Device for heat dissipation and heat dissipation monitoring of motor controller

A motor controller and monitoring device technology, applied in electrical components, electrical equipment structural parts, cooling/ventilation/heating renovation, etc., can solve the problems of lack of effective heat dissipation monitoring feedback, no monitoring, etc., to ensure uniform heat dissipation and Stability, increase heat dissipation effect, choose flexible and diverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

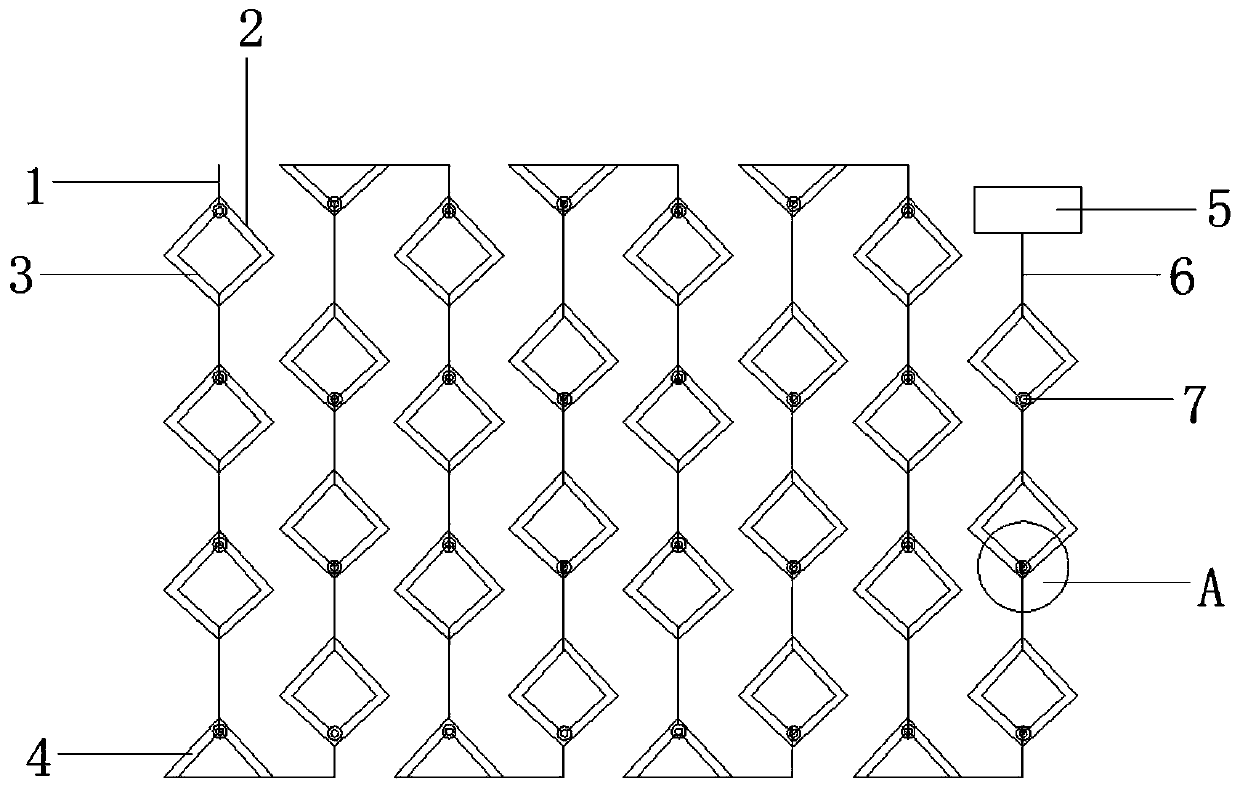

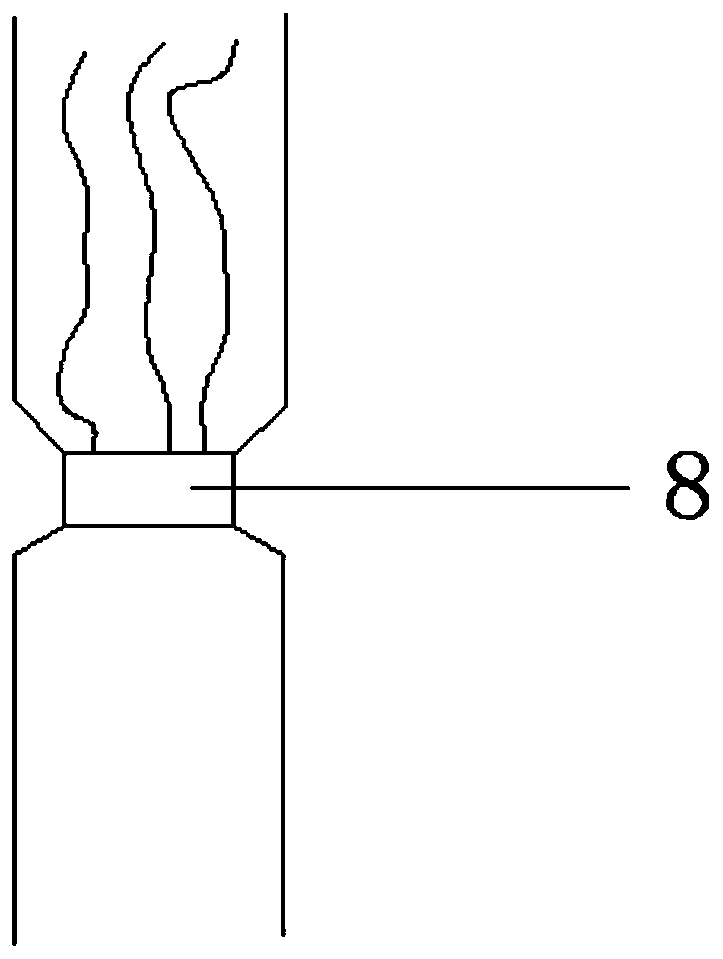

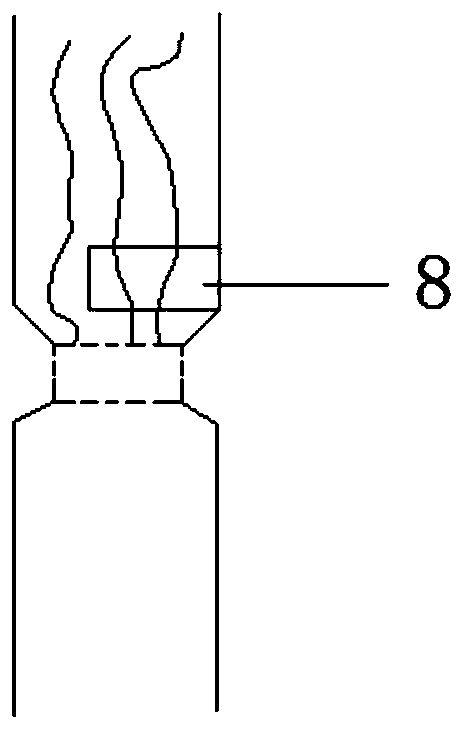

[0025] Such as Figure 1-4 As shown, a heat dissipation and heat dissipation monitoring device that can be used for a motor controller includes a cooling channel inlet 1, and the cooling liquid can be made of the best cost-effective material according to different heat dissipation requirements. The bottom of the cooling channel inlet 1 is connected to a first cooling channel 2 , the second cooling channel 3, the first cooling channel 2 is set to a normally open state, the material can be silver, iron, aluminum, etc., and whether to increase the microstructure can be determined according to the heat dissipation requirements, and the second cooling channel 3 is set as In the normally closed state, the first cooling passage 2, the second cooling passage 3 and the edge connection are connected by a triangular ring structure 4, and a magnetic block 8 is arranged in the second cooling passage 3, and the magnetic block 8 is a magnetic The variable material block is used to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com