Rail rice seedling conveying vehicle

A technology for rail and seedling transportation, which is applied in the field of rail seedling transportation vehicles, which can solve the problems of inconvenient operation, large mechanical volume, and large traction road, and achieve the effects of reducing labor costs, reducing labor intensity, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

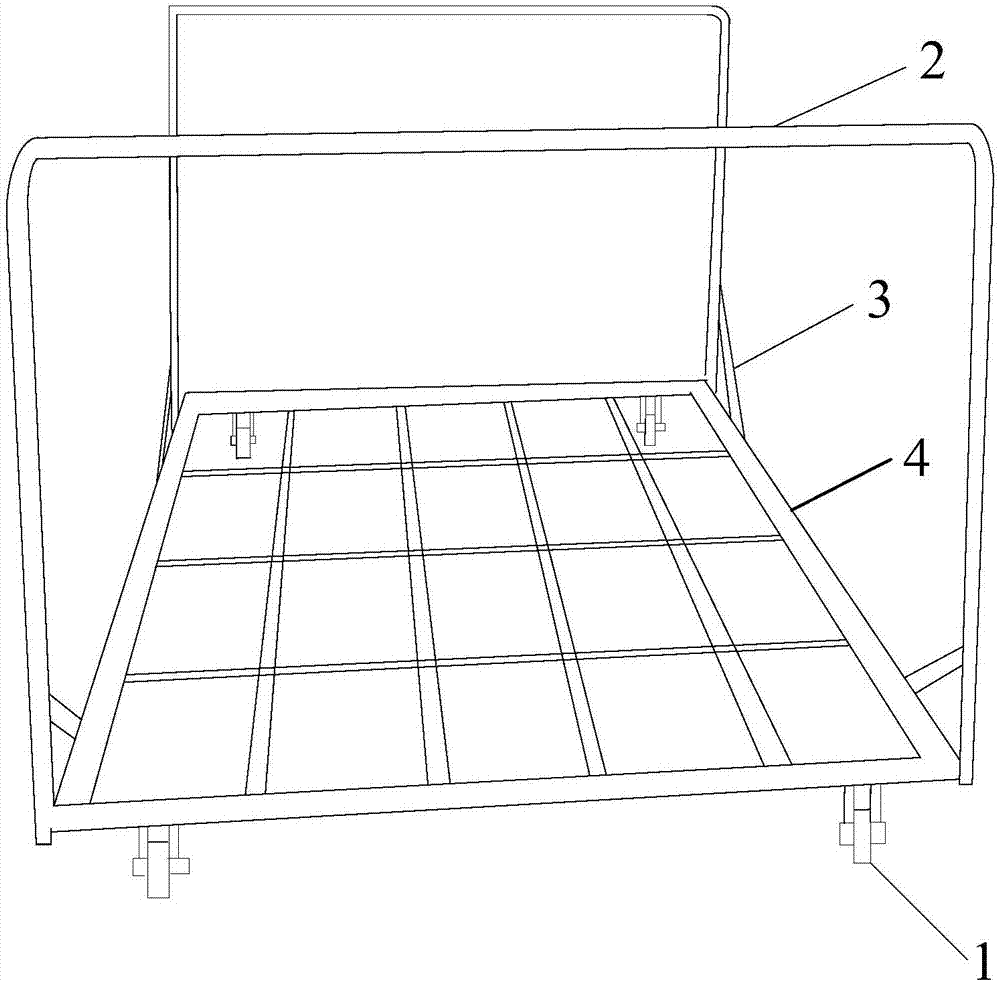

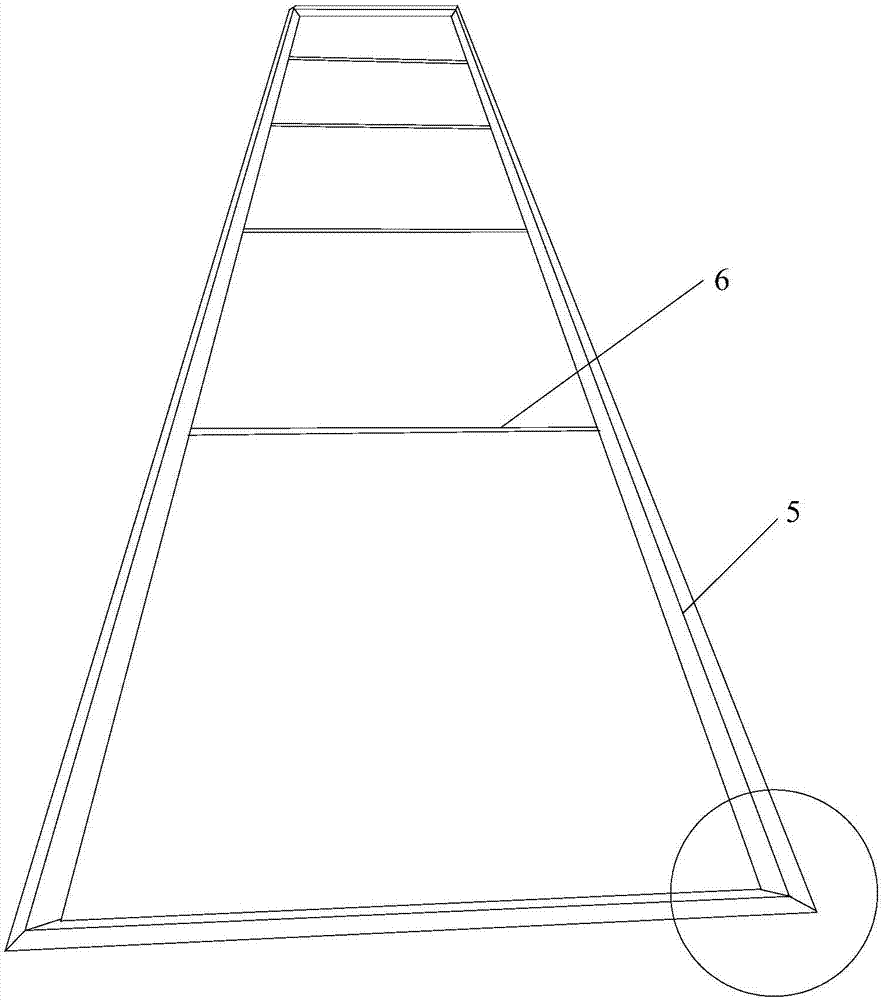

[0023] Please refer to figure 1 , the rail seedling transporting vehicle provided by the present invention comprises the seedling transporting track and the seedling transporting vehicle, and the seedling transporting vehicle comprises a car body 1 and wheels, please refer to figure 2 , the wheel 1 is a concave wheel. Please refer to image 3 , which shows a schematic view of the track structure of the track seedling transporter. Seedling transportation track is made up of two sleepers and the right-angle steel track 5 of laying on each sleeper, and the convex line face of right-angle steel faces upwards, and the convex line of right-angle steel is nested with concave wheel. Please refer to Figure 4 , Figure 4 for image 3 The partial enlarged view of the right-angle steel track in , the convex line refers to the straight line formed by the upward protrusion of the right angle of the right-angle steel. Factors such as the area of comprehensive rice seedling field an...

Embodiment 2

[0027] In order to improve the efficiency of seedling transportation and facilitate the transportation of seedling trays or rice shoots in the muddy environment, the car body can include a push rod 2 with a height of 100cm, which is most in line with human mechanics when promoting. The car body also includes a rice shoot placing base 4, and the wheel 1 is installed below the rice seedling placing base 4, and the push rod 2 is vertically fixed with the rice seedling placing base 4. The length of the seedling placement base platform is 180cm, and the width is 120cm. The length of the seedling placement base platform is 180cm, and the width is 120cm. The seedling placement base 4 can be a base comprising several grid units, and the size of the grid units matches the size of the seedling tray. The seedling placement base designed in this way can ensure that the seedling tray or the seedlings are not easy to fall due to shaking during transportation.

Embodiment 3

[0029] In a muddy environment, when the seedling transport vehicle is also loaded with seedling trays or seedlings, the person pushing the seedling transport vehicle may exert a considerable force on the push rod, which not only directly acts on the push rod 2, but also Through the transmission of the concave wheel, it acts indirectly on the right-angle steel track 5, so in order to prolong the service life of the rail seedling transporter, the rice shoots can also be provided with a push rod reinforcement 3 between the bottom platform 4 and the push rod 2. Several rail reinforcements 6 can also be connected between the right-angle steel rails 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com