An environmentally friendly mixing equipment for wear-resistant high-performance rubber materials for vehicles

A rubber material, high-performance technology, applied in the field of environmental protection mixing equipment, can solve the problems of low work efficiency, long downtime, poor rubber wear resistance, etc., and achieve the effect of improving work efficiency and high wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

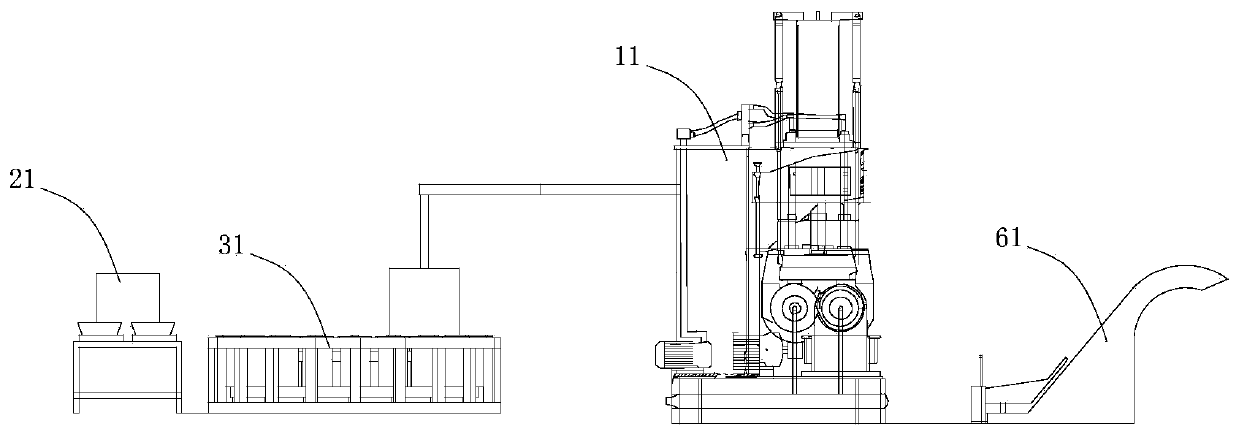

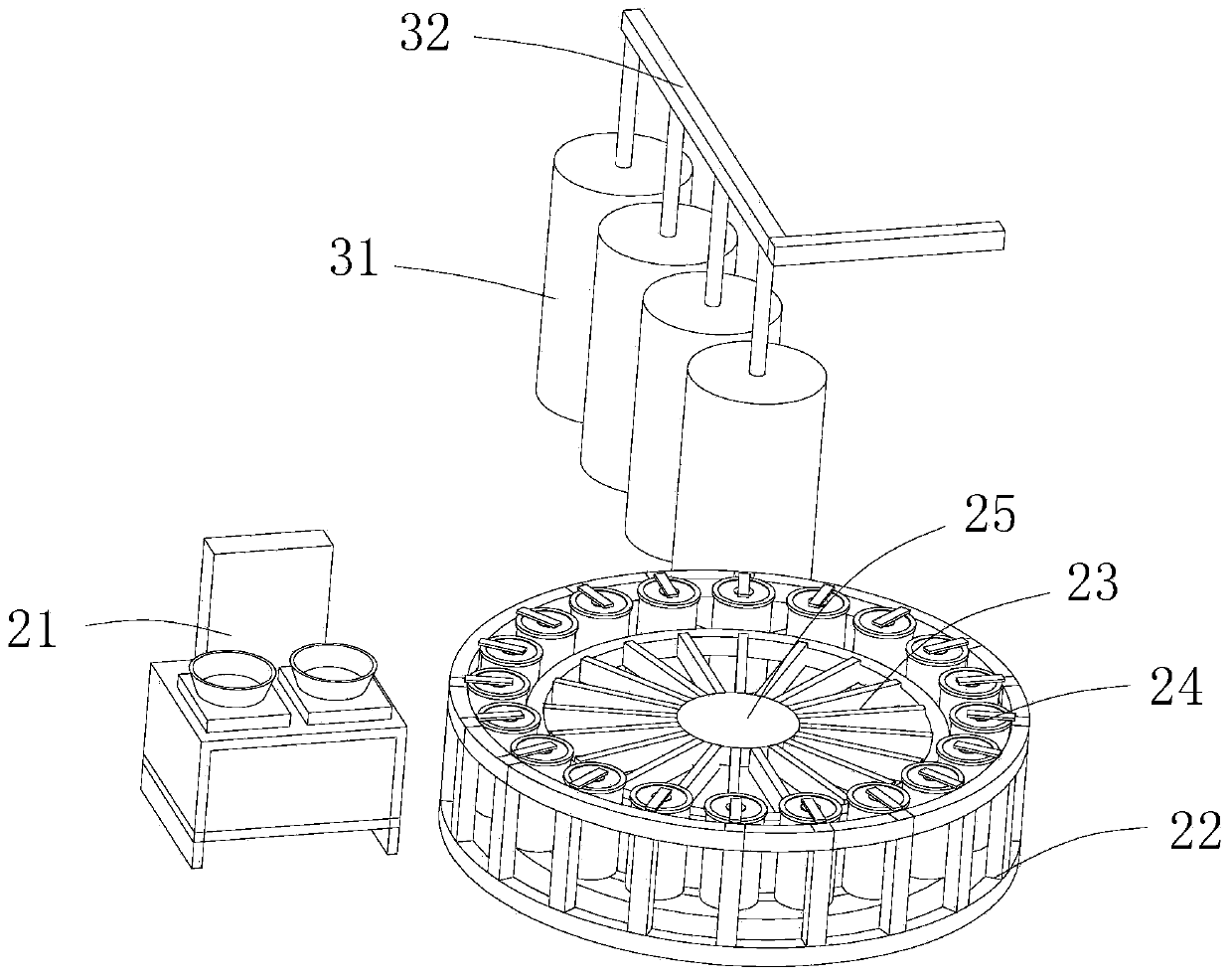

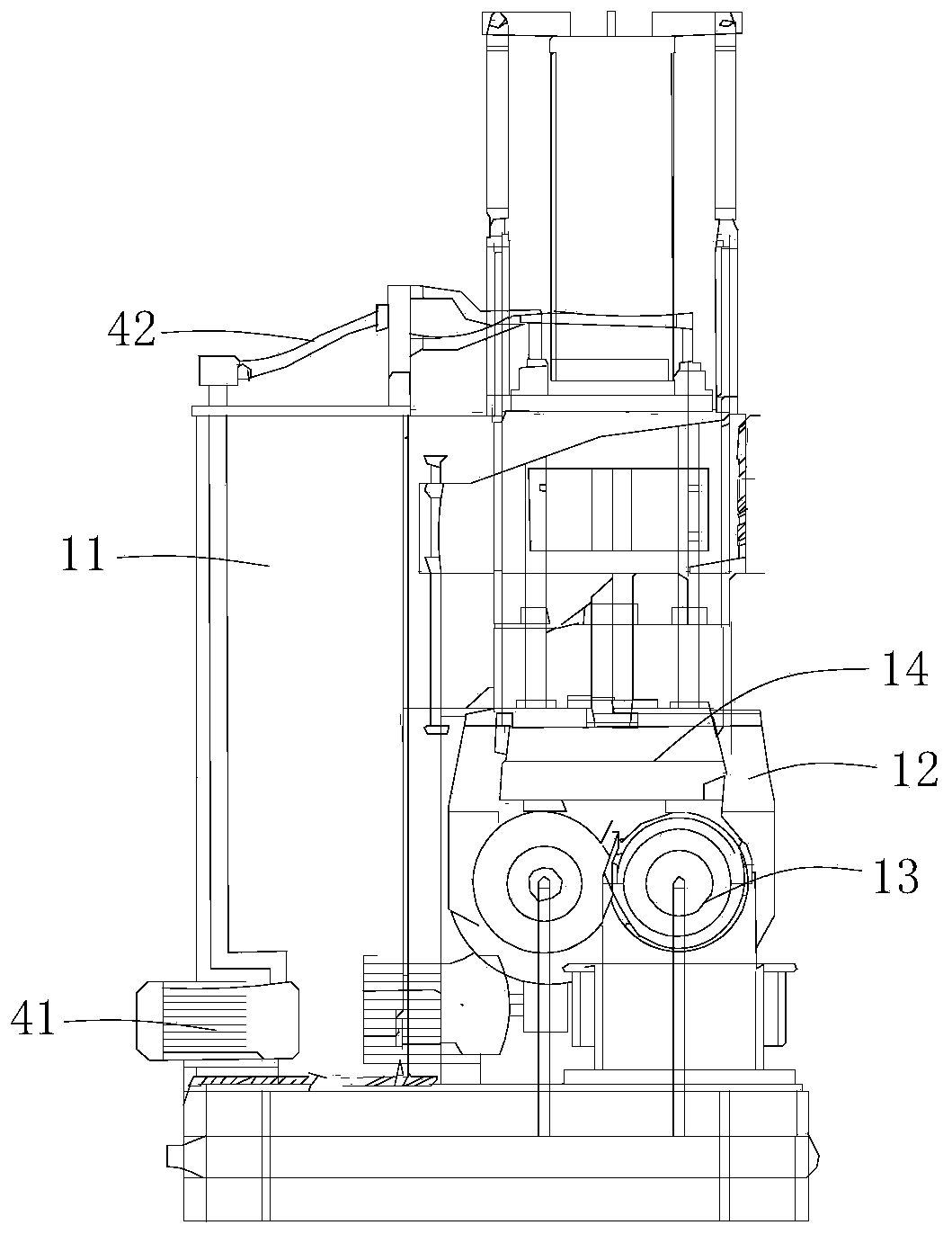

[0033] Such as Figure 1-13 As shown, an environmentally friendly mixing equipment for wear-resistant high-performance rubber materials for vehicles, including a banburying device, a conveying device, a feeding device, and an oil delivery device, wherein the banburying device includes a body 11, a compactor set on the body The mixing chamber 12, the two banburying rollers 13 arranged on the banburying chamber, the opening on the upper part of the banburying chamber, the pressing piece 14 which can move up and down to close the opening, and the pumping device for vacuumizing the banburying chamber. Vacuum parts; the specific structure of the banburying device is prior art, such as the disclosed structure of Chinese patent CN103552167B, no more details; The arc-shaped notch can move up and down under the drive of the cylinder; the pressure piece 14 is provided with a feed hole 141, an oil inlet hole 142 and an air extraction port 143, wherein the feed hole 141 and the oil inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com