Hexane recovery heat exchange method

A thermal method and hexane technology, applied in the field of hexane recovery and heat exchange, can solve the problems of large consumption of low-pressure steam and circulating cooling water, unreasonable energy utilization, low plate efficiency, etc., achieve uniform liquid phase flow, and reduce construction investment. , the effect of improving the efficiency of the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

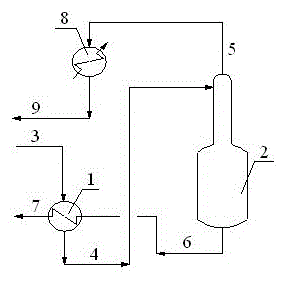

[0016] use figure 1 As shown in the process, the production scale of HDPE is 200,000 tons / year. The water-containing subcooled liquid phase hexane stream 3 enters the hexane liquid phase heat exchanger 1, and after heat exchange, a heated stream 4 is obtained. The stream 4 enters the upper part of the hexane dehydration tower 2, and after separation, the hexane stream 5 containing water is obtained at the top of the tower, and the hexane stream 6 in the hot liquid phase without water is obtained at the bottom of the tower. The stream 6 enters the hexane liquid phase heat exchanger 1, and after exchanging heat with the supercooled liquid phase stream 3, a stream 7 is obtained; the cooled liquid phase hexane stream 7 enters the subsequent process. Wherein, the temperature of hexane stream 3 is 35°C, the temperature of stream 4 is 75°C, the temperature of stream 6 is 90°C, and the temperature of stream 7 is 60°C. The operating temperature of the hexane liquid phase heat exchang...

Embodiment 2

[0019] Same as [Example 1], the production scale of HDPE is 200,000 tons / year, but the operating conditions are changed. The temperature of hexane stream 3 was 45°C, that of stream 4 was 80°C, that of stream 6 was 99°C, and that of stream 7 was 72°C. The operating temperature of the hexane liquid phase heat exchanger 1 is 72° C., and the operating pressure is 0.17 MPaG. The operating temperature of the hexane dehydration tower 2 is 97° C., and the operating pressure is 0.14 MPaG. The operating temperature of the condenser 8 is 64° C., and the operating pressure is 0.37 MPaG.

[0020] By adopting the method of the invention, the consumption of low-pressure steam is reduced by 1.07 tons / hour, the consumption of circulating cooling water is reduced by 135 tons / hour, and the heat exchange area of the reboiler of the hexane dehydration tower is reduced by 32 square meters, thereby reducing construction investment by 11.2%.

Embodiment 3

[0022] Same as [Example 1], the operating conditions are unchanged, but the production scale of HDPE is changed to 300,000 tons / year.

[0023] By adopting the method of the present invention, the consumption of low-pressure steam is reduced by 1.64 tons / hour, the consumption of circulating cooling water is reduced by 207 tons / hour, the heat exchange area of the condenser 3 is reduced by 50 square meters, and the construction investment is reduced by 13.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com