Laminated glass with transparent conducting film

A technology of transparent conductive film and laminated glass, which is applied in the direction of windshield, glass/slag layered products, layered products, etc., which can solve the problems of increasing manufacturing cost, prone to hot spots, large heating area, etc., and achieve accurate heating area , avoid waste, the effect of adjustable heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described below in conjunction with the accompanying drawings.

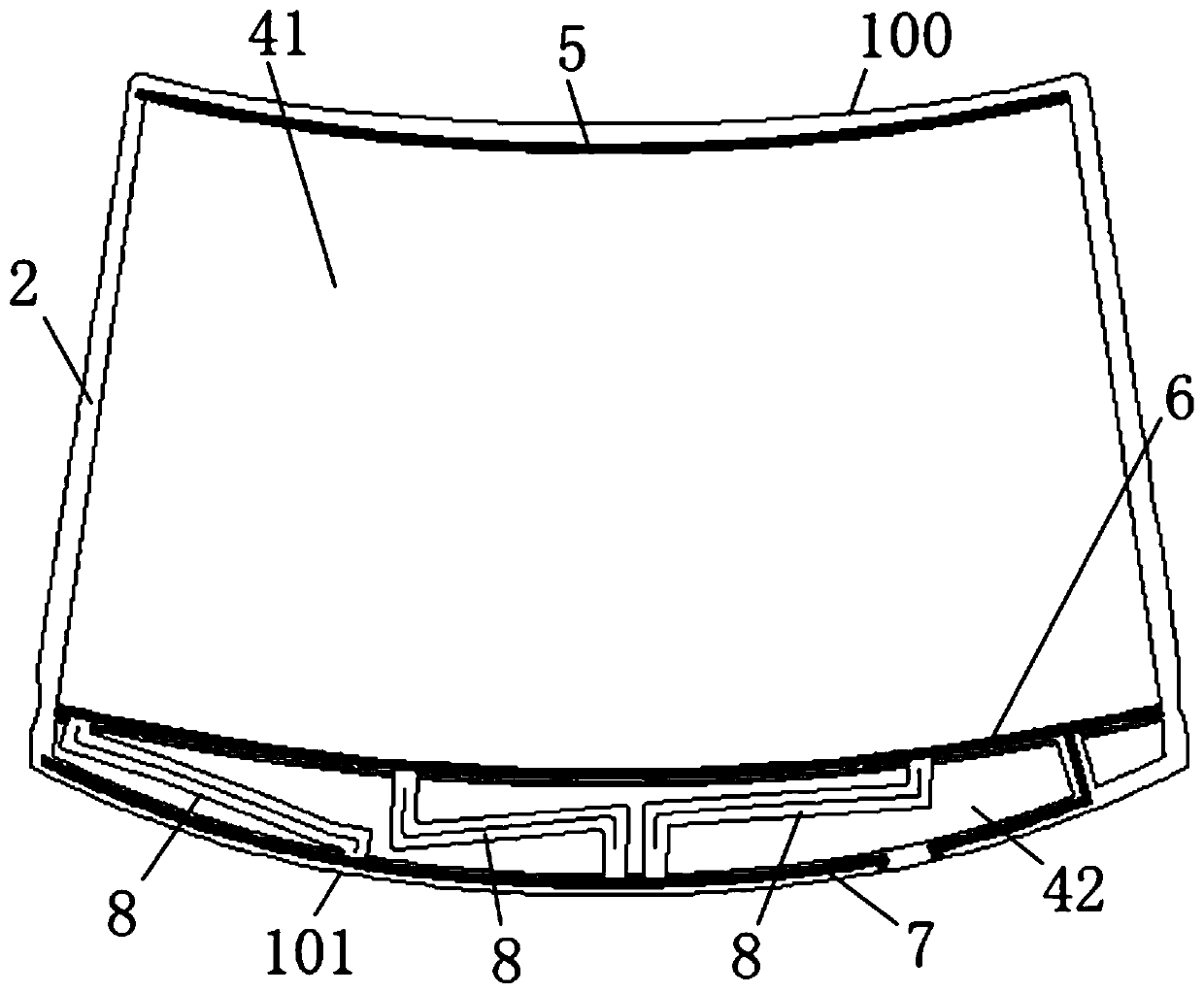

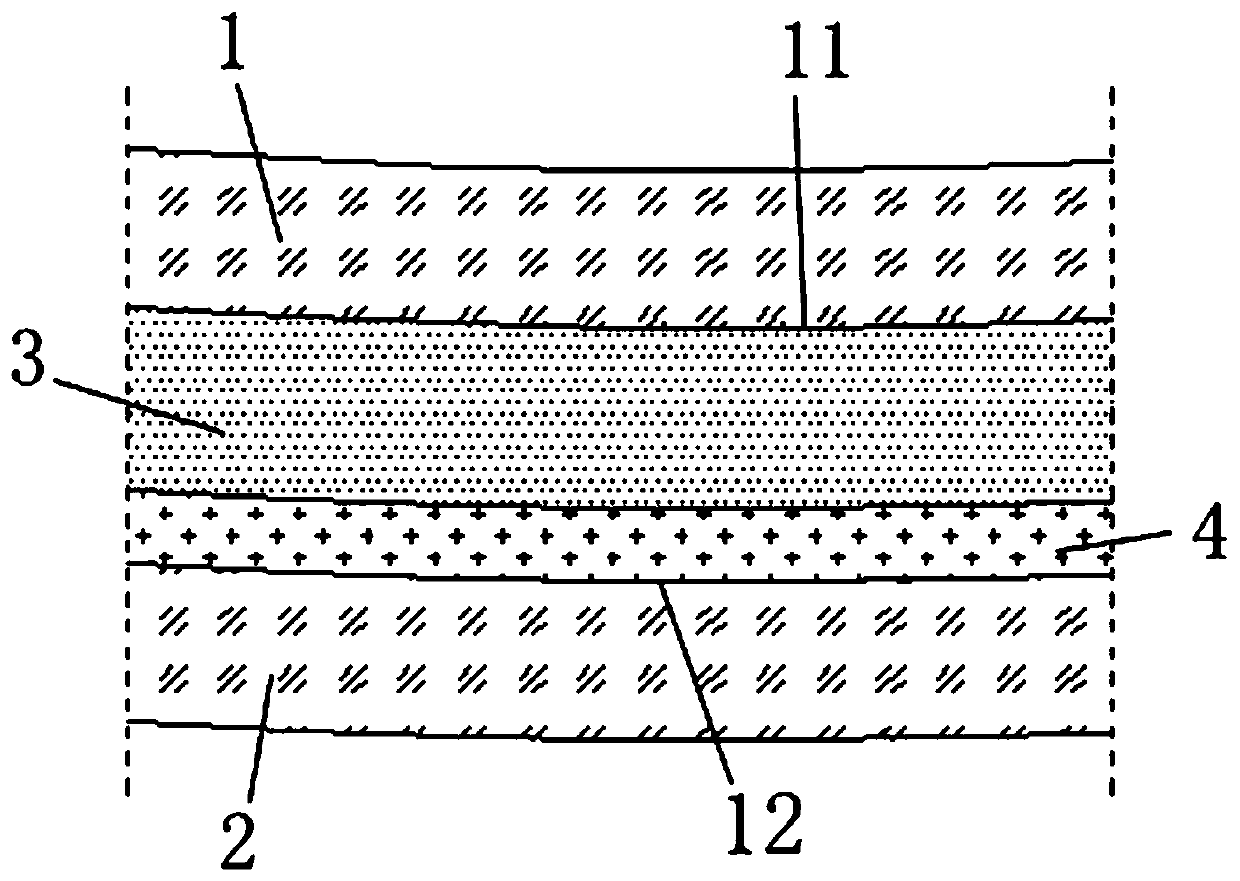

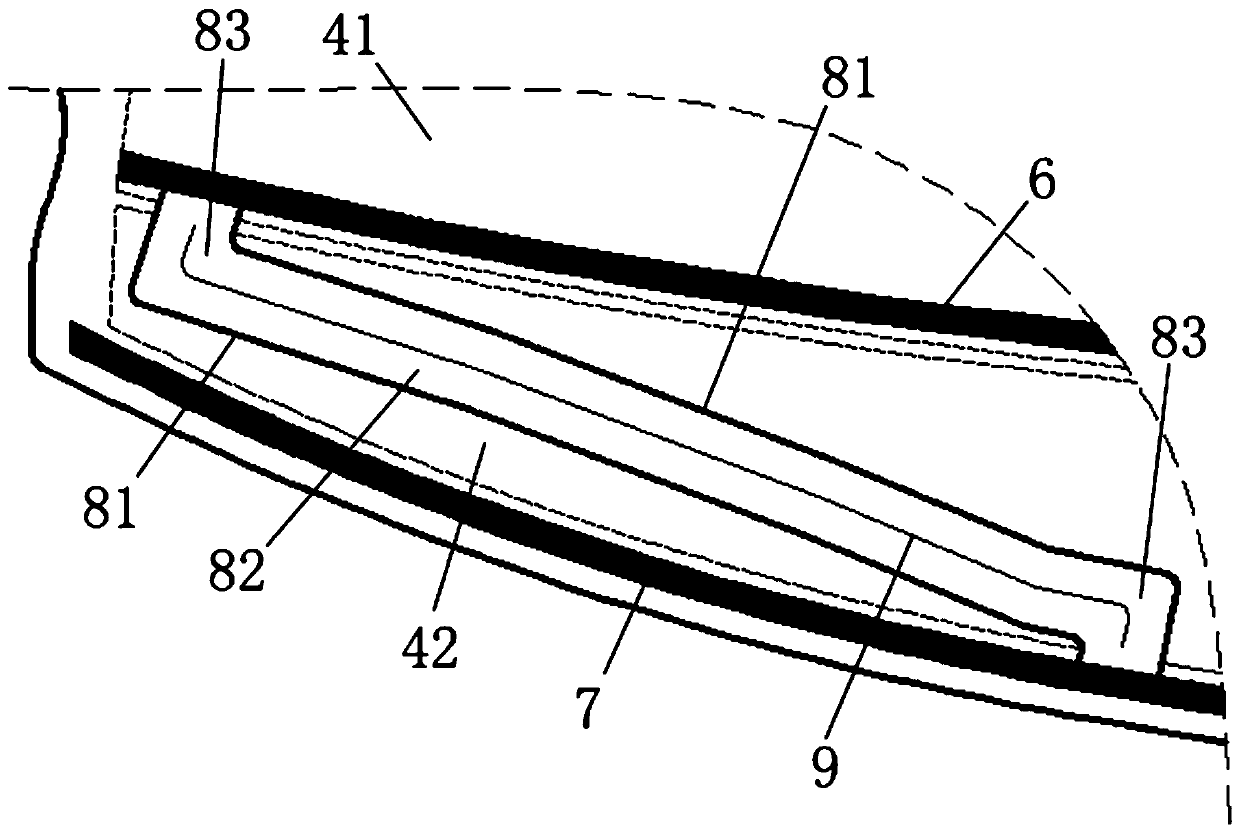

[0021] Such as figure 1 with figure 2 As shown, a laminated glass with a transparent conductive film according to the present invention includes a first curved glass plate 1, a second curved glass plate 2, an intermediate layer 3, and a transparent conductive film 4. The intermediate layer 3 is sandwiched between Between the first curved glass plate 1 and the second curved glass plate 2, the transparent conductive film 4 is deposited on the second surface 12 of the second curved glass plate 2 in contact with the intermediate layer 3; it can be understood that the transparent conductive film The film 4 can also be deposited on the first surface 11 of the first curved glass plate 1 in contact with the intermediate layer 3. At the same time, the transparent conductive film 4 is provided with two first heating zones 41 and a second heating zone 42 that are ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com