Novel traction device used for pre-stressed steel strands

A technology of prestressed steel strand and traction device, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc. It can solve the problems that the traction machine cannot be used conveniently, achieve reliable and efficient traction process, and improve contact The effect of saving area and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

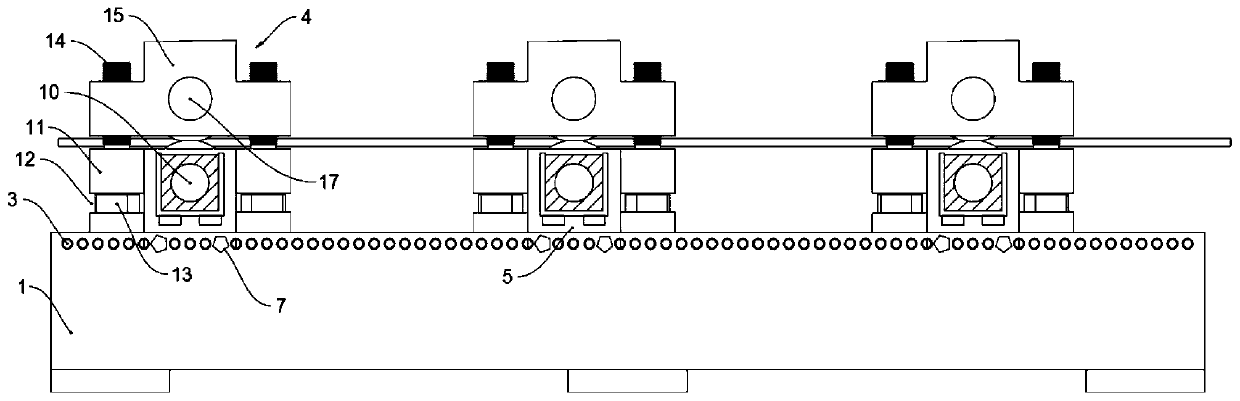

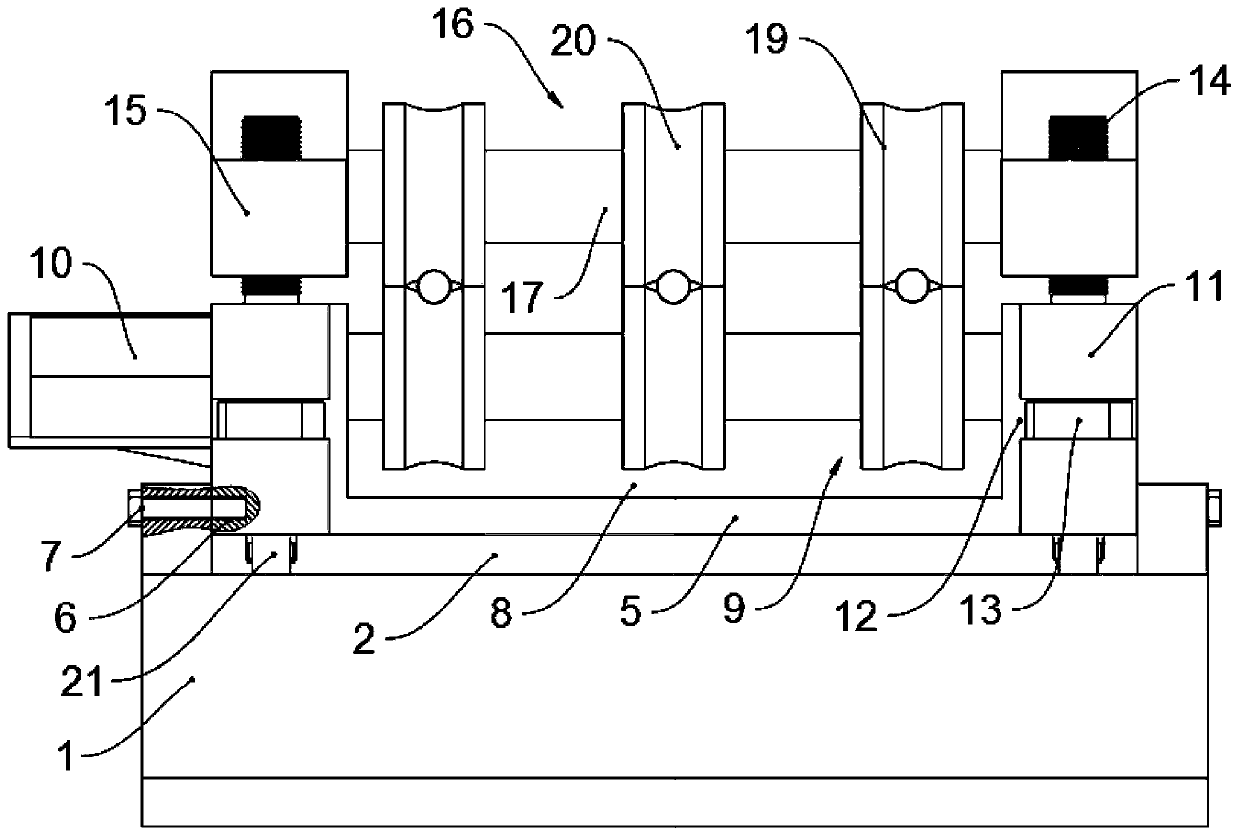

[0027] Such as Figure 1 to Figure 3 As shown, this embodiment provides a new type of traction device for prestressed steel strands, including a base 1, the upper surface of the base 1 is provided with a moving groove 2, and the front and rear ends of the moving groove 2 pass through the base 1 On the surface, a row of through holes 3 are horizontally provided on the left and right sides of the moving groove 2, and all the through holes 3 are evenly distributed in the horizontal direction and pass through the surface of the base 1. The upper surface of the base 1 is provided with a number of holes installed in the moving groove 2. The traction mechanism 4, the traction mechanism 4 includes the lower abutment 5 that can move in the moving groove 2, and the bottom of the left and right sides of the lower abutment 5 is provided with some positioning holes 6 that can coincide with the center line of the through hole 3, and the positioning holes 6 are inserted There is a fastener 7...

Embodiment 2

[0030] Such as Figure 1 to Figure 3 As shown, this embodiment is further optimized on the basis of embodiment 1, specifically:

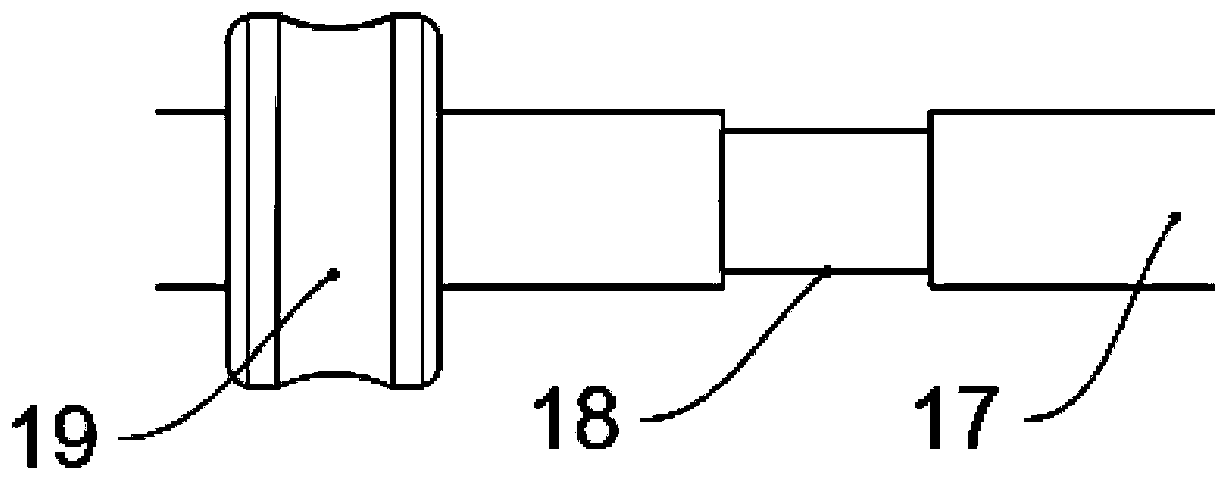

[0031] The upper traction group 16 and the lower traction group 9 have the same structure. The upper traction group 16 includes a rotating shaft 17 arranged in the middle of the upper base 15. The rotating shaft 17 is uniformly provided with a number of ring grooves 18 in the direction of the axis, and a traction wheel is clamped in the ring groove 18. 19.

[0032] In this embodiment, the design of multiple pairs of traction wheels 19 allows the entire traction device to simultaneously pull multiple steel strands, and the setting of the ring groove 18 can prevent the traction wheels 19 from moving left and right, ensuring that the traction wheels 19 are more stable and reliable during the traction process , effectively improving the practicability of the traction mechanism 4 .

Embodiment 3

[0034] Such as Figure 1 to Figure 3 As shown, this embodiment is further optimized on the basis of embodiment 1, specifically:

[0035]The central part of the surface of the traction wheel 19 is provided with a traction groove 20 in the circumferential direction.

[0036] In this embodiment, the traction groove 20 can increase the contact area between the surface of the traction wheel 19 and the surface of the steel strand, thereby increasing the friction force and making the traction process more reliable and efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com