Slag stopping bar feeding device

A technology of feeding device and slag blocking rod, which is applied in the direction of manufacturing converters, etc., can solve the problems of cumbersome slag blocking operation, slag blocking failure, and low success rate, so as to improve the success rate of slag blocking, avoid sticking to steel, and use The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

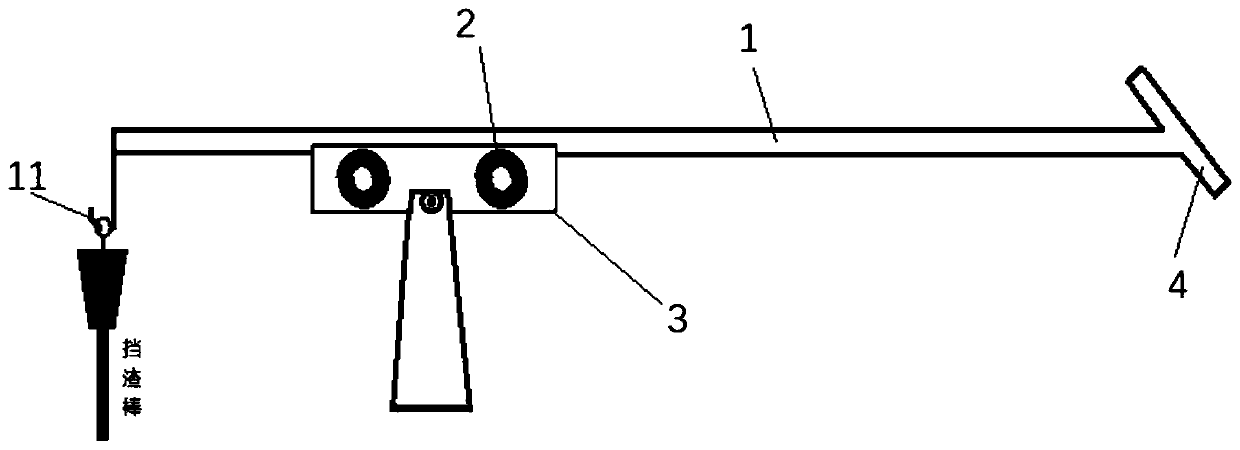

[0030] figure 1 For the schematic structural diagram of a slag blocking stick delivery device provided by the embodiment of the present invention, please refer to figure 1 , the present invention is a kind of slag blocking stick delivery device, the slag blocking stick delivery device is applied to a slag blocking stick, a ring is welded on the thick end of the slag blocking stick, and the slag blocking stick throwing device comprises: a slag blocking stick 1. Guide wheel 2. Support frame 3.

[0031] One end of the slag retaining rod 1 has a hook 11 , and the ring is sleeved on the hook for connecting the slag retaining rod with the slag retaining rod 1 .

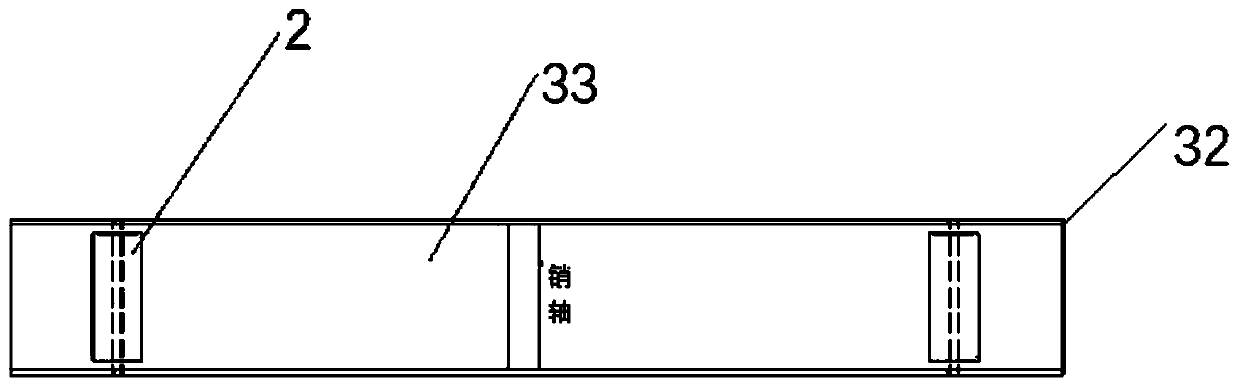

[0032] The guide wheel 2 is slidingly connected with the slag retaining rod 1 for the movement of the slag retaining rod 1 .

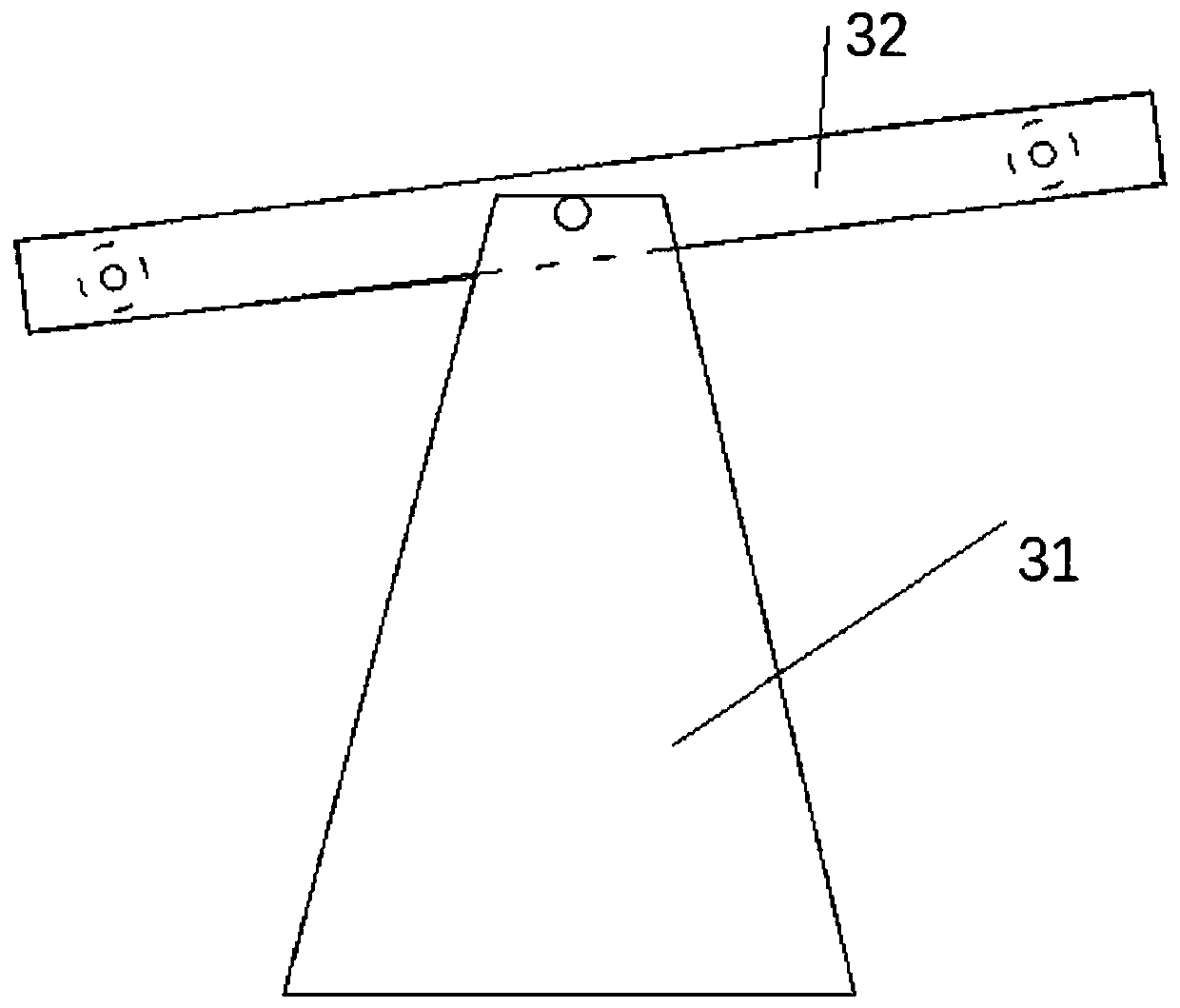

[0033] The support frame 3 is connected to the guide wheel 2, wherein the guide wheel 2 can swing on the support frame 3 to drive the slag retaining rod 1 to swing.

[0034] Specifically, as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com