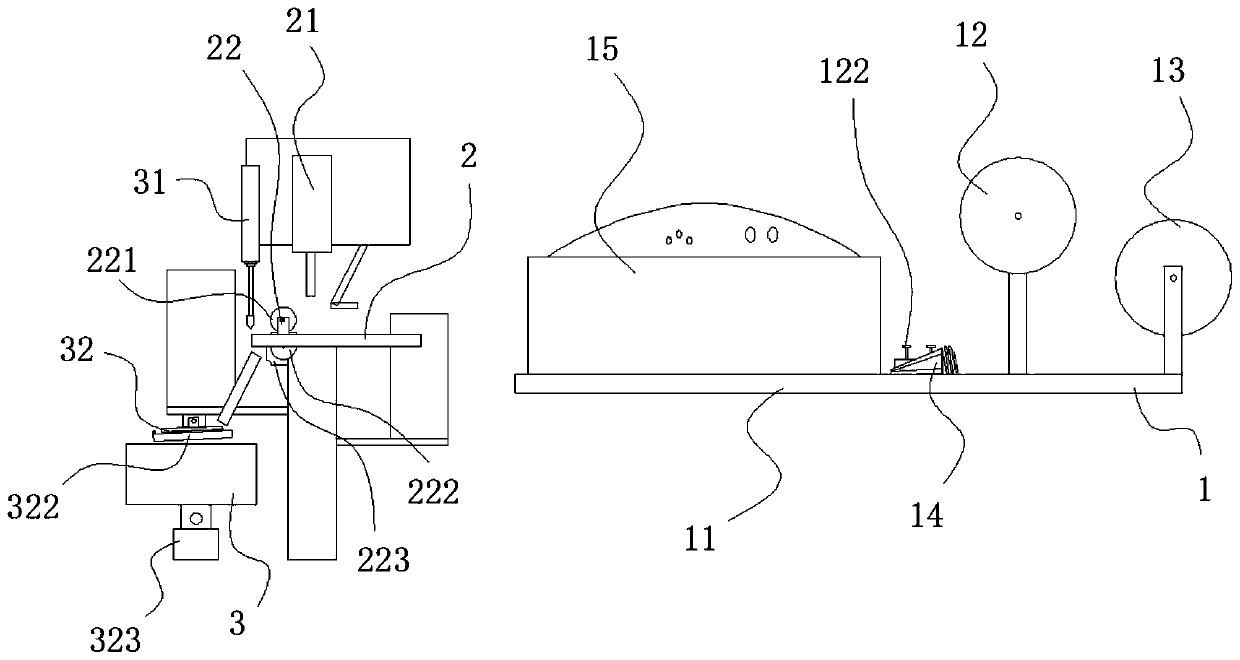

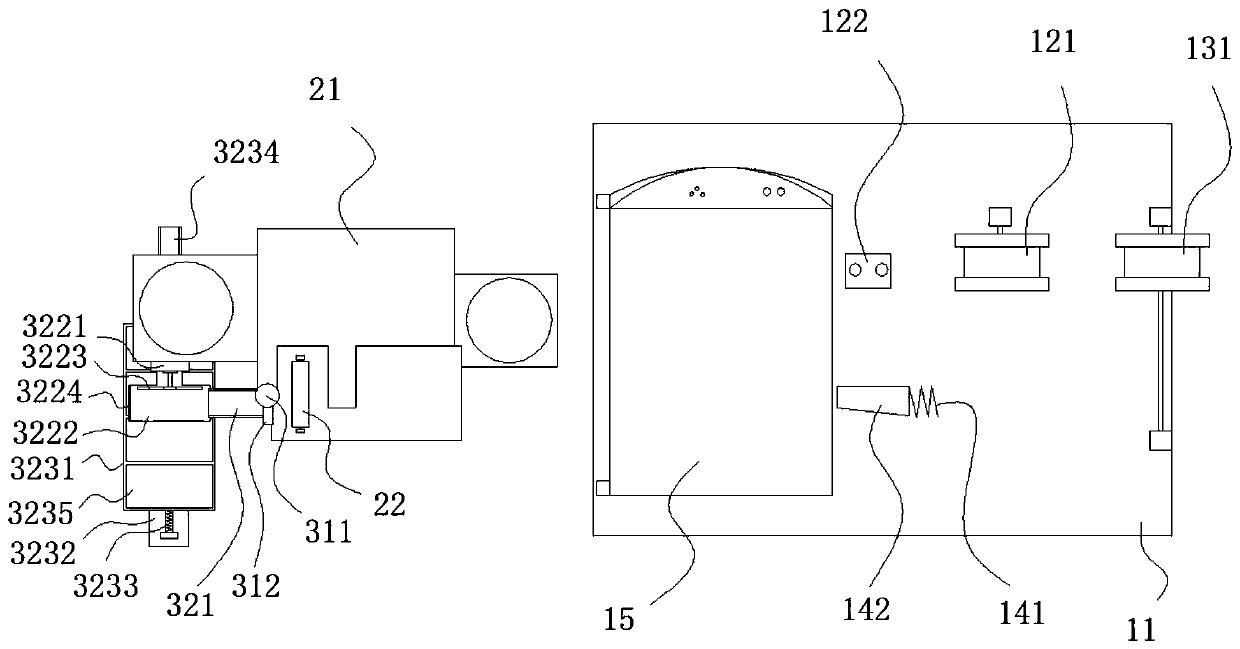

[0025] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach figure 2 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0026] figure 1 It is a structural diagram of an embodiment of an all-in-one machine for pocket flap ironing, lining, copying and button blanking according to the present invention; figure 2 It is a structural diagram of a viewing angle of a preferred embodiment of the present invention. Such as figure 1 with figure 2 As shown, the pocket flap ironing, lining, button copying and blanking integrated machine provided in this embodiment includes: ironing lining mechanism 1, button copying mechanism 2 and blanking mechanism 3, ironing lining mechanism 1, button copying mechanism 2 and blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com