A kind of multi-layer heat-conducting photovoltaic backplane material

A photovoltaic backplane and concentrated solution technology, applied in photovoltaic power generation, semiconductor devices, electrical components, etc., can solve the problems of low thermal conductivity of polymer materials, inability to effectively dissipate heat, difficult to meet the 25-year lifespan, and affecting the stability of packaging materials. , to achieve the effect of ensuring uniform heat conduction, good heat conduction, and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

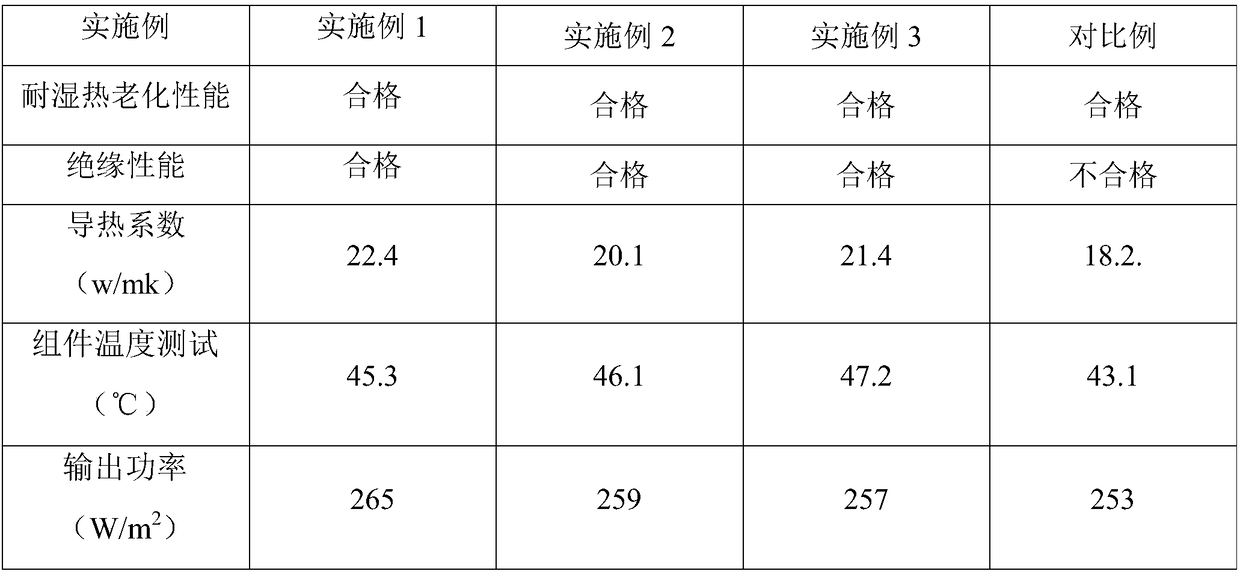

Examples

Embodiment 1

[0022] A kind of multi-layer heat conduction type photovoltaic backplane material, its steps are as follows:

[0023] Step 1, adding graphene powder into absolute ethanol, adding polyvinylpyrrolidone and ultrasonically stirring to form a uniform suspension;

[0024] Step 2, adding foaming agent and filler to the uniform suspension to obtain a mixed solution, and then performing vacuum distillation for 10 minutes to obtain a concentrated solution;

[0025] Step 3, adding deionized water to the concentrated solution, ultrasonically stirring evenly, and performing a second vacuum distillation for 30 minutes to obtain a thermally conductive suspension;

[0026] Step 4, cleaning the ultra-thin aluminum sheet, immersing and pulling it for 1 hour, sealing, heating and pressurizing for 1 hour, taking it out after natural cooling to obtain a heat-conducting aluminum-based sheet;

[0027] Step 5, spraying heat-conducting silica gel and absolute ethanol on the surface of the heat-conduc...

Embodiment 2

[0036] A kind of multi-layer heat conduction type photovoltaic backplane material, its steps are as follows:

[0037] Step 1, adding graphene powder into absolute ethanol, adding polyvinylpyrrolidone and ultrasonically stirring to form a uniform suspension;

[0038] Step 2, adding foaming agent and filler to the uniform suspension to obtain a mixed solution, and then performing vacuum distillation for 30 minutes to obtain a concentrated solution;

[0039] Step 3, adding deionized water to the concentrated solution, ultrasonically stirring evenly, and performing a second vacuum distillation for 60 minutes to obtain a thermally conductive suspension;

[0040] Step 4, cleaning the ultra-thin aluminum sheet, dipping and pulling for 3 hours, sealing, heating and pressurizing for 3 hours, taking it out after natural cooling to obtain a thermally conductive aluminum-based sheet;

[0041] Step 5, spraying heat-conducting silica gel and absolute ethanol on the surface of the heat-cond...

Embodiment 3

[0050] A kind of multi-layer heat conduction type photovoltaic backplane material, its steps are as follows:

[0051] Step 1, adding graphene powder into absolute ethanol, adding polyvinylpyrrolidone and ultrasonically stirring to form a uniform suspension;

[0052] Step 2, adding foaming agent and filler to the uniform suspension to obtain a mixed solution, and then performing vacuum distillation for 20 minutes to obtain a concentrated solution;

[0053] Step 3, adding deionized water to the concentrated solution, ultrasonically stirring evenly, and performing a second vacuum distillation for 50 minutes to obtain a thermally conductive suspension;

[0054] Step 4, cleaning the ultra-thin aluminum sheet, dipping and pulling for 2 hours, sealing, heating and pressurizing for 2 hours, taking it out after natural cooling to obtain a thermally conductive aluminum-based sheet;

[0055] Step 5, spraying heat-conducting silica gel and absolute ethanol on the surface of the heat-cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com