Machining method of duplicate gear

A double gear and processing method technology, applied in the field of mechanical processing, can solve the problems of low processing accuracy, low tooth hardness, inconvenient positioning, etc., and achieve the effects of high processing accuracy, improved overall life, and easy wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

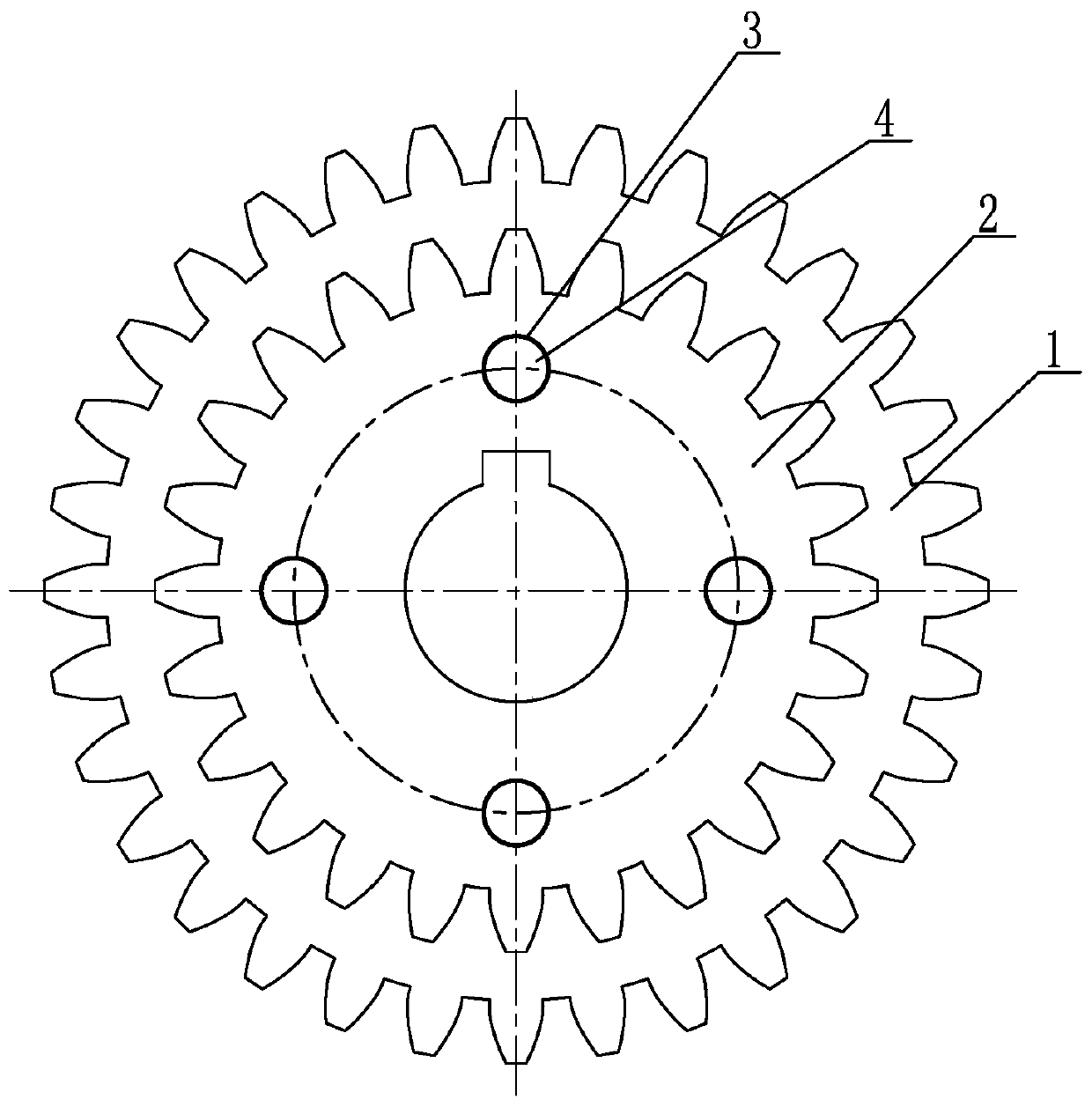

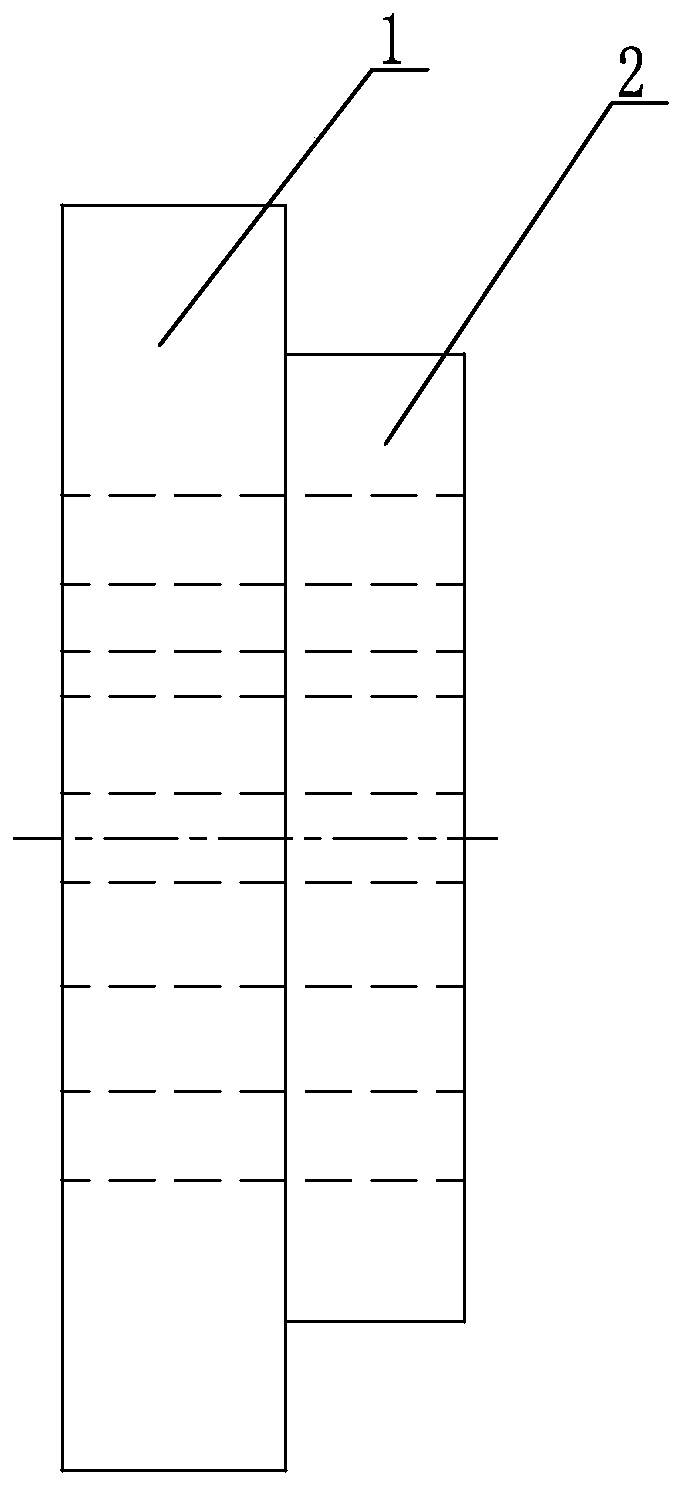

[0019] Specific implementation mode one: combine Figure 1 to Figure 2 Describe this embodiment, the processing method of a kind of dual gear described in this embodiment comprises the following steps:

[0020] Step 1: Forging blanks: select two steel blanks, and forge the blanks separately;

[0021] Step 2: Rough turning: Two blanks are rough turned on a horizontal lathe respectively, the outer circle, end surface and inner hole of the large gear 1 of the double gear are roughly machined, and the outer circle of the pinion 2 of the double gear is roughly machined. For circle, end face and inner hole, 3mm machining allowance is left on each face;

[0022] Step 3: quenching and tempering treatment: heat treat the two blanks to HRC31-35 respectively;

[0023] Step 4: Finish turning: Two blanks are respectively finished turning on a horizontal lathe. During finish turning, a machining allowance of 0.2-0.3 mm is left on each end face of the large gear 1 and pinion 2, and the lar...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination Figure 1 to Figure 2 This embodiment is described. In step six of this embodiment, after the cylindrical pin 4 is assembled in the pin hole 3 , caulking is performed on both sides between the pin hole 3 and the cylindrical pin 4 . The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0031] Such a design makes the two gears fit firmly, the positioning between the two gears is accurate, and the tooth profile is processed after the assembly is completed, so that the processing precision of the gears is high.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination Figure 1 to Figure 2 To describe this embodiment, in the sixth step of this embodiment, the transition fit between the pin hole 3 and the cylindrical pin 4 is performed. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

[0033] This is designed to achieve precise positioning between the bull gear 1 and the pinion 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com