A device capable of reducing the circumferential temperature difference between the large-diameter motor coil and the iron core

A technology with iron core circumference and large diameter, applied in electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve the problem that the circumferential uniformity of airflow cannot be effectively improved, the circumferential temperature difference of the motor cannot be effectively reduced, and the circumferential uniformity of wind speed cannot be achieved. distribution and other issues, to ensure the uniformity of heat dissipation, improve the heat dissipation effect, and be easy to process and manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

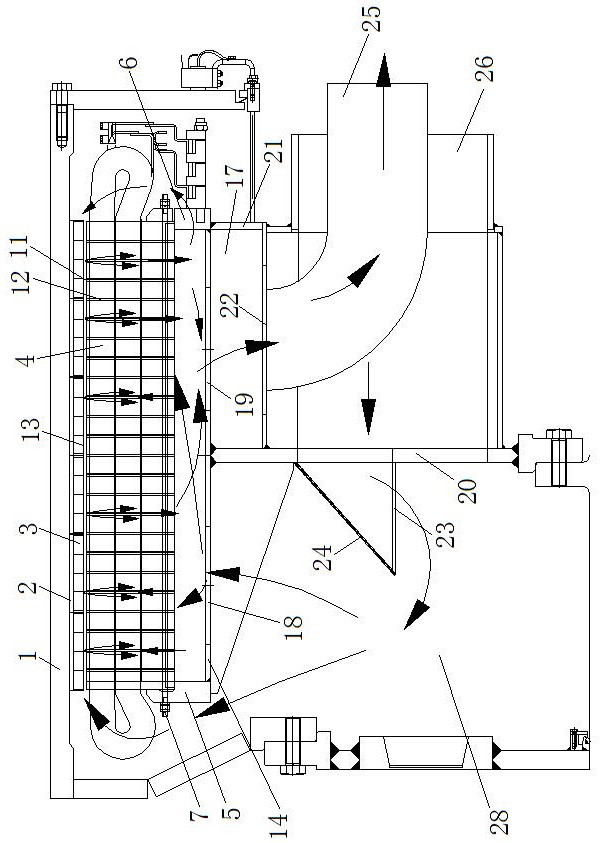

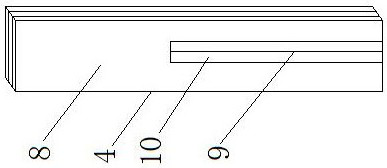

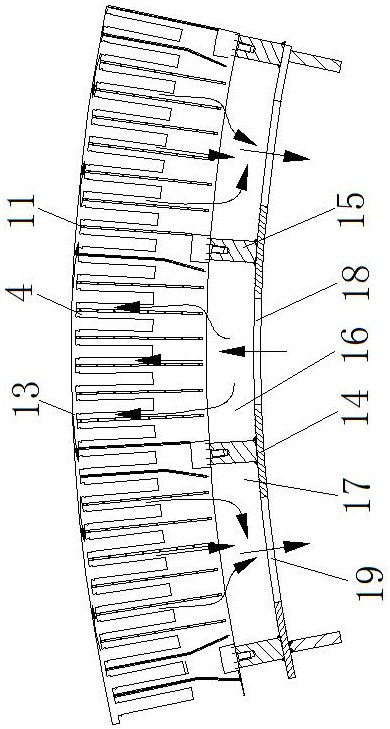

[0034] see Figure 1-Figure 5 , a device for reducing the circumferential temperature difference between a large-diameter motor coil and an iron core, comprising a rotor frame 1, a rotor core 2 mounted on the rotor frame 1, and a plurality of rotor magnets 3 arranged axially along the rotor core 2, It also includes a multi-stage stator core section 4, a first iron core pressing plate 5, a second iron core pressing plate 6, and a tension screw 7. The stator iron core section 4 is formed by stacking silicon steel sheets 8, and the silicon steel sheets 8 are provided with holes for placing In the slot body 10 of the stator coil 9, a stator channel steel 11 is connected between any two adjacent stator core segments 4, and the two stator core segments 4 and the stator channel steel 11 form a stator ventilation groove for cooling medium circulation 12. The tightening screw 7 runs through the multi-stage stator core segment 4, one end of the tightening screw 7 is fixedly connected to...

Embodiment 2

[0037] see Figure 1-Figure 5 , a device for reducing the circumferential temperature difference between a large-diameter motor coil and an iron core, comprising a rotor frame 1, a rotor core 2 mounted on the rotor frame 1, and a plurality of rotor magnets 3 arranged axially along the rotor core 2, It also includes a multi-stage stator core section 4, a first iron core pressing plate 5, a second iron core pressing plate 6, and a tension screw 7. The stator iron core section 4 is formed by stacking silicon steel sheets 8, and the silicon steel sheets 8 are provided with holes for placing In the slot body 10 of the stator coil 9, a stator channel steel 11 is connected between any two adjacent stator core segments 4, and the two stator core segments 4 and the stator channel steel 11 form a stator ventilation groove for cooling medium circulation 12. The tightening screw 7 runs through the multi-stage stator core segment 4, one end of the tightening screw 7 is fixedly connected to...

Embodiment 3

[0044] see Figure 1-Figure 5 , a device for reducing the circumferential temperature difference between a large-diameter motor coil and an iron core, comprising a rotor frame 1, a rotor core 2 mounted on the rotor frame 1, and a plurality of rotor magnets 3 arranged axially along the rotor core 2, It also includes a multi-stage stator core section 4, a first iron core pressing plate 5, a second iron core pressing plate 6, and a tension screw 7. The stator iron core section 4 is formed by stacking silicon steel sheets 8, and the silicon steel sheets 8 are provided with holes for placing In the slot body 10 of the stator coil 9, a stator channel steel 11 is connected between any two adjacent stator core segments 4, and the two stator core segments 4 and the stator channel steel 11 form a stator ventilation groove for cooling medium circulation 12. The tightening screw 7 runs through the multi-stage stator core segment 4, one end of the tightening screw 7 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com