Hydraulic locking device for ram bop

A technology of ram blowout preventer and locking device, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of easy wear and tear of the clutch sprocket, difficulty in unlocking, and large structural size, etc. Reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

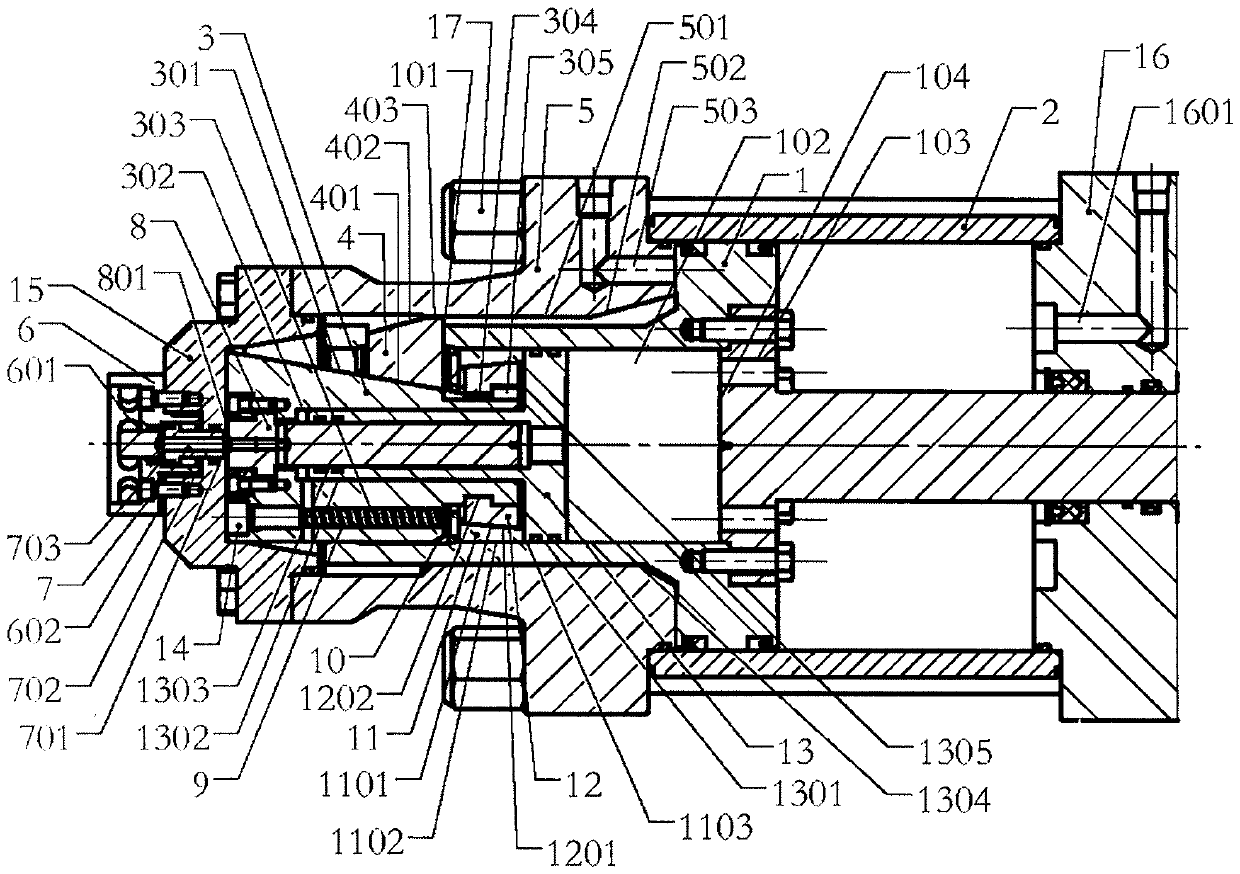

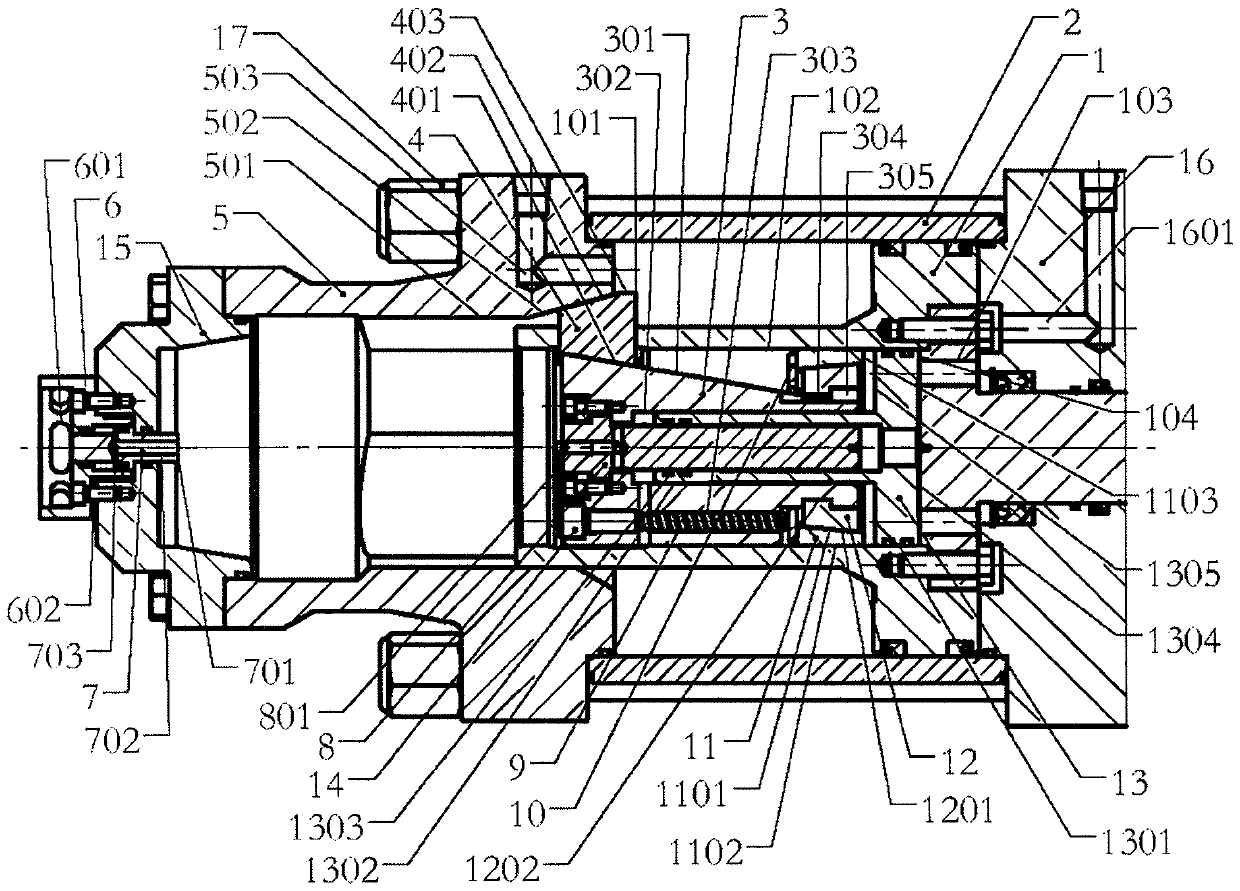

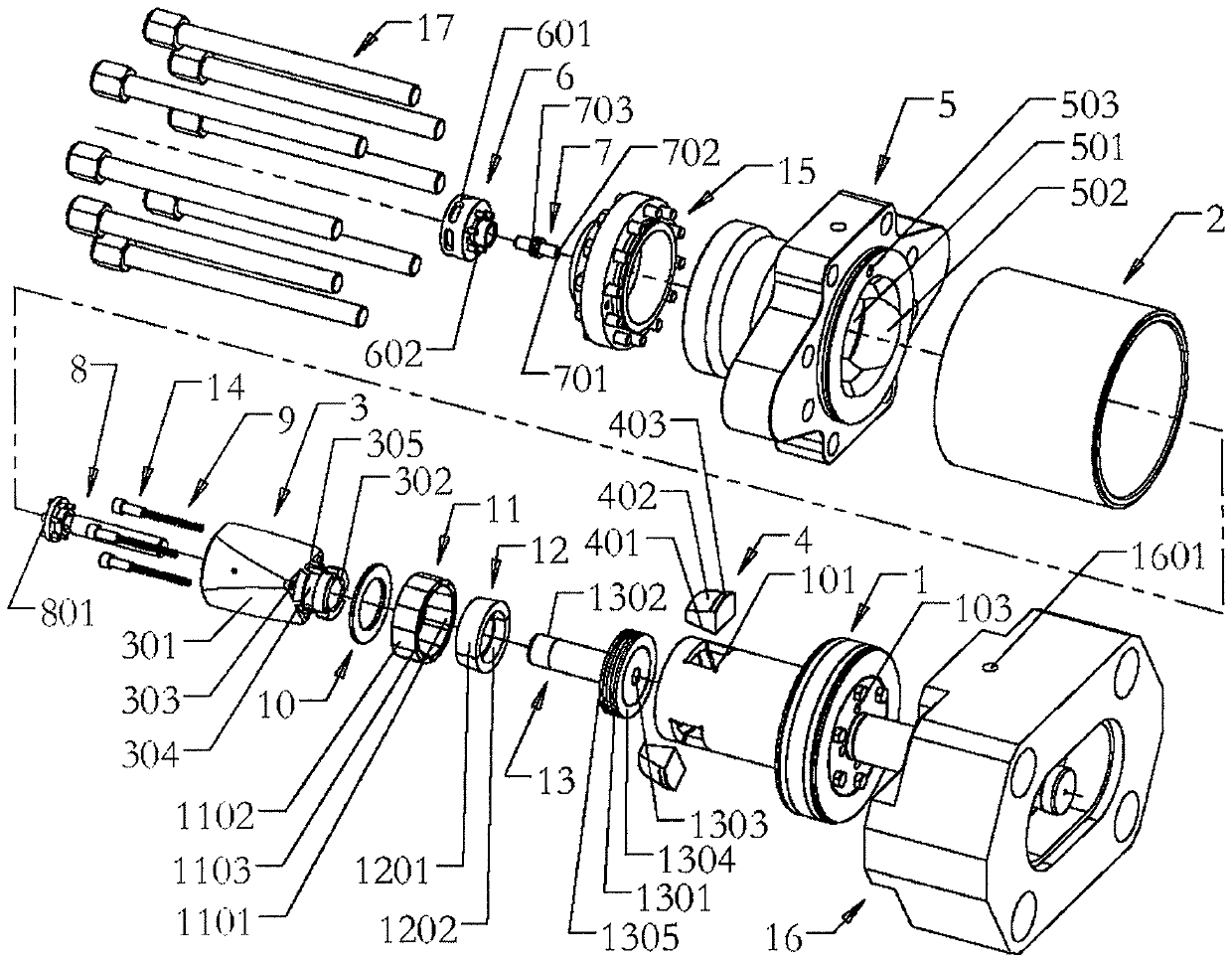

[0048] The invention will be described in detail below with reference to the accompanying drawings.

[0049] The locking device is composed of a main locking mechanism and a synchronous locking mechanism. The main locking mechanism includes a piston assembly 1, a wedge sleeve 3, a wedge block 4, and a liquid lock cylinder 5. The wedge block 4 is assembled on the piston assembly 1. In the front square hole 101, the lower inclined surface 401 of the wedge block 4 is in contact with the inclined surface 301 of the wedge sleeve 3. The wedge sleeve 3 and the wedge block 4 adopt a larger wedge angle design, and the wedge block 4 follows the axial direction of the piston 1. Movement, so that the top of the wedge 4 moves back and forth in the slideway of the liquid lock cylinder 5. At the front end of the main locking mechanism, a synchronous locking mechanism composed of a cone ring 12 preloaded by a spring 9 and a cone disc 11 is provided. corner design. The locking action of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com