Hot stamping and die cutting assembly line production process

A production process and assembly line technology, applied in metal processing, technology for producing decorative surface effects, decorative art, etc., can solve problems such as low production efficiency, high labor costs, complex processes, etc., to achieve mass production, production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hot stamping die-cutting assembly line production process, including the following steps:

[0033] (1) Coil unwinding;

[0034] (2) Save the paper once;

[0035] (3) Perform a deviation correction on the paper;

[0036] (4) Color mark positioning;

[0037] (5) bronzing;

[0038] (6) Secondary saving of paper;

[0039] (7) Perform secondary deviation correction on the paper;

[0040] (8) Save the paper three times;

[0041] (9) Color mark positioning;

[0042] (10) Die-cut indentation;

[0043] (11) Sheet output.

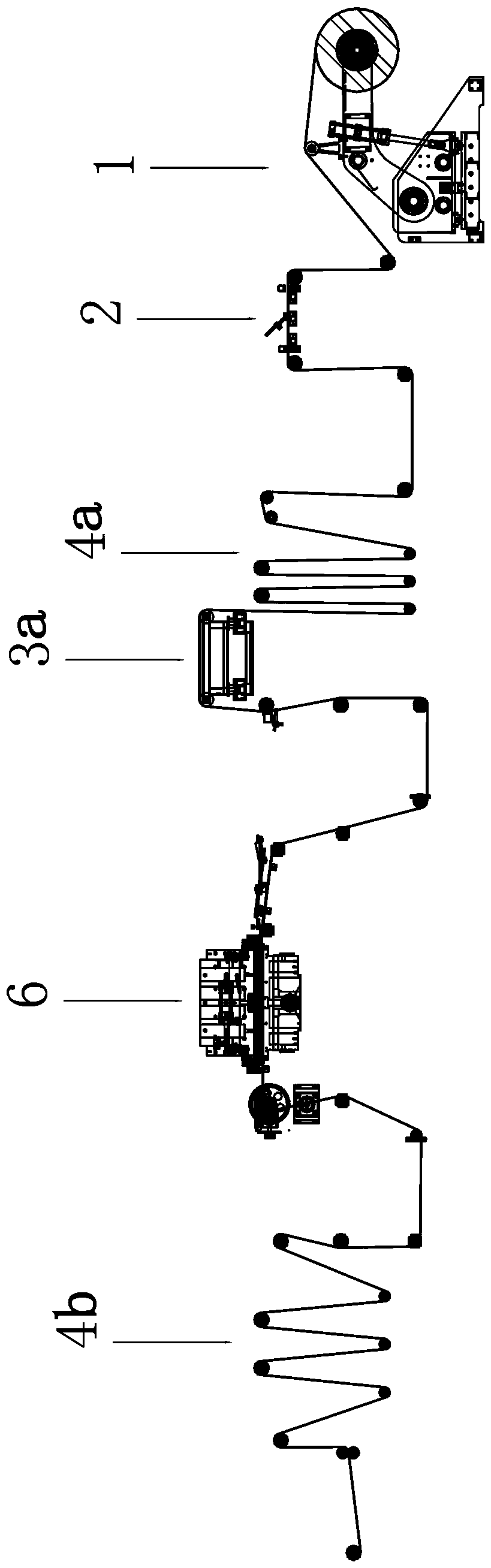

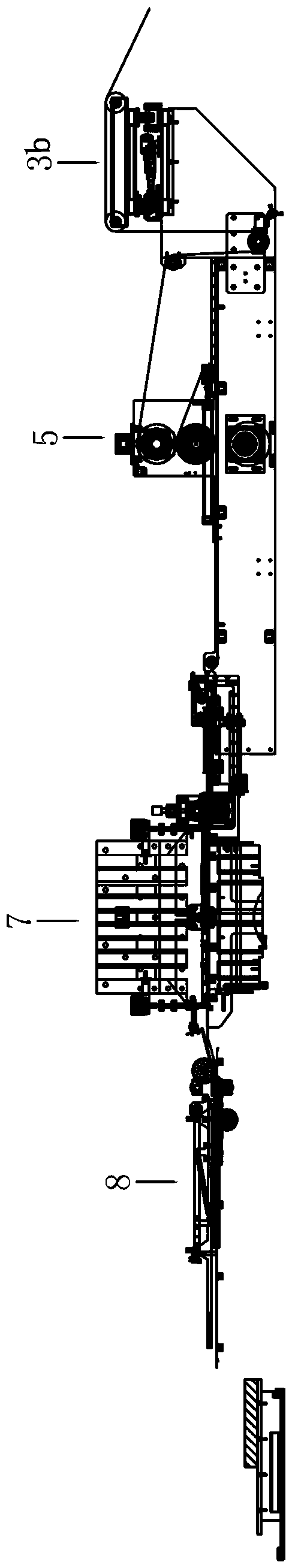

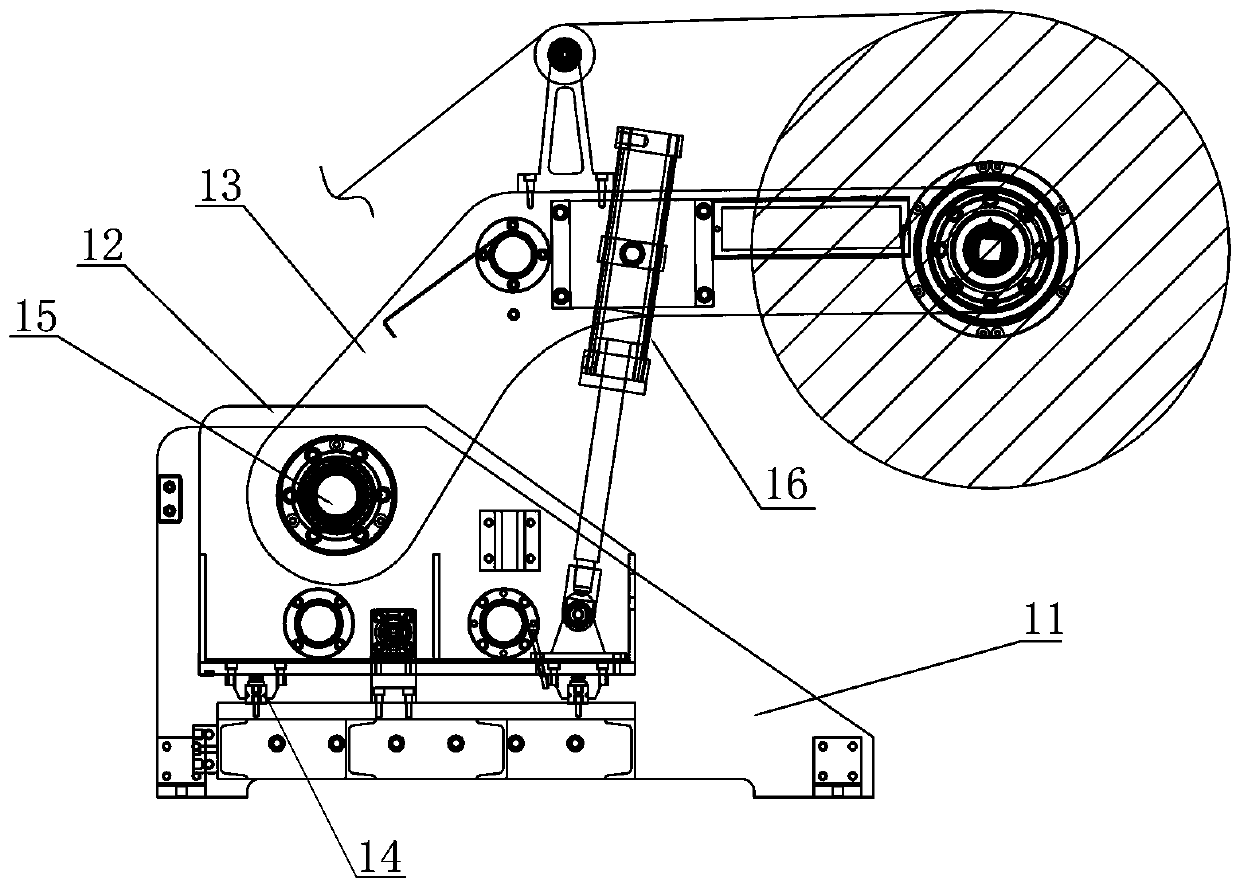

[0044] According to the above-mentioned production process, an unwinding device 1, a preliminary paper feeding device 4, a bronzing device 6, a deviation correction device 3, a paper storage device 5, a die-cutting device 7 and a sheet output device 8 are provided, such as figure 1 and figure 2 shown. Since the bronzing device, the die-cutting device and the sheet output device are all existing structures, they will not be described in detail.

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap