Supercritical carbon dioxide boiler cooling wall matched with non-uniform thermal load

A carbon dioxide and cooling wall technology, applied in steam boilers, lighting and heating equipment, combustion methods, etc., can solve the problems of reducing the maximum temperature of the pipe wall, reducing the circumferential temperature difference of the cooling pipe wall, etc., to reduce the circumferential temperature difference of the wall, The effect of prolonging the effective life and reducing the circumferential stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

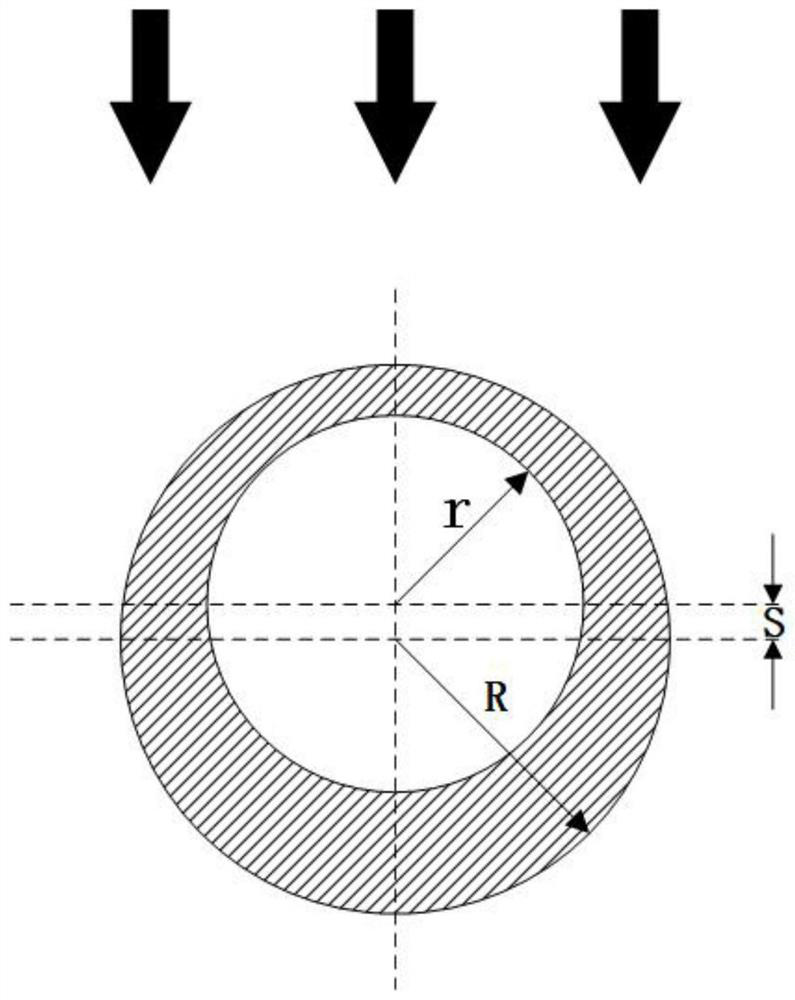

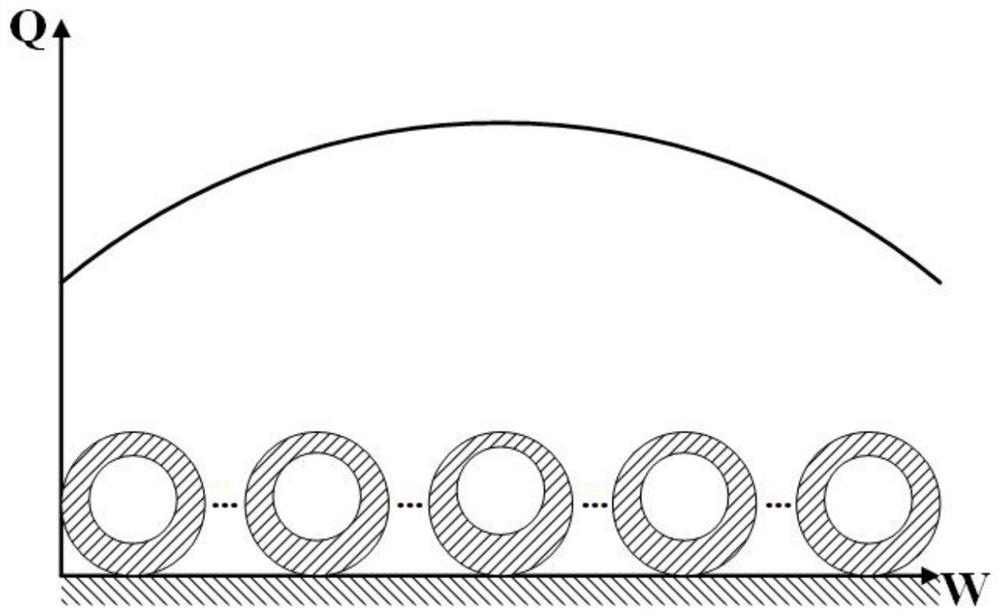

[0051] The maximum proportion of radiative heat transfer in furnace heat transfer reaches 95%. Each cooling stave tube has a fire side and a backfire side. The radiant heat transfer to the fire side tube wall is the largest, and it gradually decreases along the two sides of the tube wall. Small until the heat radiation received by the backfire side is minimal. The thickness of the traditional cooling wall tube wall is the same, which cannot be well adapted to the actual working conditions of circumferential non-uniform heat transfer, resulting in a large circumferential temperature difference of the tube wall, resulting in a large circumferential stress, which is not conducive to the long-term safe use of the tube, and the opposite fire The heat exchange effect at the maximum heat radiation on the side is not good enough, which leads to the high temperature of the maximum tube wall, which is prone to over-temperature tube explosion, which affects the safe operation. In additio...

Embodiment 2

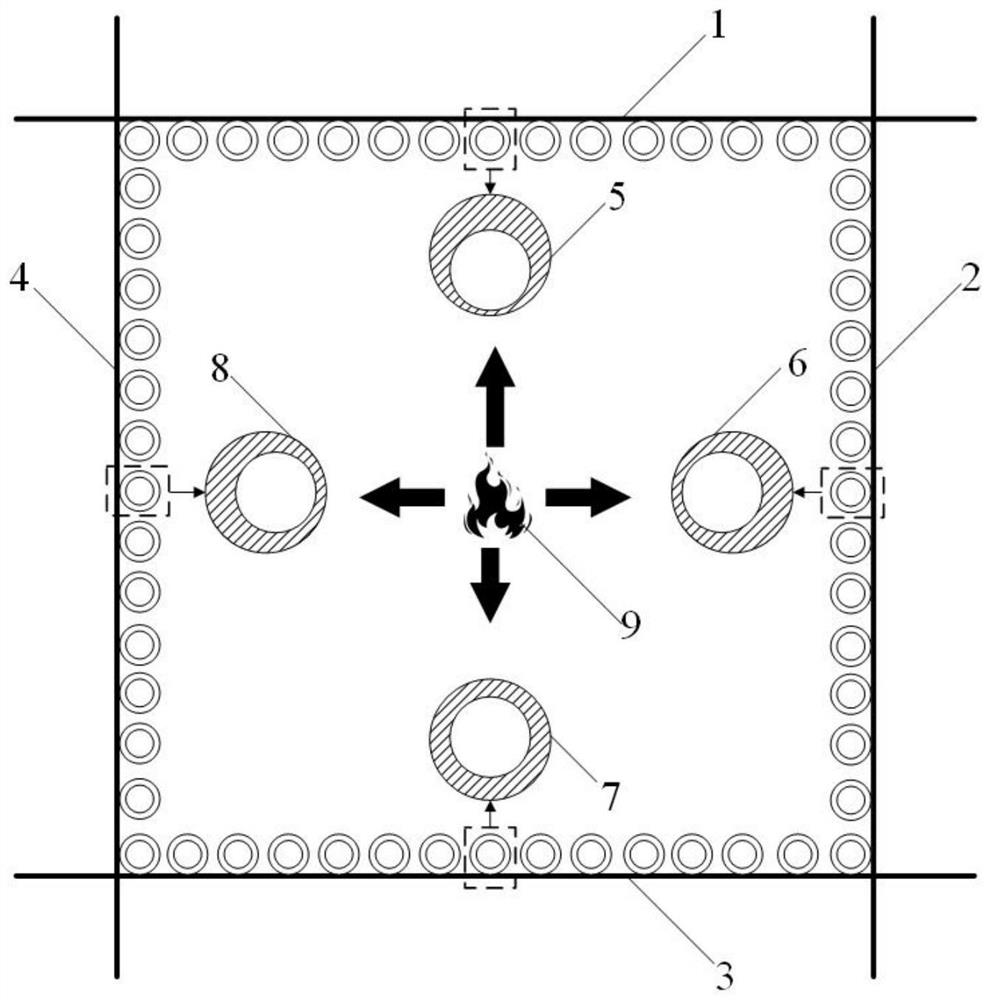

[0070] In this embodiment, a supercritical carbon dioxide boiler cooling wall matching the non-uniform heat load of the above-mentioned embodiment 1 is used to form a supercritical carbon dioxide boiler cooling chamber, which is used as S-CO 2 Boiler cooling.

[0071] A second aspect of the present application provides a supercritical carbon dioxide boiler cooling chamber, comprising:

[0072] The above-mentioned supercritical carbon dioxide boiler cooling wall matched with non-uniform heat load, the supercritical carbon dioxide boiler cooling chamber is composed of the boiler cooling wall enclosed;

[0073] The furnace flame area is composed of the flame ejected by the boiler furnace burner, and the thermal radiation energy is absorbed by the cooling wall of the eccentric tube around the boiler.

[0074] As an optional embodiment of the present application, optionally, the cooling chamber of the supercritical carbon dioxide boiler includes:

[0075] The front wall cooling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com