A kind of release agent for rubber molding industry and preparation method thereof

A technology for rubber molding and industrial use, which is applied in the field of release agent for rubber molding industry and its preparation, which can solve the problems of low release efficiency of release agent, achieve good release effect, improve overall quality, and excellent release effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

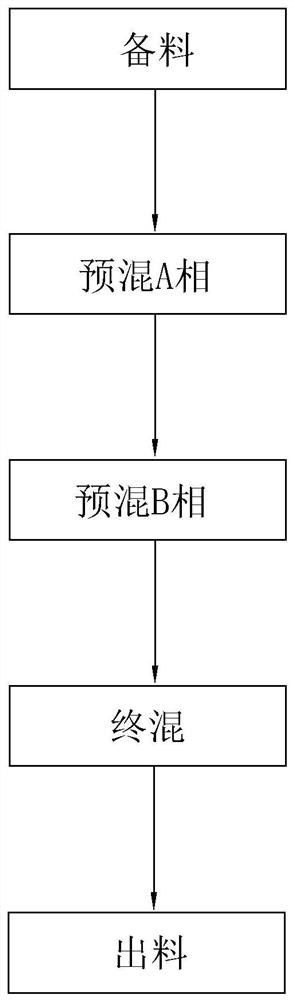

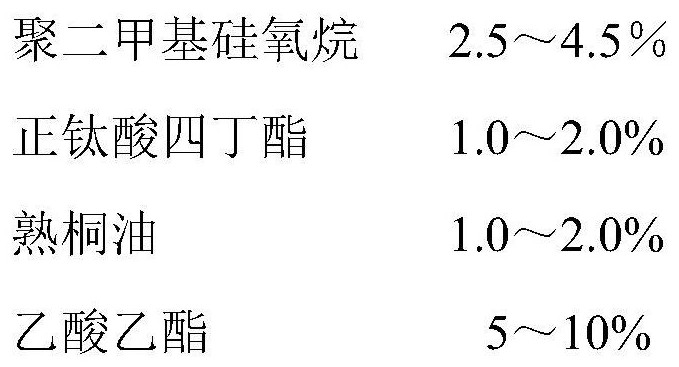

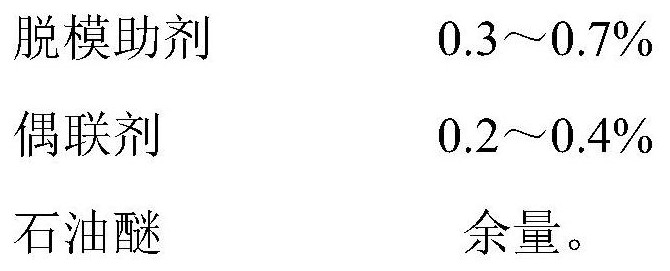

[0041] Embodiment 1-3: A mold release agent for rubber molding industry. The components and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0042] Step 1, preparing materials, weighing polydimethylsiloxane, tetrabutyl orthotitanate, cooked tung oil, ethyl acetate and petroleum ether according to the mass ratio;

[0043] Step 2, premix phase A, add ethyl acetate to cooked tung oil and stir to dissolve, mix evenly, stirring speed is 1500rpm, time is 10min, as phase A;

[0044]Step 3, premix phase B, add polydimethylsiloxane to petroleum ether, stir rapidly until completely dissolved, stirring speed is 1000rpm, time is 15min, as phase B;

[0045] Step 4, final mixing, add phase A into phase B during rapid stirring, stir until completely dissolved, stirring at 1500 rpm, for 10 minutes, mix evenly to obtain a mixture;

[0046] Step 5, discharge, stir the mixture clockwise, the stirring speed is 800rpm, at the same time, add...

Embodiment 4

[0050] Embodiment 4: A mold release agent for rubber molding industry. The difference from Embodiment 1 is that the viscosity of polydimethylsiloxane in step 3 is 200cs.

Embodiment 5

[0051] Embodiment 5: A mold release agent for rubber molding industry. The difference from Embodiment 1 is that the viscosity of polydimethylsiloxane in step 3 is 500cs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com