Construction method of a steel bar bending device

A steel bar bending and construction method technology, applied in the field of steel bar engineering technology construction, to achieve the effect of increasing the force arm, saving force, and enhancing the integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

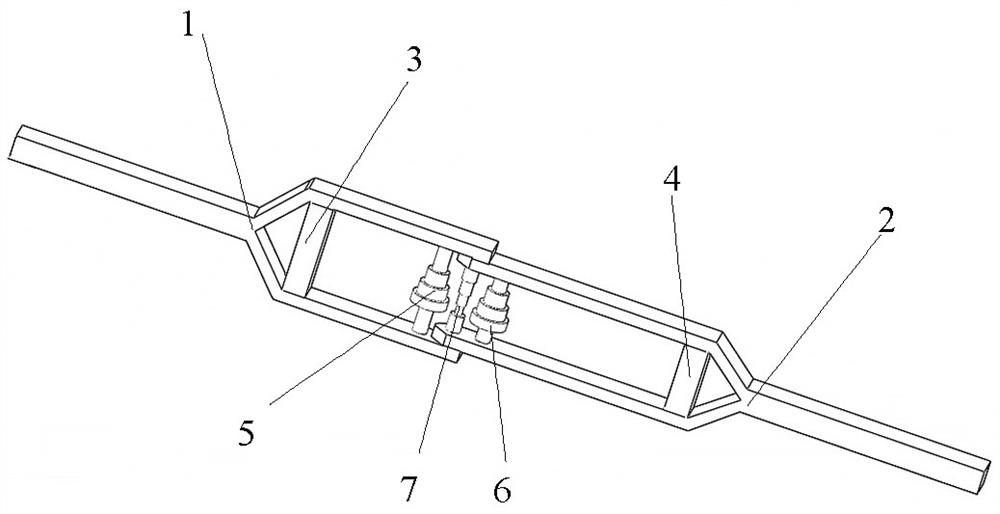

[0035] Such as figure 1 A steel bar bending device shown includes a main frame 1, a main auxiliary shaft 5 connected to the inside of the main frame 1, a sub-frame 2 connected to the end of the main frame 1, and a cross section connected to the intersection of the main frame 1 and the sub-frame 2. The bending mandrel 7 and the auxiliary auxiliary shaft 6 connected to the inside of the sub-frame 2; the bending mandrel 7 is rotationally connected to the main frame 1 and the sub-frame 2, the main auxiliary shaft 5 is rotationally connected to the main frame 1, and the auxiliary auxiliary shaft 6 is connected in rotation relative to the subframe 2; the diameter of the bending mandrel 7 is adapted to the design bending diameter of the steel bar 8, and the horizontal distance between the bending mandrel 7 and the main auxiliary shaft 5 and the auxiliary auxiliary shaft 6 is adapted to the bending diameter of the steel bar 8.

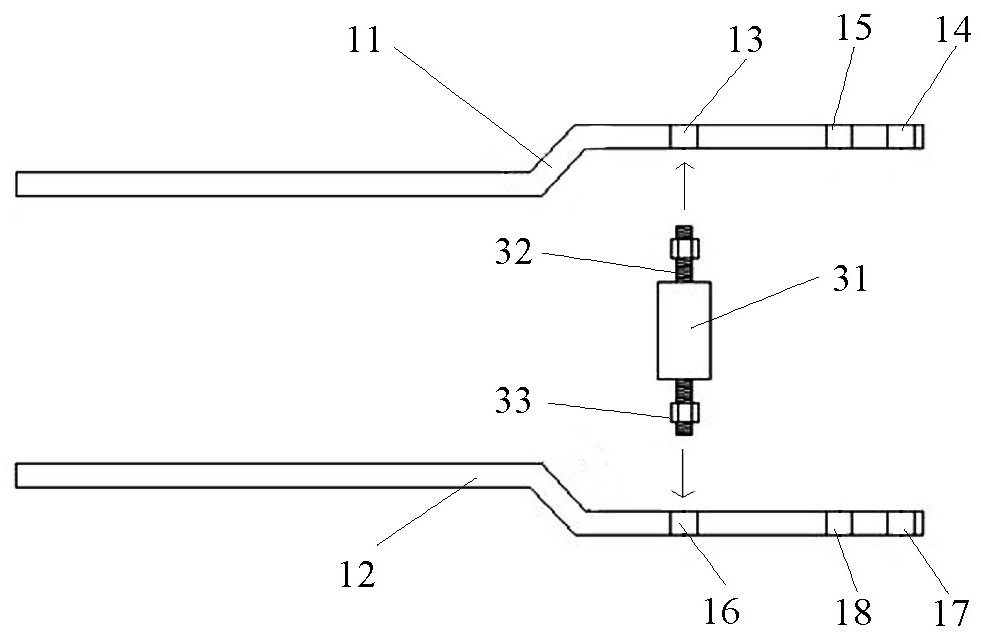

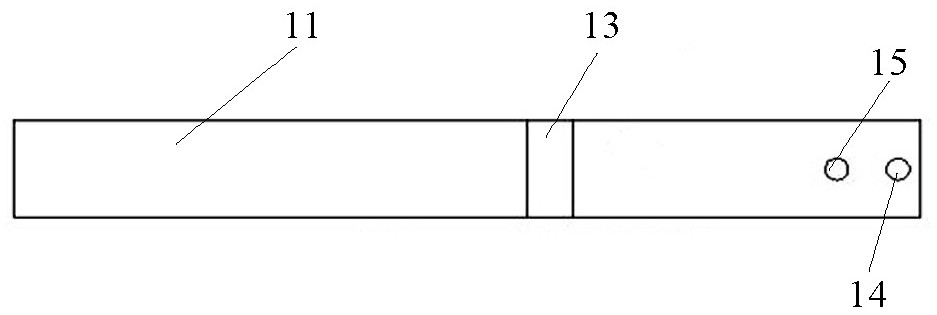

[0036] Such as figure 2 with image 3 Shown, main fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com