Rotating drum reinforcing pipe welding equipment and welding method

A technology for welding equipment and reinforced pipes, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve problems such as low welding efficiency, unstable welding quality, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples. But the protection scope of the present invention is not limited thereto.

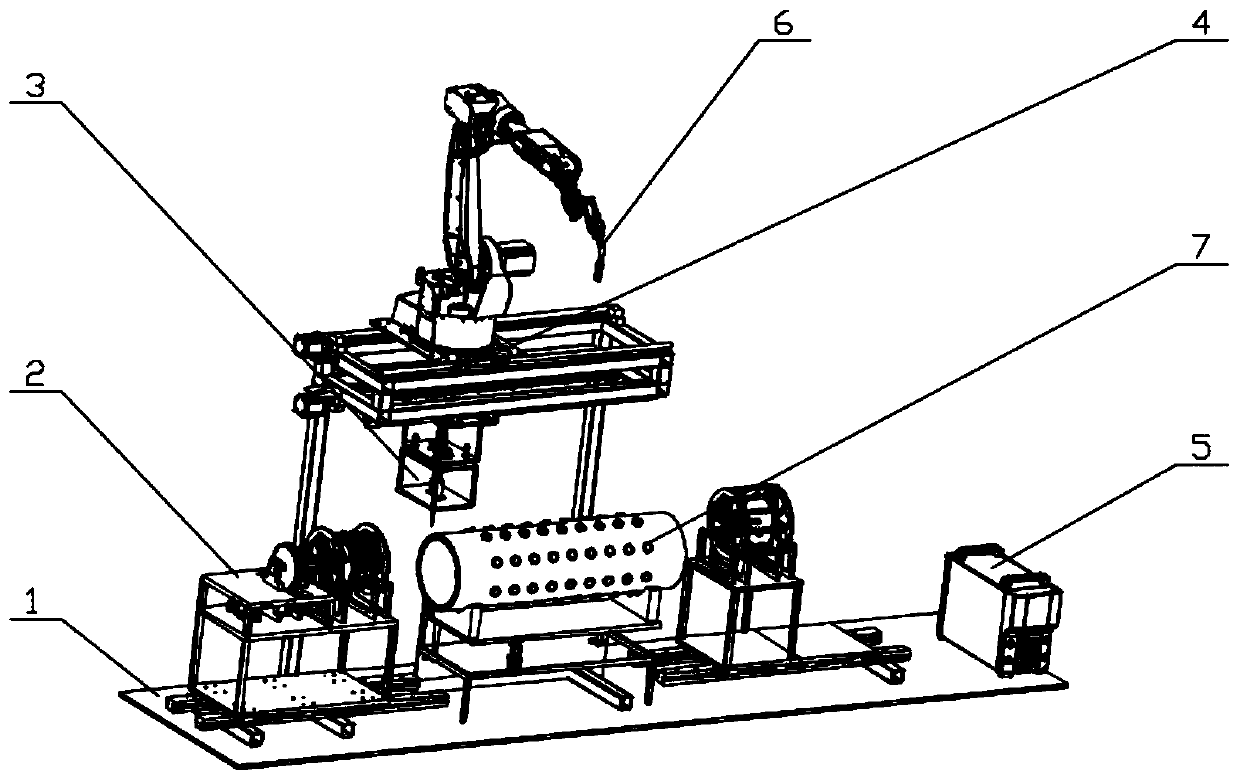

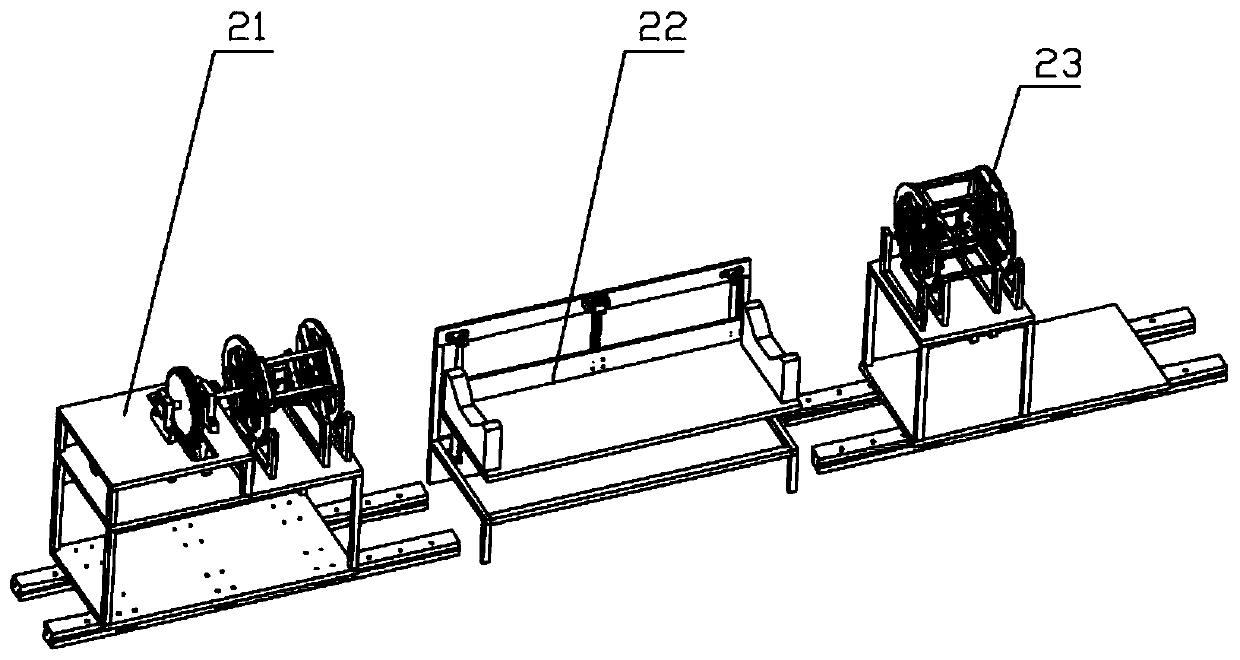

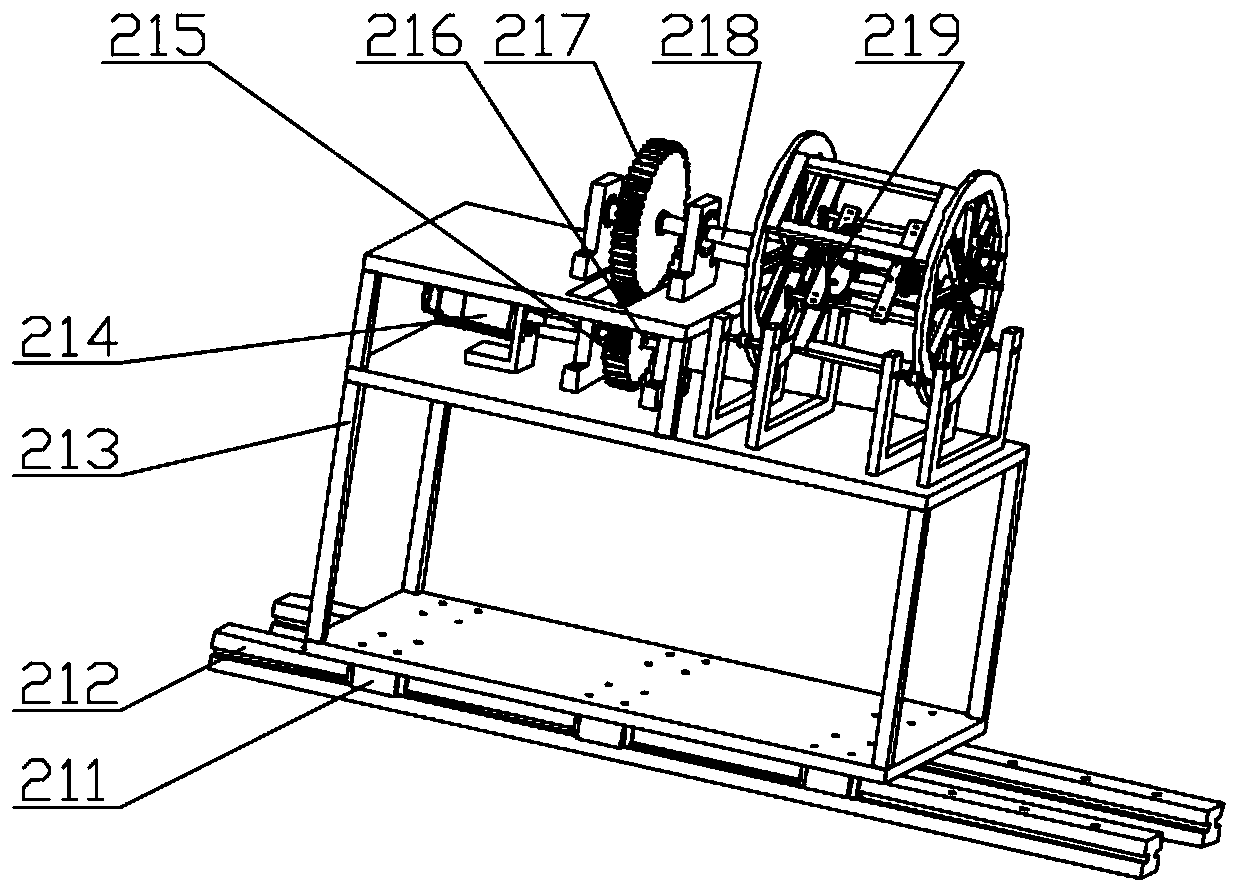

[0056] Such as figure 1 and Figure 19 As shown, a drum reinforced pipe welding equipment includes a bottom plate 1, a clamping part 2, a measuring part 3, a welding feed part 4, an electric welding machine 5 and a welding torch 6, and the clamping part 2 and the measuring part 3 are all installed on the bottom plate 1, the welding feeding part 4 is installed above the measuring part 3, the clamping part 2 is used for clamping the drum 7, and can drive the drum 7 to rotate , the measuring part 3 is used to measure the inclination and the center position of the strengthening tube 73 on the drum 7 in two mutually perpendicular directions, and the welding feeding part 4 is used to drive the welding torch 6 to feed, to realize The weld...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap