Explosion-proof switch cabinet and explosion-proof method of switch cabinet

An explosion-proof switch and cabinet technology, applied in the field of switch cabinets, can solve the problems of high explosion-proof pressure and the explosion-proof effect needs to be improved, and achieve the effects of slowing down the rising rate, reducing the pressure rising rate and reducing the explosion scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

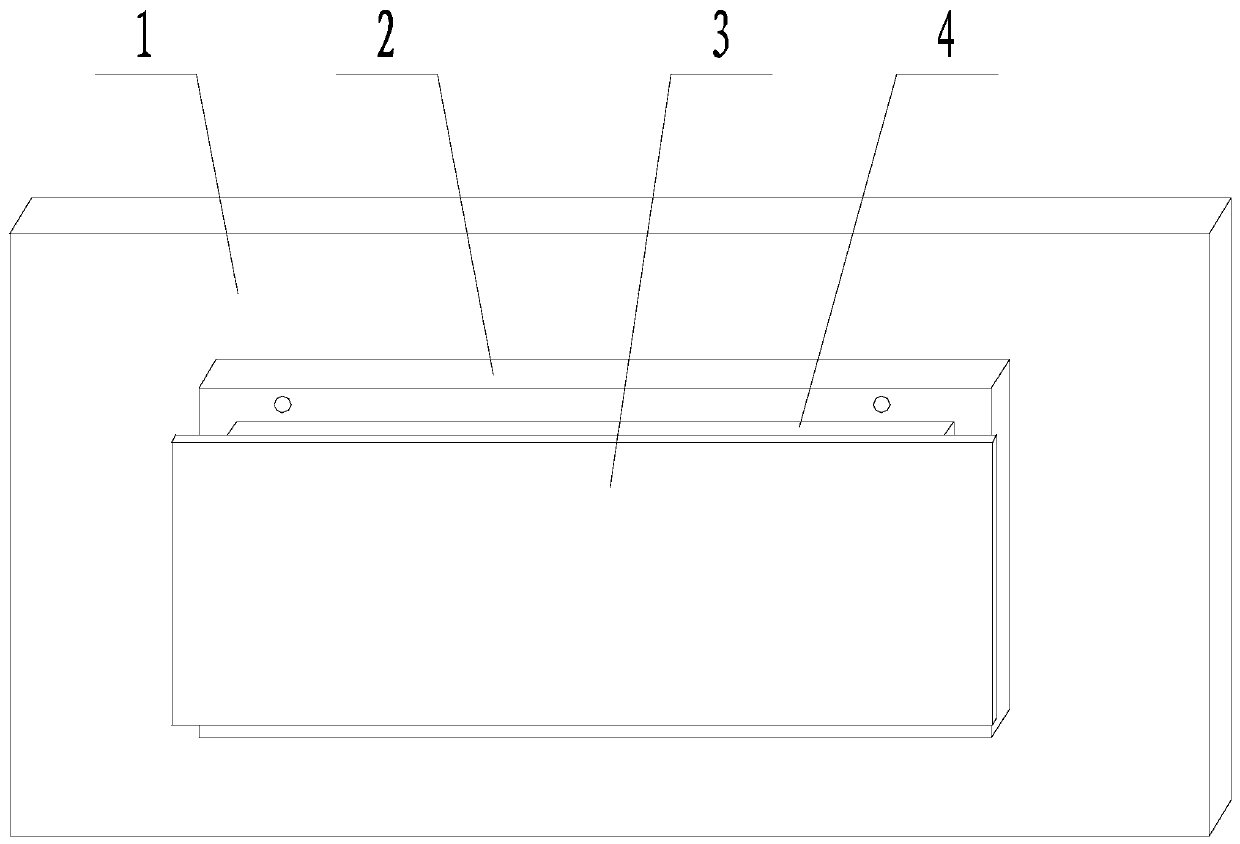

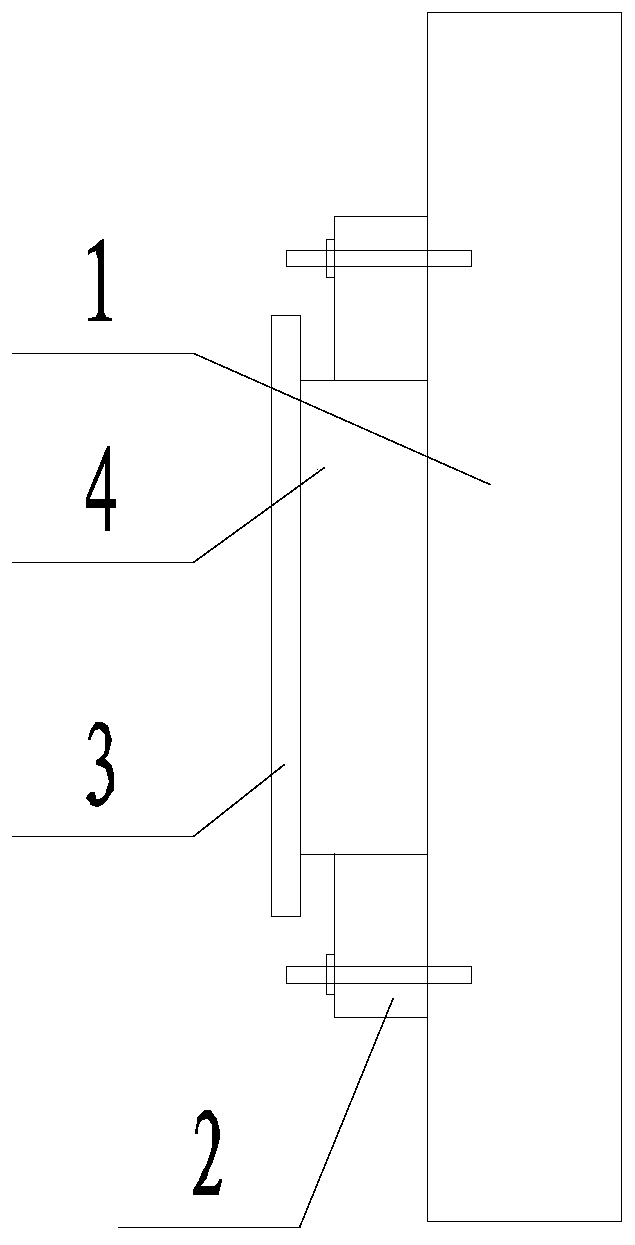

[0033] like figure 1 and figure 2The shown explosion-proof switch cabinet includes a cabinet body 1 and an energy absorbing device fixed on the inner wall of the cabinet body 1. The energy absorbing device includes a frame 2, a partition 3, and foamed aluminum 4. The frame 2 is fixed On the inner wall of the cabinet body 1, the outer profile of the foamed aluminum 4 matches the inner profile of the frame 2, and the foamed aluminum 4 is stuffed into the frame 2, wherein the thickness of the foamed aluminum 4 is greater than that of the frame 2 Thickness; the partition 3 is fixed on the side surface of the foamed aluminum 4 facing the inside of the cabinet body 1 .

[0034] When the switchgear is working normally, the energy absorbing device will not cause any interference to the switchgear in the cabinet. When the temperature inside the cabinet rises and the pressure rises rapidly, the increased air pressure will act on the foamed aluminum, and the foamed aluminum will Under...

Embodiment 2

[0036] On the basis of Example 1, one side surface of the foamed aluminum 4 is attached to the inner wall of the cabinet body 1, and the other side surface is attached to the partition 3; the projection of the foamed aluminum 4 on the surface of the partition 3 is completely Fall into the area where the partition 3 is located. The separator 3 is a galvanized steel plate. The energy absorbing device is fixed on the inner side wall of the cabinet body 1 and the inner side surface of the cabinet door of the cabinet body 1 . The foamed aluminum 4 is soldered to the separator 3 or bonded by an adhesive. In the brazing connection process, it is necessary to use a vacuum welding process or a nitrogen protection process, and use Al-Si solder as an intermediate layer. After the welding is completed, the temperature is kept at 585-600° C. for 5-15 minutes. In this embodiment, the frame 2 and the cabinet body 1 are fixedly connected by bolts.

[0037] The performance of the aluminum f...

Embodiment 3

[0045] On the basis of any of the above-mentioned embodiments:

[0046] preferred, such as Figure 4 As shown, the partition 3 extends as a cover covering the inner wall of the cabinet body 1 .

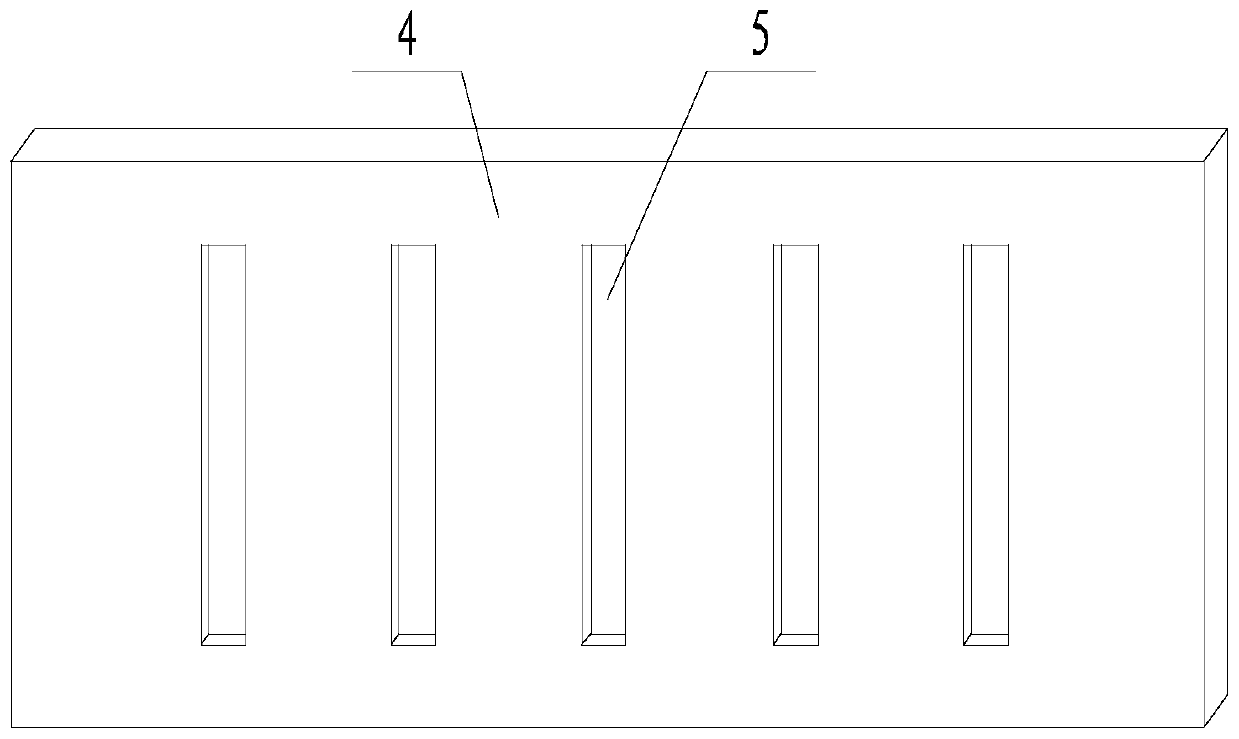

[0047] preferred, such as image 3 As shown, the foamed aluminum 4 is provided with a plurality of parallel grooves 5 on one side surface facing the inside of the cabinet body 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com