Simulated CO2 dry fracturing working medium mixed transportation experimental device and method

An experimental device and experimental method technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., to achieve the effect of safe and reliable operation and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Referring to the accompanying drawings and embodiments, the present invention is further described in detail.

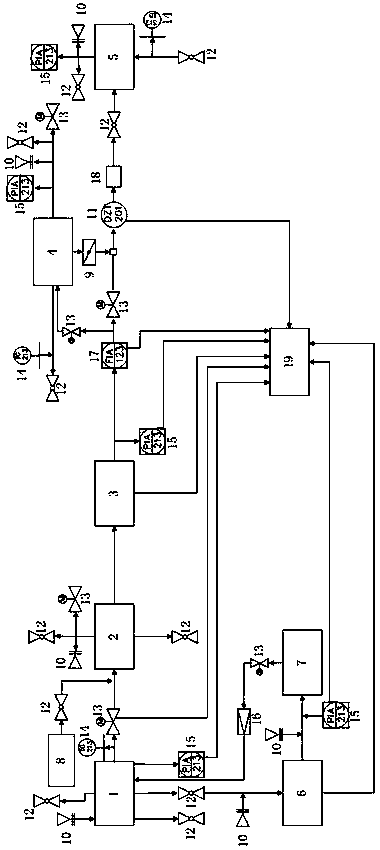

[0035] figure 1 Medium: Liquid CO 2 Storage tank 1, liquid addition pump 8, liquid-gas separator 2, booster pump 3, closed sand tank 4, recovery tank 5, gasification pump 6, and gasifier 7 are connected through pipelines in sequence, and the PLC control system 19 and liquid Gas separator 2, gasification pump 6, density sensor 11, electric valve 13, temperature sensor 14, pressure sensor 15 are connected, and liquid CO 2 Liquid CO in storage tank 1 2 After mixing with the proppant and quartz sand injected by the liquid addition pump 8, the gas phase is separated by the liquid-gas separator 2, and then a small part enters the closed sand tank 4 after being pressurized by the booster pump 3, and the main part enters the closed sand tank 4 through the pipeline. 4 The lower part is mixed with the proppant, and finally enters the recovery tank 5, and the gasifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com