Lifting type aircraft sleeper

A sleeping berth and aircraft technology, applied in sleeping berths, aircraft parts, crew accommodation, etc., can solve the problems of low comfort of business seats, large space occupied by business seats, and reduced boarding efficiency, etc., to achieve high comfort of berths , The effect of high boarding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

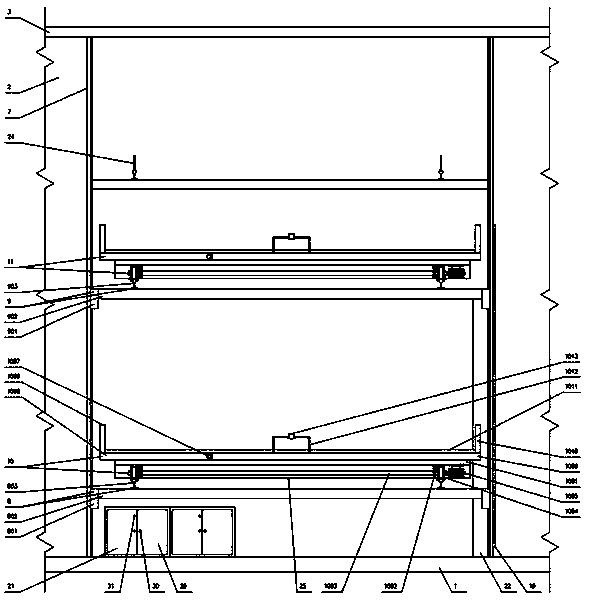

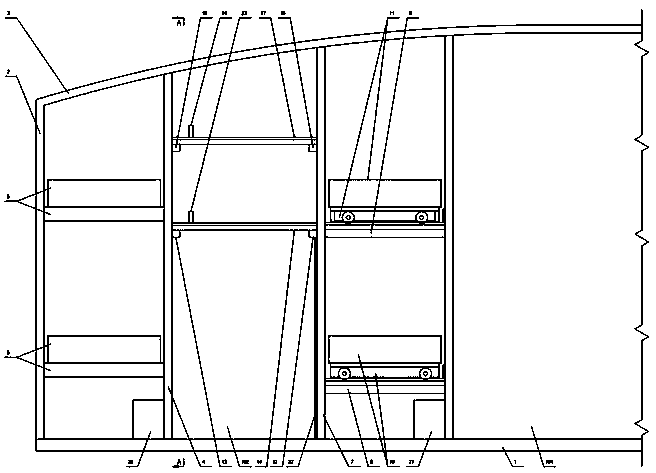

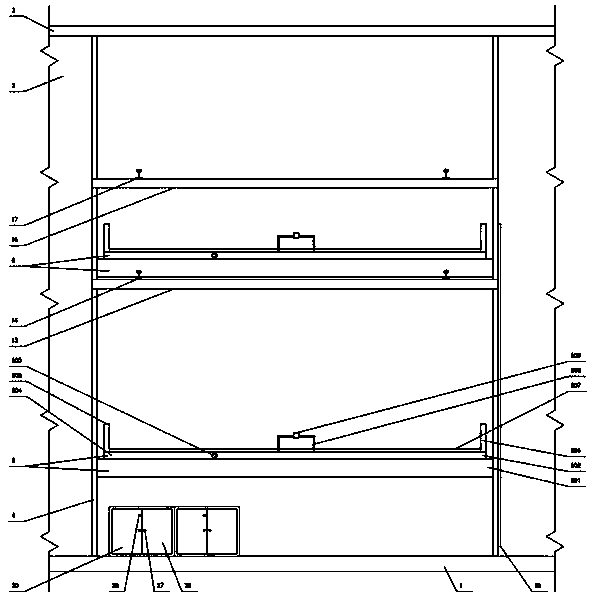

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] refer to Figure 1-5 , a kind of liftable aircraft sleeper according to the specific embodiment, comprising a cabin floor 1, a left side wall of the cabin 2, a cabin top 3, a support arm 4, a sleeper assembly A5, a sleeper assembly A6, a linear motor guide rail 7, and a lifting assembly A8 , lift assembly B9, sleeper assembly C10, sleeper assembly D11, support beam A12, support beam B13, guide rail C14, support beam C15, support beam D16, guide rail D17, the left side wall of the engine room 4. The lower end is fixedly connected to the cabin floor 1. The upper end of the support arm 4 is fixedly connected to the cabin roof 3. A sleeper assembly A5 is arranged between the left side wall 2 of the cabin and the support arm 4. The sleeper assembly A5 includes a frame A501, bed board A502, braking motor A503, bed board B504, bezel A505, bezel B506, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com