Multilayer headbox structure for a fiber web machine and method for forming a fiber web

A technology of fiber web machine and fiber web, which is applied in the direction of paper machine, paper machine wet end, textile and paper making, etc. It can solve the problems of liquid layer mixing and fiber web quality reduction, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

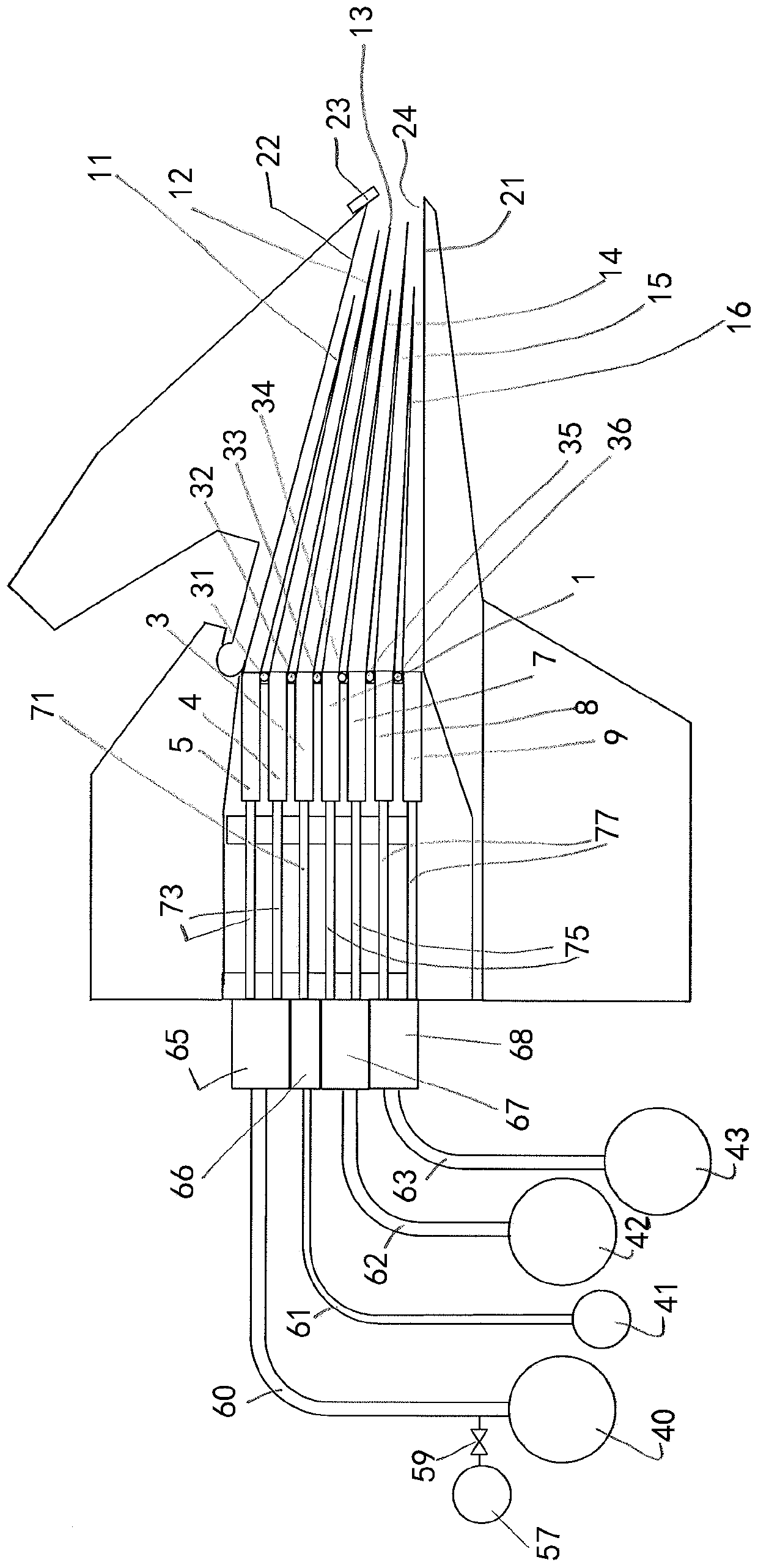

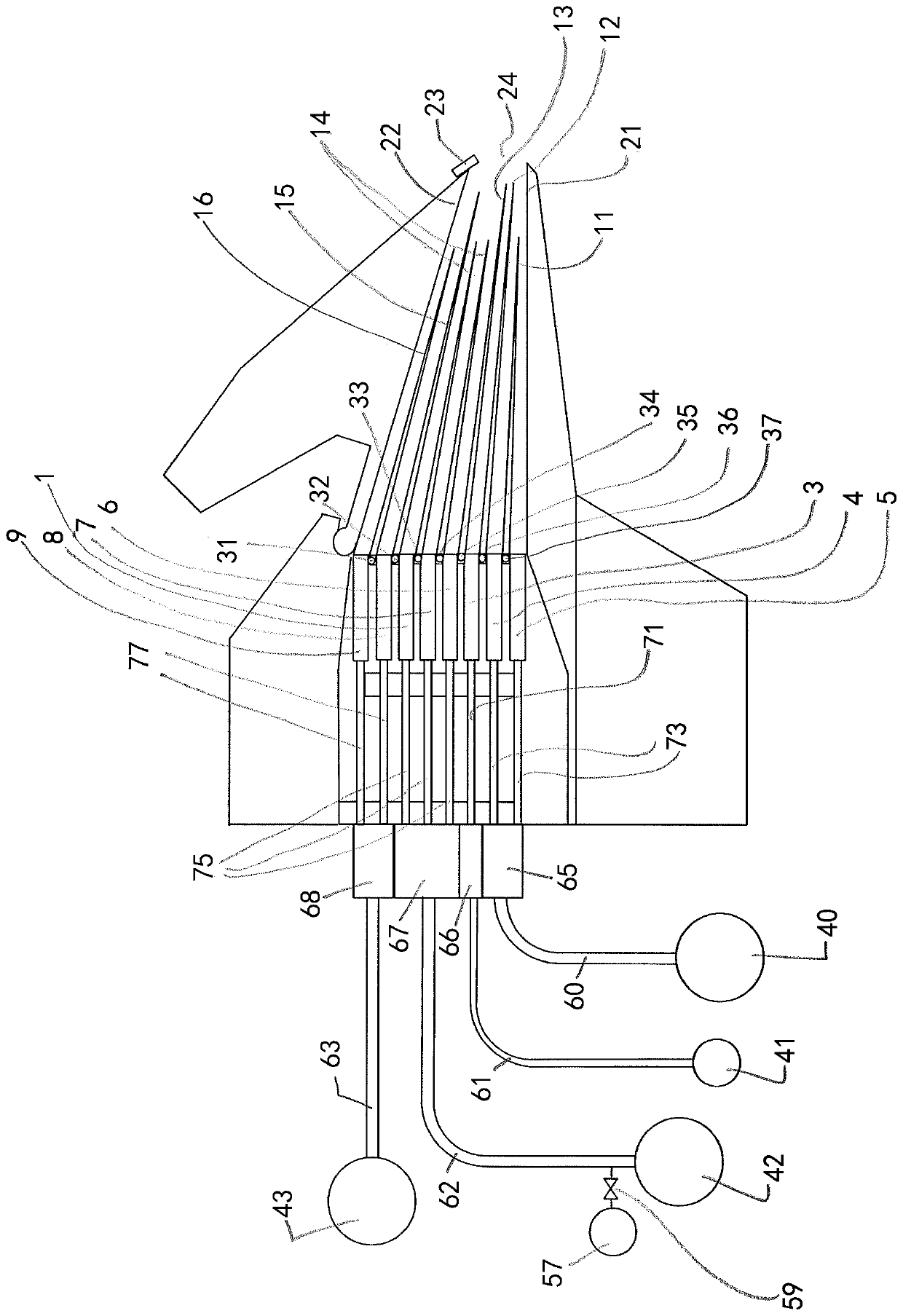

[0035] figure 1 is a cross-sectional view of a multilayer headbox structure according to the invention for a fibrous web machine, such as a paper or board machine, for forming a fibrous web.

[0036] exist figure 1 , from left to right, the headbox comprises stock headers 40, 41, 42, 43, which are arranged at the bottom on the left side in said figure. Liquids such as pulp suspension and water are supplied from the stock feed mains 40, 41 , 42, 43 via manifolds 60, 61 , 62, 63 serving as supply means into the intermediate chambers 65, 66, 67, 68 respectively.

[0037] Optionally intermediate chambers 65, 66, 67, 68 are provided as balancing chambers. That is, the stock feed manifolds 40, 41, 42, 43 may be directly or integrally connected to the headbox.

[0038] Furthermore, a diffuser chamber is provided, in which diffuser pipes 1, 3, 4, 5, 7, 8, 9 are arranged as diffusers, and a nozzle chamber with converging walls forming a weir opening (nozzle outlet) 24 21, 22. Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com